Unveiling the Anatomy of Power: A Deep Dive into the Essential Parts of a Truck Vehicle

Unveiling the Anatomy of Power: A Deep Dive into the Essential Parts of a Truck Vehicle Typestruck.Guidemechanic.com

Trucks are the undisputed workhorses of our modern world, tirelessly transporting goods, materials, and equipment across vast distances. From the agile light-duty pickups navigating urban jungles to the colossal semi-trucks traversing highways, these vehicles are engineering marvels. But have you ever stopped to consider what truly makes them tick? Understanding the intricate parts of a truck vehicle is not just for mechanics; it’s crucial for owners, operators, and anyone who relies on these machines.

Based on my extensive experience in the automotive industry, a comprehensive grasp of truck components empowers you to make informed decisions about maintenance, repairs, and even purchasing. It enhances safety, optimizes performance, and ultimately saves you significant time and money. This in-depth guide will meticulously break down the core systems and essential parts that constitute these powerful machines, ensuring you gain a profound appreciation for their complexity and functionality.

Unveiling the Anatomy of Power: A Deep Dive into the Essential Parts of a Truck Vehicle

Why Every Truck Enthusiast and Owner Needs to Understand Truck Parts

Before we dive into the specifics, let’s establish why this knowledge is so vital. A truck isn’t just a collection of metal and wires; it’s an integrated system where each part plays a critical role in its overall operation. Neglecting one component can have a domino effect, compromising safety and leading to costly breakdowns.

Understanding the fundamental truck components allows you to communicate more effectively with technicians, identify potential issues early, and even perform basic troubleshooting. It transforms you from a passive user into an active participant in your truck’s well-being. This proactive approach is key to maximizing vehicle lifespan and ensuring reliability.

The Heartbeat of the Beast: Engine and Related Systems

At the core of every truck lies its engine, the powerhouse that converts fuel into mechanical energy. This complex system is far more than just a block of metal; it’s an orchestration of numerous precision-engineered engine parts working in harmony. From ignition to exhaust, each component is vital for power generation and efficiency.

1. The Engine Block and Internal Components

The engine block serves as the main housing for the engine’s internal moving parts. It’s typically cast from iron or aluminum, designed to withstand immense pressure and heat. Within this block, you’ll find critical components like pistons, connecting rods, and the crankshaft.

Pistons move up and down within cylinders, compressing the air-fuel mixture and driving the crankshaft. The crankshaft, in turn, converts this linear motion into rotational energy, which is then transmitted to the wheels. The camshaft, another crucial internal part, controls the opening and closing of the engine’s valves, ensuring proper air intake and exhaust gas expulsion. Understanding these fundamental truck engine parts is the first step in appreciating how power is generated.

2. The Fuel System

The fuel system is responsible for storing, filtering, and delivering fuel to the engine in precise amounts. It typically comprises the fuel tank, fuel pump, fuel filter, and fuel injectors. The fuel pump draws fuel from the tank, sending it under pressure through the fuel filter, which removes contaminants.

Pro tips from us: Always use high-quality fuel filters and replace them according to manufacturer specifications. A clogged fuel filter can significantly reduce engine performance and even damage the fuel pump or injectors. The fuel injectors then atomize the fuel and spray it into the combustion chambers or intake manifold, ensuring efficient burning.

3. The Cooling System

Engines generate an immense amount of heat during operation, and without an effective cooling system, they would quickly overheat and seize. Key cooling system components include the radiator, water pump, thermostat, and coolant hoses. The water pump circulates coolant, a mixture of water and antifreeze, through the engine block and cylinder head.

The hot coolant then flows to the radiator, where heat is dissipated into the ambient air. The thermostat regulates the engine’s operating temperature by controlling the flow of coolant. Common mistakes to avoid are neglecting coolant flushes or ignoring an overheating engine. These can lead to severe engine damage, requiring expensive repairs.

4. The Exhaust System

Once fuel is burned, the resulting exhaust gases must be safely expelled from the engine. The exhaust system manages this process, reducing noise and harmful emissions. It includes the exhaust manifold, catalytic converter (for emission control), diesel particulate filter (DPF) for diesel trucks, and the muffler.

The exhaust manifold collects gases from the engine cylinders and directs them to the rest of the system. Catalytic converters and DPFs are essential for meeting environmental regulations by transforming pollutants into less harmful substances. The muffler then dampens the loud exhaust noise, ensuring a quieter operation. Regular inspection for leaks or damage is vital for both performance and environmental compliance.

5. The Air Intake System

For combustion to occur, the engine needs a continuous supply of clean air. The air intake system brings air into the engine, filtering it to prevent contaminants from entering. This system typically includes the air filter, intake manifold, and often a turbocharger or supercharger in modern trucks.

The air filter is crucial for trapping dust, dirt, and debris before they can reach the engine’s delicate internal parts. A dirty air filter can restrict airflow, leading to reduced power and fuel efficiency. Turbochargers and superchargers are designed to force more air into the engine, significantly boosting power output, especially in heavy-duty truck parts applications.

Power Transfer: Drivetrain Components

Once the engine generates power, the drivetrain is responsible for transmitting that power to the wheels, allowing the truck to move. This system is a complex network of drivetrain components engineered to handle immense torque and varying loads.

1. The Transmission System

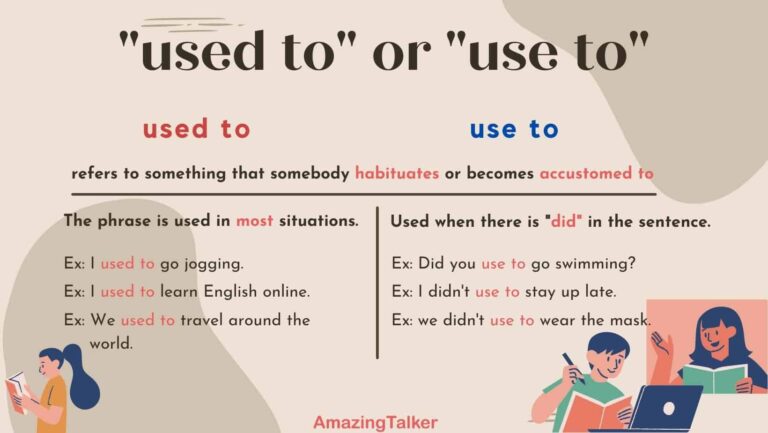

The transmission is a vital component that manages the engine’s power output, allowing the driver to select different gear ratios. This ensures the engine operates efficiently across various speeds and load conditions. Trucks can have manual, automatic, or automated manual transmissions (AMTs).

Manual transmissions require the driver to manually shift gears using a clutch pedal and gear stick. Automatic transmissions shift gears automatically, providing a smoother driving experience. AMTs offer a blend, providing automatic shifting with the efficiency of a manual. Proper maintenance, including regular fluid changes, is paramount for transmission longevity.

2. The Clutch

For trucks with manual transmissions, the clutch is an indispensable component. It acts as an intermediary, temporarily disengaging the engine from the transmission when changing gears or coming to a stop. This allows for smooth gear shifts without grinding.

Based on my experience, a properly functioning clutch is essential for safe and efficient driving. Signs of a worn clutch include slipping (engine revs without increasing speed), difficulty shifting, or a burning smell. Addressing these issues promptly can prevent more extensive and costly damage to the transmission.

3. The Driveshaft

The driveshaft, also known as a propeller shaft, is a long, rotating tube that transmits power from the transmission to the differential. It’s designed to withstand high rotational forces and must be balanced precisely to prevent vibrations. In multi-axle trucks, there might be several driveshafts connecting various differentials.

Universal joints (U-joints) are found at each end of the driveshaft, allowing for flexibility and articulation as the suspension moves. Regular inspection of U-joints for wear or damage is a simple but critical maintenance step to prevent catastrophic failure while driving.

4. Axles and Differentials

Axles are shafts that connect the wheels to the drivetrain, supporting the weight of the truck and its cargo. Trucks typically have a front axle and one or more rear axles. The differential, housed within the axle assembly, is a gear system that allows the wheels on the same axle to rotate at different speeds.

This capability is crucial when a truck turns, as the outer wheel needs to travel a greater distance than the inner wheel. Without a differential, the wheels would skid, leading to tire wear and handling issues. Regular differential fluid changes are essential to lubricate these intricate gears and prevent premature wear, especially in commercial vehicle parts.

5. Wheels and Tires

While seemingly straightforward, wheels and tires are among the most critical parts of a truck vehicle for safety and performance. Wheels provide the mounting point for tires and are designed to bear immense loads. Tires provide traction, absorb road shock, and support the vehicle’s weight.

Pro tips from us: Always ensure your tires are properly inflated, regularly inspected for wear and damage, and rotated according to manufacturer guidelines. Correct tire pressure not only improves fuel economy but also significantly reduces the risk of blowouts. The type of tire – all-season, all-terrain, or specialized for heavy loads – also plays a crucial role in the truck’s overall capability.

Control and Safety: Braking and Steering Systems

No matter how powerful a truck is, its ability to stop and maneuver safely is paramount. The braking and steering systems are engineered to provide precise control, protecting the driver, cargo, and other road users.

1. The Brake System

The brake system is arguably the most critical safety feature on any truck. Most heavy-duty trucks utilize air brakes, while lighter trucks might use hydraulic systems. Both systems aim to convert the truck’s kinetic energy into heat, slowing or stopping the vehicle.

Air brake systems involve an air compressor, air tanks, foot valve, brake chambers, and brake shoes/pads that press against drums or discs. Anti-lock Braking Systems (ABS) are standard, preventing wheels from locking up during hard braking, which helps maintain steering control. Regular brake inspections and adjustments are non-negotiable for safe operation. Common mistakes to avoid include ignoring squealing brakes or a soft pedal, as these are clear indicators of potential failure.

2. The Steering System

The steering system allows the driver to control the direction of the truck. It typically consists of the steering wheel, steering column, steering gearbox (or rack-and-pinion in lighter trucks), and various linkages (tie rods, drag link). Power steering systems, common in all modern trucks, use hydraulic or electric assistance to make steering effortless, especially with heavy loads.

A well-maintained steering system provides precise control and a comfortable driving experience. Any looseness, excessive play, or unusual noises in the steering should be investigated immediately. These could indicate worn components that compromise steering accuracy and safety.

Comfort and Stability: Suspension and Chassis

The chassis provides the structural backbone of the truck, while the suspension system ensures a smooth ride and stable handling, even under challenging conditions. These truck parts are fundamental to both operational capability and driver comfort.

1. The Chassis Frame

The chassis frame is the rigid structure that supports all other components of the truck, including the engine, transmission, body, and cargo. It’s designed to withstand immense torsional stress and bending forces. Heavy-duty trucks often feature ladder frames made of robust steel beams, providing maximum strength and durability.

The integrity of the chassis is vital for the truck’s structural stability and load-carrying capacity. Any damage to the frame can compromise the entire vehicle, making regular inspections for cracks or corrosion essential, especially for semi-truck parts.

2. The Suspension System

The suspension system absorbs shocks and vibrations from the road, providing a comfortable ride and maintaining tire contact with the road surface for optimal traction. It comprises components such as springs (leaf springs, coil springs, or air springs), shock absorbers, and various linkages.

Leaf springs are common in heavy-duty applications due to their durability and load-carrying capacity. Air springs offer a smoother ride and adjustable ride height, often found in modern commercial vehicles. Shock absorbers dampen spring oscillations, preventing excessive bouncing. A well-functioning suspension system is critical for stability, handling, and protecting the cargo.

3. Cab Components

The cab is the driver’s office, and its components are designed for comfort, ergonomics, and safety. This includes the seats, dashboard, instrument panel, steering wheel, and the heating, ventilation, and air conditioning (HVAC) system. Modern truck cabs are increasingly equipped with advanced electronics and connectivity features.

The driver’s seat, often air-suspended, is designed for long-haul comfort, reducing fatigue. The dashboard provides vital information about the truck’s operation, while the HVAC system maintains a comfortable interior climate. These cab components directly impact driver productivity and well-being.

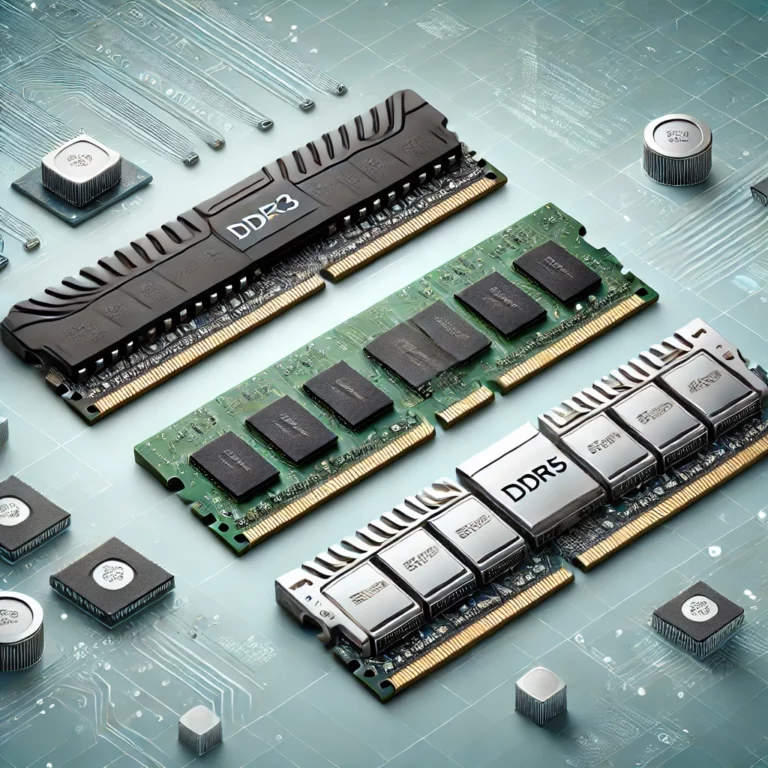

The Nerve Center: Electrical System

The electrical system is the unseen network that powers everything from the engine’s ignition to the lights and onboard electronics. Without a robust electrical system, the truck simply wouldn’t function.

1. Battery and Alternator

The battery provides the initial surge of power needed to start the engine and powers accessories when the engine is off. Once the engine is running, the alternator takes over, generating electricity to power the truck’s electrical systems and recharge the battery.

Pro tips from us: Regularly check battery terminals for corrosion and ensure they are clean and tight. A failing alternator can lead to a dead battery and leave you stranded. These two components are the backbone of your truck’s electrical health.

2. Wiring Harness

The wiring harness is a complex network of wires and connectors that transmit electrical signals and power throughout the truck. It connects all electrical components, from sensors and lights to the engine control unit (ECU). Any damage to the wiring harness can lead to various electrical malfunctions.

3. Lighting System

The lighting system is crucial for visibility and safety, especially during night driving or adverse weather conditions. It includes headlights, taillights, turn signals, brake lights, marker lights, and interior lights. Modern trucks often use LED lighting for greater efficiency and longevity.

Common mistakes to avoid are driving with non-functional lights. This is not only illegal but also extremely dangerous. Regular checks of all lights should be part of your pre-trip inspection routine.

4. Sensors and ECUs

Modern trucks are equipped with a myriad of sensors that monitor various parameters, such as engine temperature, oil pressure, wheel speed, and exhaust gas levels. These sensors feed data to the Electronic Control Units (ECUs), which are essentially the truck’s computers.

The ECU processes this data and makes real-time adjustments to optimize engine performance, fuel efficiency, emissions, and safety systems. Understanding that these sophisticated truck components are constantly at work highlights the advanced engineering in today’s vehicles.

Auxiliary and Body Components

Beyond the core operational systems, trucks also feature various auxiliary and body parts that contribute to their specific functions and overall utility. These vary greatly depending on the truck’s intended use.

1. Fifth Wheel (for Semi-Trucks)

For semi-trucks, the fifth wheel is a critical coupling device that connects the tractor unit to the trailer. It allows for flexible articulation between the two, enabling the trailer to pivot during turns. The fifth wheel must be robustly constructed to safely bear the immense weight and forces exerted by the trailer.

Regular inspection and lubrication of the fifth wheel are paramount for preventing dangerous trailer detachment. This is a prime example of a specialized truck part vital for a specific type of commercial vehicle.

2. Trailer Connection Systems

Beyond the fifth wheel, trailers require electrical and air connections to the tractor. This includes air lines for the trailer’s brake system and electrical connectors for lights, ABS, and other auxiliary functions. These connections must be secure and free from leaks or damage to ensure safe trailer operation.

3. Body Panels and Fenders

Body panels, such as the hood, doors, and fenders, form the exterior shell of the truck. They provide aerodynamic styling, protect internal components from the elements, and contribute to the vehicle’s structural integrity. Fenders, in particular, protect the wheels and tires from road debris.

4. Mirrors and Wipers

Mirrors (side mirrors, convex mirrors) are essential for visibility, especially given the size and blind spots of trucks. Wipers ensure a clear view through the windshield during rain or snow. Properly adjusted mirrors and functional wipers are fundamental safety features.

5. Hydraulic Systems (for Dump Trucks, Cranes, etc.)

Many specialized trucks, such as dump trucks, garbage trucks, and those with cranes or liftgates, incorporate hydraulic systems. These systems use pressurized fluid to generate force, enabling them to lift heavy loads, operate attachments, or articulate various parts of the truck’s body. The hydraulic pump, cylinders, hoses, and fluid are all critical hydraulic truck parts that require specialized maintenance.

Pro Tips for Truck Part Maintenance and Longevity

Based on my years of working with various trucks, here are some actionable tips to ensure your truck’s components last longer and perform optimally:

- Adhere to Manufacturer’s Schedule: This is non-negotiable. Follow the recommended maintenance intervals for oil changes, filter replacements, fluid checks, and major inspections.

- Use Quality Parts: While cheaper alternatives might be tempting, investing in genuine or high-quality aftermarket truck components pays off in the long run. Inferior parts can fail prematurely, causing more damage and costing more in the end.

- Regular Visual Inspections: Make a habit of doing a quick walk-around and visual check before and after each trip. Look for leaks, loose wires, damaged tires, or anything out of the ordinary. This proactive approach can catch small problems before they escalate.

- Listen to Your Truck: Pay attention to unusual noises, vibrations, or smells. These are often the first indicators that something is amiss. Don’t ignore warning lights on your dashboard.

- Fluid Management: Regularly check and maintain proper levels of engine oil, coolant, brake fluid, power steering fluid, and differential fluid. Contaminated or low fluids can severely damage critical systems. For more detailed insights on fluid checks, you might find our article on Essential Truck Maintenance Checks helpful. (Internal Link Placeholder)

Common Mistakes to Avoid When Dealing with Truck Parts

Understanding what not to do is just as important as knowing what to do. Here are some common pitfalls:

- Ignoring Warning Lights: That "Check Engine" light isn’t just a suggestion; it’s a critical alert. Ignoring it can lead to minor issues becoming major, expensive repairs.

- Using Incorrect Fluids: Not all engine oils or coolants are the same. Using the wrong type can cause serious damage to your engine or transmission. Always refer to your owner’s manual.

- Skipping Preventative Maintenance: Cutting corners on scheduled maintenance to save a few dollars now will almost certainly lead to much larger expenses down the road. Preventative care is an investment, not an expense.

- DIY Repairs Without Knowledge: While some basic tasks are manageable, complex repairs involving critical parts of a truck vehicle should be left to certified mechanics. Improper repairs can compromise safety and vehicle integrity.

- Overloading Your Truck: Exceeding the truck’s Gross Vehicle Weight Rating (GVWR) puts undue stress on the chassis, suspension, tires, brakes, and drivetrain, accelerating wear and increasing the risk of failure. You can find more information on safe loading practices from trusted sources like the Federal Motor Carrier Safety Administration (FMCSA) (External Link Placeholder).

The Future of Truck Parts: Innovation and Technology

The world of truck components is constantly evolving, driven by demands for greater efficiency, safety, and reduced environmental impact. We are witnessing exciting advancements that will redefine how trucks operate.

Electrification is rapidly gaining traction, with electric motors and battery packs replacing traditional internal combustion engines and fuel systems. Advanced Driver-Assistance Systems (ADAS) are becoming standard, incorporating sophisticated sensors, cameras, and ECUs to provide features like adaptive cruise control, lane-keeping assist, and automatic emergency braking, making trucks safer than ever. Telematics and predictive maintenance systems use real-time data from various truck parts to anticipate failures, allowing for proactive repairs and minimizing downtime. This technological shift promises a future of smarter, cleaner, and more reliable trucking.

Conclusion: Empowering Your Journey with Knowledge

Navigating the world of trucks, whether as an owner, operator, or enthusiast, is a journey best undertaken with knowledge. By delving into the intricate parts of a truck vehicle, we’ve uncovered the complex interplay of systems that enable these machines to perform their vital roles. From the roaring engine to the robust chassis, each component is a testament to precision engineering and crucial for the truck’s overall function.

Remember, understanding these truck components isn’t just about technical specifications; it’s about making smarter choices that impact safety, efficiency, and longevity. By embracing regular maintenance, using quality parts, and staying informed about new technologies, you’re not just maintaining a vehicle – you’re safeguarding an investment and ensuring the smooth continuation of commerce and daily life. Keep learning, stay proactive, and your truck will continue to be a reliable partner on the road for years to come.