Unveiling the Anatomy of Durability: Your Ultimate Guide to Truck Body Parts for Longevity & Performance

Unveiling the Anatomy of Durability: Your Ultimate Guide to Truck Body Parts for Longevity & Performance Typestruck.Guidemechanic.com

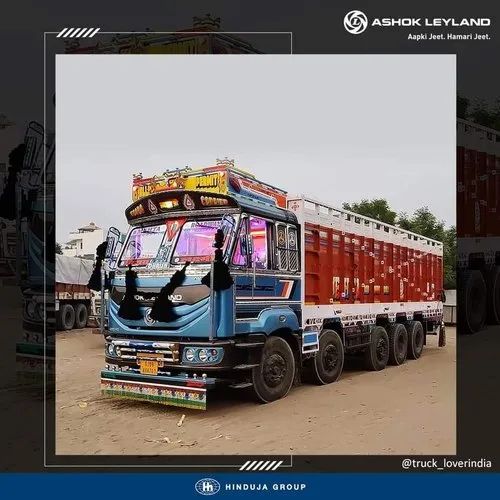

Every day, countless trucks traverse highways and backroads, serving as the backbone of commerce and industry. From hauling goods across continents to navigating rugged construction sites, these workhorses endure immense stress. What often goes unnoticed, yet plays a critical role in their performance, safety, and aesthetic appeal, are the myriad of truck body parts that comprise their robust exterior.

This isn’t just about shiny paint and impressive chrome; it’s about structural integrity, aerodynamic efficiency, and the protection of precious cargo and human lives. As an expert blogger and professional SEO content writer with extensive experience in the automotive sector, I understand the profound importance of each component. This comprehensive guide will delve deep into the world of truck body parts, providing invaluable insights for owners, operators, and enthusiasts alike. We’ll explore their functions, materials, maintenance, and how making informed choices can significantly impact your truck’s lifespan and operational efficiency.

Unveiling the Anatomy of Durability: Your Ultimate Guide to Truck Body Parts for Longevity & Performance

The Foundation: Why Truck Body Parts Matter Beyond Aesthetics

When you think about a truck, the engine and transmission often come to mind first, and rightly so, as they power the vehicle. However, the body of the truck is far more than just a shell; it’s an intricate system of components designed for specific purposes. These truck body parts are fundamental to the vehicle’s overall performance, safety, and even its economic viability.

Beyond merely making your rig look good, they provide crucial protection. They shield vital internal components from the elements, road debris, and potential impacts. This protection extends to the driver and any passengers, forming a critical safety cage in the event of a collision.

From an operational standpoint, the design and condition of these parts directly influence aerodynamics, which in turn affects fuel efficiency – a significant consideration for any fleet or owner-operator. Furthermore, well-maintained and structurally sound body parts contribute significantly to a truck’s resale value, reflecting a commitment to quality and upkeep. Based on my experience, neglecting the condition of your truck’s exterior can lead to a cascade of problems, from accelerated rust to compromised safety features, ultimately costing far more in the long run.

Decoding the Anatomy: Essential Truck Body Parts Explained

To truly appreciate the complexity and engineering behind these vehicles, it’s essential to understand the individual roles of various truck body parts. Each component, no matter how small, contributes to the truck’s overall functionality and resilience. Let’s break down the major sections and their key components.

The Front End: Leading the Charge

The front end of a truck is its most exposed area, constantly facing wind resistance, debris, and potential impacts. It houses several critical components that are vital for both safety and performance.

-

The Hood: More than just a cover, the hood provides aerodynamic shaping and protects the engine bay from environmental elements like rain, dust, and road salt. Modern truck hoods are often designed with lightweight materials such as fiberglass, aluminum, or composite plastics to reduce overall vehicle weight and improve fuel economy. They also play a role in dissipating heat from the engine.

- Pro tips from us: Regularly check hood hinges and latches for proper function. A loose hood can be a serious safety hazard on the road.

-

The Grille: Situated prominently at the front, the grille’s primary function is to allow airflow to the radiator and engine, preventing overheating. Beyond its cooling role, the grille is a significant aesthetic feature, often incorporating the manufacturer’s emblem and defining the truck’s brand identity. It also acts as a primary line of defense against larger debris impacting the radiator.

- The design of the grille can vary significantly between models and manufacturers, influencing both appearance and airflow efficiency.

-

The Bumper: The bumper is a critical safety component, designed to absorb and distribute the force of low-speed impacts, protecting the frame and other vital front-end components. Truck bumpers are typically robust, often made from steel, chrome-plated steel, or heavy-duty composites, built to withstand significant force. They are also vital for mounting lighting and tow hooks.

- Common mistakes to avoid are neglecting bumper damage, as even minor dents can compromise its structural integrity in future collisions.

-

Fenders: Located over the wheels, fenders prevent mud, rocks, and water from being flung up by the tires, protecting the truck’s body, windshield, and other vehicles. They are crucial for maintaining visibility and keeping the truck cleaner. Fenders also house side marker lights and sometimes provide access to internal components like wiring or engine bay accessories.

- Depending on the truck type, fenders can be integrated into the body or be separate, bolt-on units. Materials range from steel to fiberglass.

The Cab & Doors: Your Command Center & Entry Points

The cab is where the driver operates, and its structural integrity is paramount for occupant safety and comfort. Doors provide access and contribute significantly to the cab’s overall strength.

-

Cab Structure: The cab is the protective shell around the driver and passengers. It’s engineered to be a rigid safety cell, designed to withstand impacts and provide maximum occupant protection. This involves high-strength steel frames, reinforced pillars, and strategically placed crumple zones. The structural components of the cab are some of the most complex truck body parts.

- Beyond safety, the cab also houses the dashboard, seating, and controls, making ergonomics and space planning crucial.

-

Doors: Truck doors are not just entry and exit points; they are integral to the cab’s structural integrity. They consist of outer door panels, inner reinforcement beams, window mechanisms, hinges, and latches. Heavy-duty truck doors are built to be robust, often heavier than those on passenger vehicles, reflecting their greater operational demands.

- Pro tips from us: Regularly lubricate door hinges and check the condition of weather stripping to prevent drafts and water leaks.

-

Mirrors: Side mirrors are indispensable safety features, providing the driver with crucial visibility of blind spots and surrounding traffic. Modern trucks often feature large, multi-pane, heated, and electronically adjustable mirrors, sometimes even with integrated cameras for enhanced safety. These are often mounted on robust arms designed to minimize vibration.

- Ensuring your mirrors are properly adjusted and free from damage is a simple yet vital safety check before every journey.

The Side & Rear: Protecting Cargo & Defining the Profile

The side and rear sections of a truck are critical for cargo containment, accessibility, and overall structural support. These truck body parts vary greatly depending on the truck’s specific purpose.

-

Side Panels & Quarter Panels: These large body sections run along the sides of the truck, connecting the front and rear. They contribute significantly to the truck’s overall rigidity and aesthetic flow. In conventional trucks, quarter panels are typically found over the rear wheels, forming part of the cargo box or fender well structure. They are often vulnerable to scrapes and dents.

- Their condition impacts the truck’s appearance and can be indicative of overall maintenance.

-

Truck Bed/Cargo Box: For pickup trucks, the bed is the primary cargo-carrying area. It’s designed to be durable, often featuring reinforced floors and sides to withstand heavy loads and abrasive materials. Materials can include steel, aluminum, or composite liners for added protection. For commercial trucks, this translates to various trailer types, flatbeds, or specialized cargo boxes.

- Based on my experience, a well-maintained truck bed prevents cargo shifting and prolongs the life of the vehicle by preventing rust from trapped moisture.

-

Tailgate: On pickup trucks, the tailgate provides access to the truck bed and can serve as an extension of the bed floor when lowered. It’s a heavy-duty component, often reinforced to handle significant weight. For larger commercial trucks, the "tailgate" concept might translate to rear doors or loading ramps.

- Proper functioning hinges and latches are essential for safety and security when transporting goods.

Lighting & Accessories: Visibility and Compliance

Beyond the main structural components, various lighting and accessory truck body parts are crucial for safety, visibility, and legal compliance.

-

Headlights: Essential for night driving and low-visibility conditions, headlights illuminate the road ahead. Modern trucks utilize various technologies, including halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode) systems, each offering different levels of brightness and energy efficiency. They are legally mandated and critical for safe operation.

- Pro tips from us: Keep headlight lenses clean and clear. Oxidized or foggy lenses can significantly reduce light output.

-

Taillights & Brake Lights: Located at the rear, taillights ensure the truck is visible to following vehicles, especially in the dark. Brake lights illuminate brighter when the brakes are applied, signaling deceleration. These are critical safety features, preventing rear-end collisions. Many trucks also integrate turn signals into the taillight assemblies.

- For current safety regulations concerning vehicle lighting, you can always consult official resources like the National Highway Traffic Safety Administration (NHTSA) website .

-

Marker Lights & Fog Lights: Marker lights (or clearance lights) are crucial for large trucks, indicating the vehicle’s full length and width, particularly at night or in adverse weather. Fog lights, mounted lower on the front bumper, provide a wide, low beam that cuts through fog and heavy rain, improving forward visibility without reflecting glare back to the driver.

- These seemingly minor components play a significant role in overall road safety.

OEM vs. Aftermarket vs. Used: Making the Right Choice

When it comes to replacing or upgrading truck body parts, you’re generally faced with three main options: Original Equipment Manufacturer (OEM), aftermarket, and used/salvaged parts. Each comes with its own set of advantages and disadvantages. Making an informed decision requires balancing cost, quality, fit, and availability.

-

OEM (Original Equipment Manufacturer) Parts:

- Pros: These are identical to the parts your truck came with from the factory. They guarantee a perfect fit, match, and often come with a manufacturer’s warranty. Quality control is typically very high, ensuring durability and performance.

- Cons: They are almost always the most expensive option. Availability can sometimes be an issue for older or less common truck models.

- When to choose: Ideal for critical safety components, major structural parts, or when maintaining original factory specifications and warranty.

-

Aftermarket Parts:

- Pros: Aftermarket parts are produced by companies other than the original truck manufacturer. They are generally more affordable than OEM parts, often significantly so. You’ll find a vast selection, offering various price points, materials, and even performance or aesthetic enhancements not available from the OEM.

- Cons: Quality can vary dramatically. While some aftermarket brands produce excellent components that meet or exceed OEM standards, others may offer inferior products with poor fitment or lower durability. Warranties can also differ.

- Common mistakes to avoid are choosing the cheapest aftermarket option without researching the brand’s reputation or checking reviews. Always prioritize parts from reputable manufacturers.

-

Used/Salvaged Parts:

- Pros: Sourced from wrecked or dismantled trucks, used parts are often the most budget-friendly option. If you find a part from a low-mileage or lightly damaged vehicle, you might get an OEM-quality component at a fraction of the new price. They are also an excellent choice for restoring vintage trucks, where new parts are no longer manufactured.

- Cons: Their history is often unknown. They may have hidden damage, wear, or rust not immediately visible. There’s usually no warranty, and finding the exact match for color or specific trim can be challenging.

- When to choose: Best for non-critical, easily replaceable cosmetic parts, or when budget is extremely tight and you can thoroughly inspect the part beforehand.

Based on my experience, for major structural truck body parts or safety-critical components like bumpers and cab panels, investing in OEM or high-quality aftermarket parts is usually the wiser choice. For less critical items like fenders or minor trim pieces, reputable aftermarket or carefully vetted used parts can be cost-effective.

Maintenance & Longevity: Extending the Life of Your Truck Body Parts

The lifespan and appearance of your truck’s body parts are not solely dependent on their initial quality; diligent maintenance plays a colossal role. Proactive care can prevent premature wear, corrosion, and costly repairs down the line.

-

Regular Inspections: Make it a habit to visually inspect your truck’s exterior regularly. Look for early signs of rust, especially around seams, welds, and areas prone to stone chips. Check for loose fasteners on fenders, bumpers, and mirrors. Examine lights for cracks or moisture intrusion. Early detection of issues can prevent them from escalating into major problems.

- Pro tips from us: Pay close attention to the undercarriage and wheel wells, as these areas are constantly exposed to road grime and moisture, making them prime targets for rust.

-

Cleaning & Protection: Regular washing removes dirt, salt, and other corrosive contaminants. After washing, consider applying a good quality wax or sealant to painted surfaces. This creates a protective barrier against UV rays, which can fade paint and degrade plastic components, and further repels water and dirt. For the undercarriage, an annual undercoating or rust inhibitor application can significantly extend the life of metal components.

- Protecting your truck’s finish isn’t just about aesthetics; it’s about preserving the underlying metal from corrosion.

-

Collision Repair Considerations: Even minor fender benders can have hidden consequences. If your truck has been involved in a collision, ensure that all damaged truck body parts are professionally repaired or replaced. A shoddy repair can lead to misalignment, water leaks, and accelerated rust due to compromised paint and sealant. It’s not just about fixing what’s visible.

- Based on my experience, a common mistake is underestimating the damage from seemingly minor impacts. Always get a professional assessment.

-

Addressing Specific Issues:

- Rust: Treat any rust spots immediately. Sand down the affected area, apply a rust converter, primer, and touch-up paint. For larger areas, professional bodywork might be necessary.

- Dents & Scratches: Small dents can sometimes be pulled out using specialized tools. Scratches, depending on their depth, can be polished out or require touch-up paint. Addressing these promptly prevents moisture from penetrating the paint and starting the rust process.

- UV Damage: Sun exposure can fade paint and make plastic components brittle. Parking in the shade or using a truck cover can help, as can UV-protective waxes and dressings for plastics.

Sourcing & Installation: What You Need to Know

Once you’ve identified the need for a new or replacement truck body part, the next steps involve sourcing it and arranging for installation. This process can be straightforward or complex, depending on the part and your skill level.

-

Where to Buy:

- Dealerships: Offer OEM parts with guaranteed fit and warranty, but at a premium price.

- Independent Parts Stores: Provide a mix of OEM and aftermarket options, often with knowledgeable staff.

- Online Retailers: Offer vast selections of both OEM and aftermarket parts, often at competitive prices. Be sure to check return policies and customer reviews.

- Salvage Yards/Auto Recyclers: Best for used parts, providing a cost-effective solution, especially for older models.

- For more detailed insights on choosing the right supplier, check out our guide on .

-

Key Considerations When Buying:

- VIN Compatibility: Always provide your truck’s Vehicle Identification Number (VIN) to ensure you get the exact part compatible with your specific make, model, and year.

- Warranty: Understand the warranty offered on the part, whether it’s OEM or aftermarket.

- Return Policy: Familiarize yourself with the seller’s return policy, especially for online purchases, in case of incorrect fitment or damage.

- Reviews: For aftermarket parts, always check reviews from other truck owners to gauge quality and fitment.

-

Installation: DIY vs. Professional:

- DIY: Some truck body parts, like mirrors, headlight assemblies, or certain fender flares, can be replaced by a mechanically inclined individual with basic tools. This can save on labor costs.

- Professional: For complex structural components, paint matching, or parts requiring specialized tools and expertise (e.g., cab panels, major bumper replacements, collision repair), professional installation is highly recommended. Improper installation can lead to safety hazards, poor fitment, and further damage.

- If you’re considering a full truck restoration, our guide on offers valuable insights into managing such projects.

Conclusion: Investing in Your Rig’s Future

The world of truck body parts is far more intricate and vital than a cursory glance might suggest. From the structural integrity of the cab to the aerodynamic contours of the hood, each component plays an indispensable role in ensuring your truck’s safety, performance, and longevity. Understanding these parts, their functions, and how to properly maintain and source them is not just about keeping your truck looking good; it’s about making a sound investment in its operational efficiency and overall lifespan.

By prioritizing quality, performing regular inspections, and addressing issues promptly, you can significantly extend the life of your valuable asset. Remember, your truck is more than just a vehicle; it’s a tool for livelihood and a testament to hard work. Investing in its well-being, starting with its robust exterior, ensures it remains a reliable partner for countless miles to come. Drive safely, maintain diligently, and choose wisely – your rig will thank you for it.