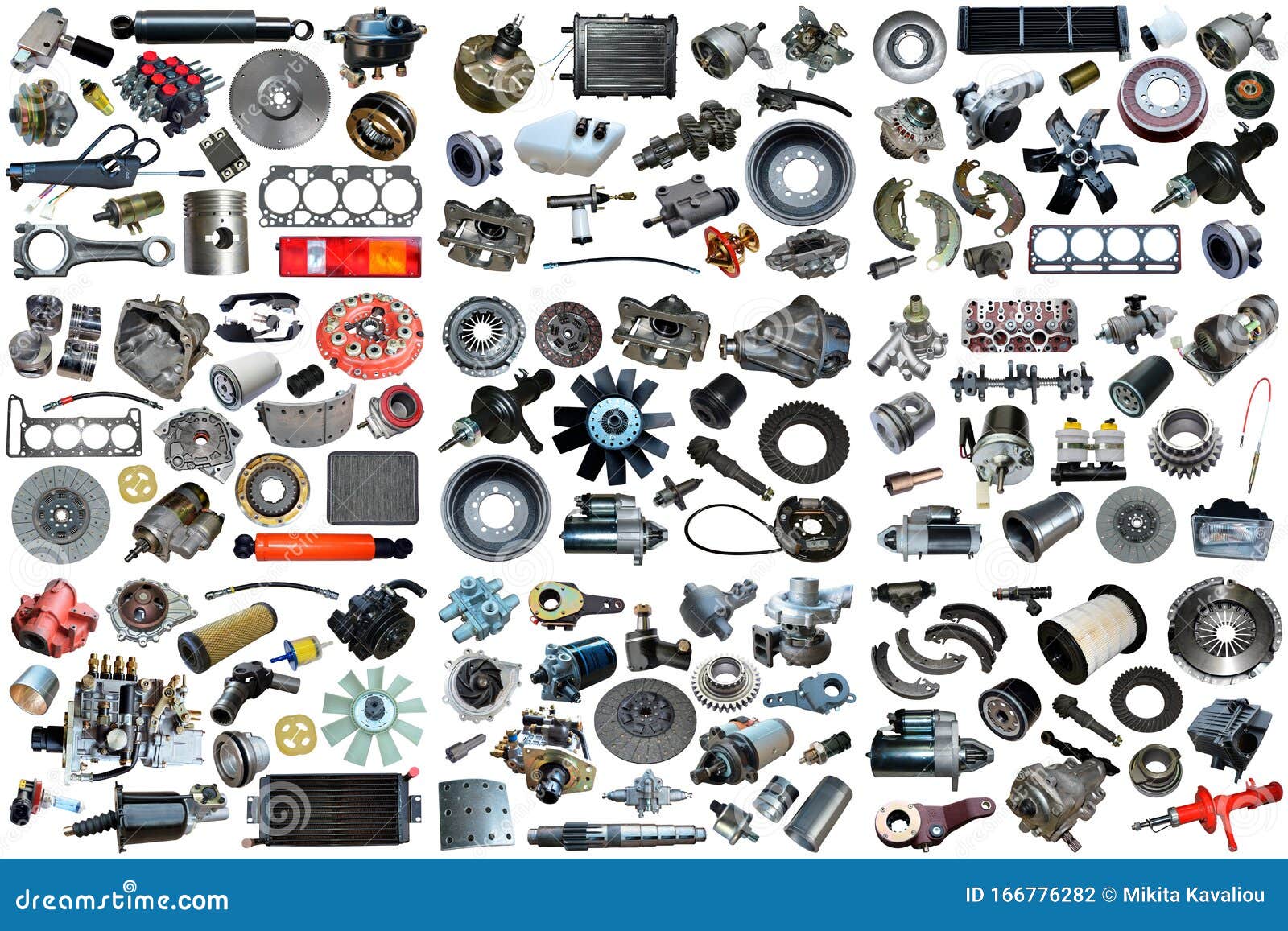

Unveiling the Anatomy of a Beast: A Deep Dive into the Essential Parts of a Truck

Unveiling the Anatomy of a Beast: A Deep Dive into the Essential Parts of a Truck Typestruck.Guidemechanic.com

Trucks are the undisputed workhorses of our modern world. From delivering everyday goods to hauling massive loads across continents, these mechanical titans are indispensable. But what exactly makes these complex machines tick? Understanding the parts of a truck isn’t just for mechanics; it’s crucial for owners, operators, and anyone who relies on them.

This comprehensive guide will take you on an in-depth journey through the intricate anatomy of a truck. We’ll explore everything from the fundamental structure to the sophisticated systems that ensure power, safety, and efficiency. Our goal is to provide you with pillar content that not only educates but also empowers you with the knowledge to appreciate, maintain, and troubleshoot these incredible vehicles.

Unveiling the Anatomy of a Beast: A Deep Dive into the Essential Parts of a Truck

The Unseen Hero: The Chassis and Frame – The Truck’s Backbone

Every truck, regardless of its size or purpose, starts with a robust foundation: the chassis and frame. Think of this as the skeleton upon which all other components are built. It’s the primary load-bearing structure, designed to withstand immense stress and strain.

What is the Chassis and Frame?

The frame typically consists of two long, parallel beams (often called frame rails) connected by cross-members. This ladder-like structure provides the rigid support needed for the engine, transmission, axles, suspension, and body. It’s engineered to distribute weight evenly and absorb impacts, protecting the crucial internal systems.

Why is it So Important?

Based on my experience, the integrity of the chassis is paramount. Any compromise here – be it from corrosion, cracks, or damage – can severely impact the truck’s stability, handling, and overall safety. It’s the unsung hero that ensures the truck remains structurally sound, whether it’s navigating rough terrain or cruising at highway speeds. Regular inspections for rust and damage are critical.

The Heartbeat of the Machine: The Engine System

If the chassis is the skeleton, the engine is undeniably the heart. It’s the power plant that converts fuel into mechanical energy, driving the entire vehicle. For most heavy-duty trucks, we’re talking about powerful diesel engines, renowned for their torque and fuel efficiency over long distances.

Key Components of the Engine System:

The engine is a marvel of engineering, comprising hundreds of interconnected parts. Here are some of the most critical:

- Cylinder Block: This forms the main structure of the engine, housing the cylinders where combustion occurs. It’s usually made from cast iron or aluminum, built for durability.

- Pistons: These cylindrical components move up and down within the cylinders, driven by the expanding gases from combustion. They are connected to the crankshaft.

- Crankshaft: This rotating shaft converts the linear motion of the pistons into rotational motion. It’s the primary output shaft of the engine, sending power to the transmission.

- Cylinder Head: Sitting atop the cylinder block, the cylinder head contains the intake and exhaust valves, and often the fuel injectors for diesel engines. It seals the combustion chambers.

- Valves: Precisely timed valves (intake and exhaust) control the flow of air into and exhaust gases out of the cylinders. They are actuated by the camshaft.

- Fuel System: For diesel engines, this includes the fuel tank, fuel pump, fuel filters, and high-pressure fuel injectors. This system delivers a precise amount of atomized fuel into the combustion chambers.

- Cooling System: Engines generate immense heat. The cooling system, comprising the radiator, water pump, thermostat, and coolant, dissipates this heat to prevent overheating and maintain optimal operating temperature.

- Lubrication System: The oil pump circulates engine oil throughout the engine, reducing friction, cooling components, and cleaning internal parts. The oil pan holds the oil reservoir.

- Exhaust System: After combustion, exhaust gases are expelled through the exhaust manifold, turbocharger (if present), particulate filters (DPF), selective catalytic reduction (SCR) systems, and muffler, before exiting into the atmosphere. Modern truck exhaust systems are complex, designed to reduce emissions significantly.

Pro Tips from Us: Engine maintenance is non-negotiable. Regular oil changes, filter replacements (fuel, oil, air), and coolant checks are vital for engine longevity and performance. Ignoring these can lead to costly breakdowns.

Harnessing the Power: The Drivetrain System

The drivetrain is responsible for transmitting the power generated by the engine to the wheels, ultimately moving the truck forward. It’s a complex chain of components, each playing a crucial role in managing speed and torque.

The Transmission:

This is the gearbox that allows the driver to select different gear ratios, matching engine speed to road speed and load requirements.

- Manual Transmissions: Common in heavy trucks, these require the driver to manually shift gears using a clutch pedal and gear stick. They offer greater control and often better fuel efficiency for experienced drivers.

- Automatic Transmissions: Increasingly popular, these systems automatically select the appropriate gear, reducing driver fatigue and simplifying operation.

- Automated Manual Transmissions (AMTs): A hybrid, AMTs use an electronically controlled clutch and shifting mechanism, offering the efficiency of a manual with the convenience of an automatic.

The Driveshaft (Propeller Shaft):

The driveshaft is a long, rotating tube that connects the transmission’s output shaft to the differential. It’s designed to transmit torque over varying distances and angles, often using universal joints (U-joints) to accommodate movement.

The Differential:

Located on the axle, the differential is a clever gear assembly that allows the drive wheels to rotate at different speeds. This is crucial when turning, as the outer wheel needs to travel a greater distance than the inner wheel. Without a differential, the wheels would skid, especially in turns, causing tire wear and control issues.

Axles:

Axles are shafts that connect the wheels to the differential and support the weight of the truck.

- Drive Axles: These are the axles that receive power from the differential and turn the wheels. Heavy trucks often have multiple drive axles (tandem axles) for increased traction and load-carrying capacity.

- Steer Axles: The front axle, which is responsible for steering the truck.

- Trailer Axles: For semi-trailers, these axles are non-driven but support the trailer’s load.

The Lifesaver: The Braking System

No matter how powerful a truck is, its ability to stop safely is paramount. The braking system is one of the most critical safety features, designed to slow down or halt the vehicle under various conditions. Heavy trucks primarily use air brake systems, known for their reliability and power.

Components of an Air Brake System:

- Air Compressor: Driven by the engine, this component generates compressed air and stores it in reservoirs (air tanks).

- Air Tanks (Reservoirs): These sturdy tanks store compressed air for the braking system.

- Brake Lines and Hoses: A network of lines and hoses carries compressed air from the tanks to the brake chambers.

- Brake Chambers: These components convert the air pressure into mechanical force. When air enters the chamber, a diaphragm pushes a rod, which in turn actuates the brakes.

- Slack Adjusters: These automatically or manually adjust the distance between the brake chamber pushrod and the S-cam, ensuring proper brake shoe-to-drum clearance.

- S-Cam: This S-shaped cam rotates when activated by the slack adjuster, forcing the brake shoes outward against the brake drum.

- Brake Shoes and Linings: These friction materials are pressed against the brake drum, creating friction that slows the wheel.

- Brake Drums (or Rotors for Disc Brakes): The rotating component that the brake shoes/pads press against.

Advanced Braking Technologies:

- Anti-lock Braking System (ABS): This electronic system prevents the wheels from locking up during hard braking, allowing the driver to maintain steering control.

- Engine Brakes (Jake Brakes) / Retarders: These supplementary braking systems use the engine’s compression or other mechanisms to slow the truck, reducing wear on the service brakes, especially on long descents.

Common Mistakes to Avoid Are: Neglecting daily pre-trip brake inspections. Checking air pressure, listening for air leaks, and ensuring slack adjusters are within limits are vital for safe operation.

Smooth Ride and Precise Control: Suspension and Steering Systems

For a truck to be drivable, it needs systems that absorb road imperfections and allow the driver to accurately guide the vehicle. This is where the suspension and steering systems come into play.

The Suspension System:

The suspension system acts as a buffer between the wheels and the chassis, absorbing shocks and vibrations from the road. It enhances ride comfort, maintains tire contact with the road, and helps stabilize the vehicle.

- Leaf Springs: Traditional and robust, these consist of layers of curved steel leaves bolted together. They are common in heavy-duty applications due to their load-carrying capacity.

- Air Springs (Air Bags): Increasingly popular, air springs use compressed air to support the load. They offer a smoother ride, adjustable ride height, and better load equalization, which is particularly beneficial for sensitive cargo.

- Shock Absorbers: These hydraulic or gas-filled cylinders dampen the oscillations of the springs, preventing excessive bouncing and improving stability.

The Steering System:

The steering system allows the driver to control the direction of the truck. It’s designed for precision and responsiveness, crucial for navigating traffic and maneuvering large vehicles.

- Steering Wheel: The driver’s primary input device.

- Steering Column: Connects the steering wheel to the steering gearbox.

- Steering Gearbox: Converts the rotational motion of the steering column into linear motion, which is then transmitted to the wheels.

- Drag Link and Tie Rods: These components connect the steering gearbox to the steering knuckles, allowing the wheels to turn.

- Power Steering Pump: Provides hydraulic assistance, making it much easier for the driver to turn the heavy wheels of a truck.

The Electrical Nervous System: Powering the Modern Truck

Modern trucks are highly sophisticated machines, heavily reliant on a complex electrical system. This network powers everything from starting the engine to running advanced safety features and infotainment systems.

Key Electrical Components:

- Battery: Stores electrical energy, primarily used to start the engine and power accessories when the engine is off. Trucks often have multiple heavy-duty batteries.

- Alternator: Once the engine is running, the alternator generates electricity to power the truck’s electrical systems and recharge the battery.

- Starter Motor: A powerful electric motor that turns the engine’s crankshaft to initiate combustion.

- Wiring Harness: A bundled assembly of electrical wires, connectors, and terminals that transmit power and signals throughout the truck.

- Fuses and Relays: Fuses protect circuits from overcurrent, while relays are electrically operated switches that control high-current devices with a low-current signal.

- Lighting System: Includes headlights, tail lights, brake lights, turn signals, marker lights, and interior lights – all critical for visibility and safety.

- Electronic Control Units (ECUs) / Engine Control Modules (ECMs): These onboard computers manage various engine functions, transmission shifts, braking systems, and more. They monitor sensors and make real-time adjustments for optimal performance and efficiency.

- Sensors and Actuators: Sensors gather data (e.g., temperature, pressure, speed) and send it to the ECUs, while actuators are devices that perform an action based on ECU commands (e.g., opening fuel injectors, adjusting turbo boost).

Based on my experience: Electrical issues can be notoriously difficult to diagnose. Regular checks of battery terminals, wiring integrity, and fuse boxes can prevent many common problems.

The Driver’s Command Center: The Cabin and Interior

While often overlooked in terms of "parts," the cabin is where the driver spends countless hours. Its design and components are critical for driver comfort, safety, and operational efficiency.

Inside the Cabin:

- Seats: Ergonomically designed seats with air suspension are common to reduce driver fatigue on long hauls.

- Dashboard and Gauges: Provides vital information about the truck’s operation, including speed, engine RPM, oil pressure, coolant temperature, and air pressure for the braking system.

- Controls: Steering wheel, pedals (accelerator, brake, clutch), gear selector, and numerous switches for lights, wipers, HVAC, and auxiliary equipment.

- HVAC System: Heating, Ventilation, and Air Conditioning system ensures a comfortable cabin temperature, crucial for driver well-being in all climates.

- Safety Features: Seatbelts are mandatory, and some modern trucks may include advanced driver-assistance systems (ADAS) like lane departure warnings, collision mitigation systems, and even airbags.

- Sleeper Cab: For long-haul trucks, the sleeper cab provides living space, including a bed, storage, and sometimes a small refrigerator or microwave, allowing drivers to rest on the road.

Making Contact: Wheels and Tires

The wheels and tires are the only parts of the truck that actually touch the road. Their condition directly impacts traction, handling, fuel efficiency, and safety.

Wheel Components:

- Rims: The metal part of the wheel that the tire is mounted on. Truck rims are typically made of steel for durability or aluminum for weight savings and aesthetics.

- Hubs: Connect the wheel to the axle, allowing it to rotate.

- Lug Nuts: Secure the wheel to the hub. Proper torque is essential.

Tire Types and Importance:

- Steer Tires: Designed for precise steering and stability, typically with straight grooves.

- Drive Tires: Feature aggressive tread patterns for maximum traction to propel the truck.

- Trailer Tires: Designed for free-rolling and load carrying, often with shallower treads.

- Tire Pressure Monitoring Systems (TPMS): Increasingly common, these systems alert the driver to low tire pressure, preventing blowouts and improving fuel economy.

Pro Tips from Us: Maintaining correct tire pressure is one of the easiest ways to improve fuel efficiency and extend tire life. Regularly check tread depth and inspect for uneven wear, which can indicate suspension or alignment issues.

Essential Support Systems

Beyond the major systems, several other components play vital roles in a truck’s operation.

- Fuel Tank: Stores the diesel fuel required for the engine. Truck fuel tanks are often very large to accommodate long travel distances.

- Mirrors: Critical for visibility, especially for blind spots around a large truck. Many modern trucks use multiple mirrors or camera systems.

- Wipers and Washer System: Ensure clear visibility through the windshield in adverse weather conditions.

- Horns: Essential safety devices for signaling other road users. Trucks typically have both electric and air horns.

Pro Tips for Truck Owners and Operators: Mastering Your Machine

Understanding the individual parts of a truck is a significant step, but knowing how to manage them collectively is where true expertise lies. Here are some actionable insights:

- Embrace the Owner’s Manual: This document is a treasure trove of information specific to your truck model. It details maintenance schedules, fluid specifications, warning light meanings, and much more.

- Stick to a Strict Maintenance Schedule: Preventative maintenance is far cheaper and safer than reactive repairs. Adhere to manufacturer-recommended intervals for oil changes, filter replacements, fluid checks, and component inspections.

- Prioritize Quality Replacement Parts: When a component needs replacing, always opt for high-quality, reputable parts. While aftermarket options can be cheaper, compromising on quality can lead to premature failure and more expensive repairs down the line. Based on my experience, using OEM (Original Equipment Manufacturer) or equivalent quality parts significantly extends component life.

- Master Pre-Trip Inspections: Before every journey, conduct a thorough pre-trip inspection. This includes checking tires, lights, brakes, fluid levels, and looking for any visible damage or leaks. This simple routine can prevent major breakdowns and ensure compliance with safety regulations. You can find comprehensive guides on pre-trip inspections from trusted sources like the Federal Motor Carrier Safety Administration (FMCSA).

- Listen to Your Truck: Pay attention to unusual noises, vibrations, smells, or changes in performance. A slight change in engine sound or a new vibration could be an early warning sign of a developing problem. Don’t ignore dashboard warning lights.

- Invest in Training: For drivers, continuous training on new technologies, defensive driving, and proper truck operation is invaluable. For mechanics, staying updated on diagnostic tools and repair techniques for modern truck systems is crucial. For a deeper dive into common truck issues and diagnostics, check out our article on Troubleshooting Common Truck Problems.

Conclusion: The Symphony of Steel and Power

The sheer number and complexity of the parts of a truck are astounding. From the robust chassis that forms its foundation to the sophisticated electronic systems that manage its every function, each component plays a critical role in the truck’s overall performance, reliability, and most importantly, safety.

By understanding the anatomy of these incredible machines, you gain a deeper appreciation for the engineering marvels they represent. More importantly, this knowledge empowers you to make informed decisions regarding maintenance, operation, and troubleshooting. Whether you’re a truck owner, operator, or simply someone interested in the mechanics of these road giants, recognizing the symphony of steel and power that makes a truck move is the first step towards ensuring its longevity and efficiency. Keep learning, keep inspecting, and keep those wheels rolling safely! For further reading on truck maintenance best practices, explore our related content on Maximizing Truck Lifespan Through Preventative Care.