Unleashing Performance: A Deep Dive into Fiberglass Race Truck Bodies for Ultimate Speed and Durability

Unleashing Performance: A Deep Dive into Fiberglass Race Truck Bodies for Ultimate Speed and Durability Typestruck.Guidemechanic.com

In the exhilarating world of motorsports, every ounce matters, and every aerodynamic curve counts. Race truck bodies are no exception. While traditional metal bodies have their place, the racing community increasingly turns to advanced materials to gain a competitive edge. This is where fiberglass race truck bodies emerge as a game-changer, offering a powerful blend of lightweight performance, impressive durability, and aesthetic flexibility.

As an expert who has spent years immersed in the intricacies of race vehicle construction, I’ve witnessed firsthand the transformative impact fiberglass has had on the track. This comprehensive guide will take you deep into the world of these specialized bodies, exploring their benefits, construction, installation, and maintenance. Our goal is to provide you with invaluable insights, helping you understand why fiberglass is not just a trend, but a fundamental evolution in race truck design.

Unleashing Performance: A Deep Dive into Fiberglass Race Truck Bodies for Ultimate Speed and Durability

The Unrivaled Advantages: Why Fiberglass Dominates Race Truck Construction

When building a high-performance race truck, decisions about body materials are paramount. Fiberglass offers a compelling suite of advantages that directly translate to better performance, increased safety, and long-term cost efficiency. These benefits are precisely why it has become the material of choice for serious competitors.

1. Superior Lightweight Performance: The Need for Speed

The most significant advantage of fiberglass race truck bodies is their inherent lightness. Fiberglass composites are considerably lighter than steel or aluminum, often reducing the overall vehicle weight by hundreds of pounds. This substantial weight reduction directly impacts critical performance metrics.

A lighter truck accelerates faster, carries more speed through corners, and places less strain on the braking system. It also improves the power-to-weight ratio, a key determinant of a race vehicle’s overall performance. Based on my experience, shedding unnecessary weight is often the most cost-effective way to find extra speed on the track.

2. Unmatched Aerodynamic Flexibility: Sculpting for Speed

Fiberglass is a highly moldable material, allowing manufacturers to create complex and optimized aerodynamic shapes that would be incredibly difficult and expensive to achieve with metal. This flexibility is crucial for designing custom race truck bodies that slice through the air with minimal drag.

From sleek front fascias to sculpted fenders and integrated spoilers, fiberglass enables designs that enhance downforce, improve airflow around the vehicle, and reduce turbulence. Every subtle curve and vent can be precisely engineered to give the truck a significant advantage in terms of straight-line speed and stability at high speeds.

3. Impressive Durability and Impact Resistance: Built for Battle

Despite being lightweight, fiberglass boasts remarkable strength and impact resistance. Unlike metal, which can dent and crease permanently, fiberglass can absorb impacts and flex, often returning to its original shape or sustaining localized, repairable damage. This is particularly vital in the rough-and-tumble environment of truck racing.

Fiberglass composites are engineered to withstand the stresses of high-speed racing, including minor collisions and vibrations. This inherent durability means less downtime for repairs after incidents, keeping your truck on the track and in contention.

4. Excellent Corrosion Resistance: A Longer Lifespan

Another often-overlooked benefit is fiberglass’s complete immunity to rust and corrosion. Unlike steel bodies that require constant vigilance against moisture and oxidation, fiberglass remains unaffected by environmental elements. This ensures the structural integrity and aesthetic appeal of your racing fiberglass panels over many seasons.

This resistance to corrosion contributes significantly to the longevity of the body. You won’t find rust bubbles forming under the paint, which translates to less maintenance and a better-looking truck throughout its competitive life.

5. Ease of Repair: Getting Back in the Race Faster

Should damage occur, fiberglass is remarkably forgiving to repair. Small cracks or punctures can often be fixed relatively quickly and cost-effectively using specialized repair kits, resins, and fiberglass cloth. This is a stark contrast to metal bodywork, which often requires specialized welding, panel beating, or complete panel replacement.

Pro tips from us: Learning basic fiberglass repair techniques can save you significant time and money during a race weekend. Many teams keep a small repair kit on hand for quick fixes between heats or races.

Understanding the Construction: What Makes Fiberglass Race Truck Bodies Tick?

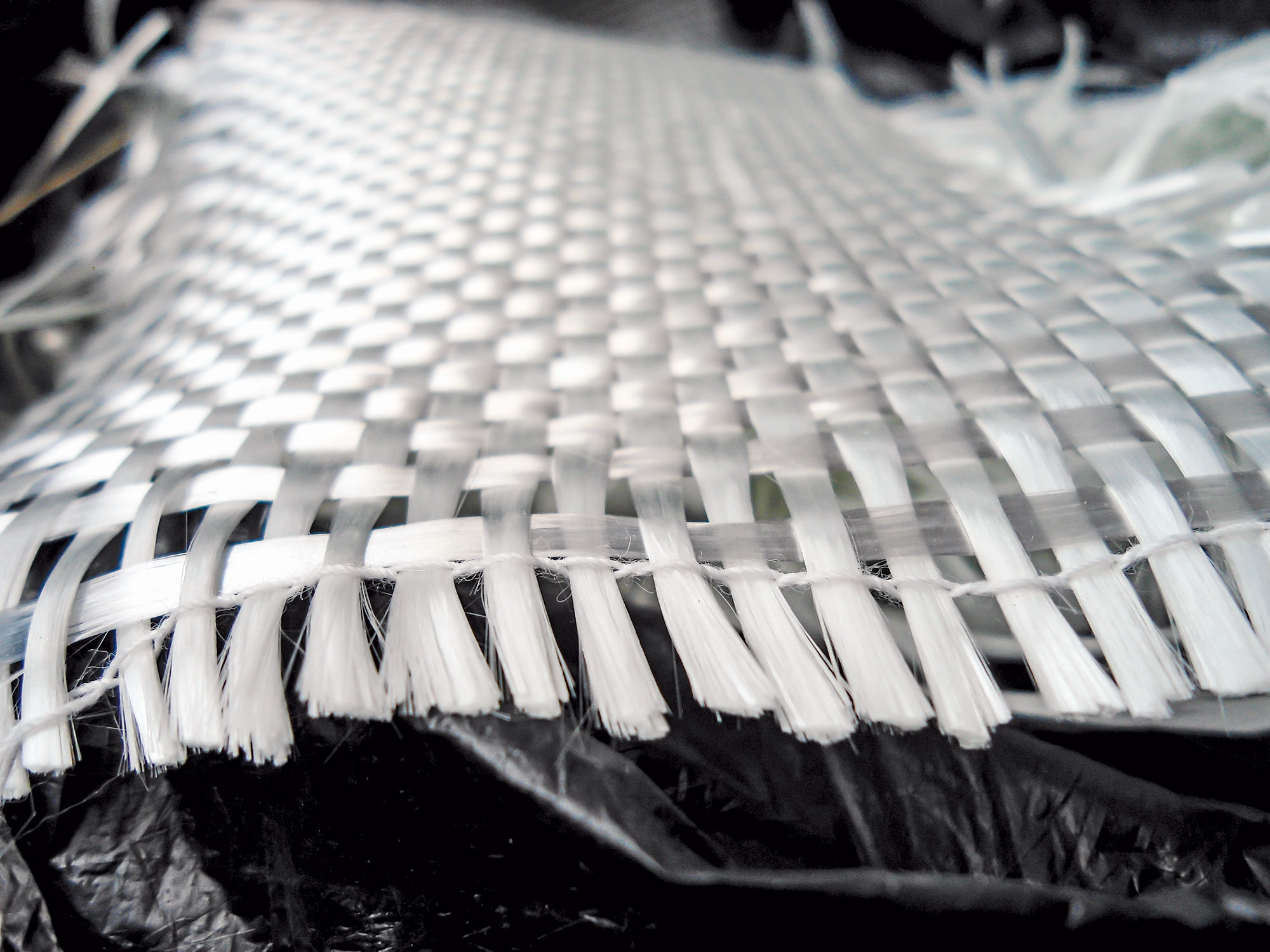

The strength and versatility of fiberglass come from its composite nature. It’s not a single material but a combination of glass fibers embedded within a resin matrix. Understanding this fundamental construction helps appreciate the engineering behind these lightweight marvels.

1. Key Materials: The Building Blocks of Strength

- Glass Fibers: These are the primary reinforcement material, providing tensile strength and stiffness. They come in various forms, including woven mats, chopped strand mats, and rovings, each offering different properties.

- Resins: The resin binds the glass fibers together, forming a solid, rigid structure. Common resins used in fiberglass composite construction include:

- Polyester Resin: Economical and widely used for many fiberglass applications.

- Vinyl Ester Resin: Offers superior strength, flexibility, and chemical resistance compared to polyester, making it popular for high-stress racing components.

- Epoxy Resin: Provides the highest strength, stiffness, and adhesion, often used in aerospace and high-performance racing applications where cost is less of a concern.

2. Manufacturing Processes: Crafting the Shell

Several methods are used to produce racing fiberglass panels, each with its advantages:

- Hand Lay-up: This traditional method involves manually laying fiberglass mats into a mold and saturating them with resin using brushes and rollers. It’s labor-intensive but allows for complex shapes and custom one-off parts.

- Spray-up: Similar to hand lay-up but uses a chopper gun to simultaneously spray chopped glass fibers and resin into the mold. It’s faster for larger, less intricate parts.

- Vacuum Infusion: This advanced process involves placing dry fiberglass and core materials into a mold, sealing it with a vacuum bag, and then drawing resin into the mold using vacuum pressure. This method results in a very high fiber-to-resin ratio, leading to lighter, stronger, and more consistent parts with fewer air bubbles. Many high-quality lightweight truck bodies are made using this method.

3. Strategic Reinforcement: Strength Without the Weight Penalty

To further enhance strength and stiffness without adding excessive weight, manufacturers often incorporate core materials between layers of fiberglass. These include:

- Foam Cores (e.g., PVC foam, urethane foam): These lightweight cores provide bulk and rigidity, creating a sandwich panel effect that significantly increases stiffness-to-weight ratio.

- Balsa Wood Cores: Balsa is surprisingly strong for its weight and is often used in marine and some automotive composite applications for its excellent strength and impact absorption.

The careful selection of materials and manufacturing processes ensures that each fiberglass race truck body panel delivers optimal performance, durability, and weight savings for competitive racing.

Types of Fiberglass Race Truck Bodies: Tailoring Your Build

The term "fiberglass race truck body" encompasses a range of products, from complete conversions to individual panels. Understanding the different types helps in planning your build or upgrade strategy.

1. Full Body Kits: A Complete Transformation

Full body kits typically replace the entire exterior shell of a production truck, from the front bumper to the rear bed. These kits are designed for maximum weight savings and aerodynamic optimization. They often include:

- Front fenders and hood

- Cab roof and rear cab sections

- Doors (or door skins)

- Bed sides and tailgate (or a complete bed assembly)

- Front and rear bumpers/valances

Opting for a full body kit provides the most dramatic weight reduction and allows for a truly custom, race-specific aesthetic. It’s ideal for ground-up builds or major overhauls.

2. Individual Panels: Targeted Upgrades

For those not ready for a full body conversion, individual racing fiberglass panels offer a modular approach to performance enhancement. Common individual fiberglass components include:

- Fiberglass Hoods: Often featuring scoops or vents for engine cooling and improved aerodynamics.

- Fiberglass Fenders: Wider and lighter than stock, accommodating larger tires and reducing unsprung weight.

- Fiberglass Bed Sides: Lightweight replacements for heavy steel beds, particularly beneficial for rear weight distribution.

- Fiberglass Cab Caps/Roofs: Reduces high-up weight, lowering the truck’s center of gravity.

These individual panels allow teams to incrementally upgrade their trucks, targeting specific areas for weight reduction or aerodynamic improvements while potentially retaining other stock components.

3. Custom vs. Off-the-Shelf: Precision or Practicality

- Off-the-Shelf Bodies: These are pre-designed and manufactured lightweight truck bodies that fit popular truck chassis models. They offer a balance of performance and accessibility, often being more readily available and less expensive than fully custom options. They’re a great starting point for many racing classes.

- Custom Race Truck Bodies: Tailored to specific chassis dimensions, aerodynamic requirements, or unique aesthetic visions. Custom bodies involve significant design and tooling costs but offer unparalleled optimization for a particular racing application. This route is typically reserved for professional teams or high-budget builds seeking every possible advantage.

Installation Insights: Getting Your Fiberglass Race Truck Body Right

Proper installation is just as crucial as the quality of the fiberglass itself. A poorly fitted body can hinder aerodynamics, create vibrations, and even compromise safety. Based on my experience, attention to detail during this phase is paramount for optimal performance and longevity.

1. Meticulous Preparation: The Foundation of Success

Before installing any new fiberglass race truck bodies, thorough preparation is essential. This involves:

- Stripping the Old Body: Carefully remove all existing body panels, paying attention to hidden fasteners and electrical connections. Documenting this process can be helpful for reassembly.

- Chassis Inspection: With the old body removed, inspect the chassis for any damage, cracks, or rust. This is the ideal time to make any necessary repairs or modifications to the frame. Ensure the chassis is clean and free of debris where new panels will attach.

- Test Fitting: Before any permanent fastening, dry-fit all new fiberglass panels. This allows you to identify any fitment issues, trim excess material, or adjust mounting points before commitment.

2. Mounting Techniques: Secure and Accessible

The way racing fiberglass panels are attached can significantly impact their durability and ease of maintenance. Common mounting techniques include:

- Brackets and Tabs: Fabricated metal brackets are often used to secure larger panels to the chassis. These should be robust, well-reinforced, and designed to distribute loads evenly.

- Dzus Fasteners: These quick-release fasteners are a staple in motorsports. They allow for rapid removal and reinstallation of panels, which is critical for trackside adjustments and maintenance. Ensure Dzus tabs are properly aligned and reinforced to prevent tear-out from the fiberglass.

- Adhesives: High-strength structural adhesives can be used in conjunction with mechanical fasteners or in areas where a seamless bond is desired. These adhesives provide excellent shear strength and can help dampen vibrations.

Pro tips from us: Always use anti-seize compound on threaded fasteners and Dzus springs to prevent galling and ensure easy removal, especially in high-heat or high-vibration environments.

3. Alignment and Fitment: Precision for Performance

Achieving perfect alignment isn’t just about aesthetics; it’s critical for aerodynamics and structural integrity.

- Panel Gaps: Strive for consistent, minimal panel gaps. Large or uneven gaps can create turbulent airflow, increasing drag and reducing speed.

- Body Lines: Ensure that the body lines flow smoothly from one panel to the next. This indicates proper alignment and contributes to a clean aerodynamic profile.

- Clearance: Verify adequate clearance between the fiberglass body and tires, suspension components, and exhaust. This prevents rubbing, which can damage the body and hinder performance, particularly during suspension travel.

Common mistakes to avoid are rushing the installation, neglecting to reinforce mounting points, and not thoroughly checking clearances. These shortcuts can lead to costly damage or performance issues down the road.

Maintenance & Longevity: Keeping Your Fiberglass Flawless

Proper care and maintenance will significantly extend the life and preserve the appearance of your fiberglass race truck bodies. Regular inspections and timely repairs are key to maximizing your investment.

1. Cleaning: Protect and Preserve

- Gentle Washing: Use mild automotive soap and soft sponges or microfiber cloths. Avoid harsh detergents or abrasive materials that can scratch the gel coat or painted surface.

- Waxing/Sealing: Regularly apply a high-quality automotive wax or sealant. This creates a protective barrier against UV rays, dirt, and minor abrasions, keeping the finish vibrant and easier to clean.

2. Inspection for Damage: Catching Issues Early

After every race or practice session, conduct a thorough inspection of your racing fiberglass panels:

- Look for Cracks: Pay close attention to areas around mounting points, stress points (e.g., wheel wells, door openings), and corners. Even small hairline cracks can propagate if left unaddressed.

- Check for Delamination: Inspect for any signs where fiberglass layers might be separating, indicated by bubbling or soft spots.

- Examine Mounting Points: Ensure all fasteners are secure and that the fiberglass around them isn’t showing signs of stress or fatigue.

3. Repairing Minor Damage: DIY or Pro?

Minor cracks, chips, or gouges in fiberglass can often be repaired with a basic fiberglass repair kit.

- DIY Repairs: For small, non-structural damage, you can sand the area, apply new resin and fiberglass mat, and then sand smooth and paint. This is an essential skill for any race team.

- Professional Repairs: For extensive damage, structural repairs, or if you lack confidence, seek a professional fiberglass repair shop. They have the expertise and specialized tools to ensure a strong, seamless repair.

4. Painting & Finishing: More Than Just Looks

A good paint job not only makes your truck look great but also adds a layer of protection to the fiberglass.

- Proper Preparation: Ensure the fiberglass surface is thoroughly cleaned, sanded, and primed before painting for optimal adhesion and a smooth finish.

- Quality Paints: Use durable automotive paints designed to withstand the harsh racing environment, including impacts and UV exposure.

Fiberglass vs. Traditional Metal: A Head-to-Head Comparison

While metal bodies have a long history in racing, fiberglass offers distinct advantages that are difficult for traditional materials to match in high-performance applications.

| Feature | Fiberglass Race Truck Bodies | Traditional Metal (Steel/Aluminum) |

|---|---|---|

| Weight | Significantly lighter; major advantage for speed and handling. | Heavier, impacting acceleration, braking, and tire wear. |

| Strength | High strength-to-weight ratio; good impact absorption. | Steel is very strong; aluminum is lighter but often less impact resistant. |

| Repairability | Relatively easy to repair localized damage with kits and resin. | Often requires specialized welding, panel beating, or full panel replacement. |

| Aerodynamics | Highly moldable for complex, optimized aerodynamic shapes. | Limited by manufacturing processes; more costly to achieve complex curves. |

| Corrosion | Completely rust and corrosion-proof. | Prone to rust (steel) or oxidation (aluminum), requiring protective coatings. |

| Cost (Initial) | Can be comparable or slightly higher than metal for custom pieces. | Can be lower for standard panels, but custom fabrication is expensive. |

| Cost (Long-term) | Lower repair costs, longer lifespan due to corrosion resistance. | Higher repair costs, potential for rust issues. |

Safety Considerations with Fiberglass Bodies: Built for Protection

Safety is always paramount in motorsports. While fiberglass race truck bodies are lightweight, they are also designed with safety in mind.

- Impact Absorption: Fiberglass can be engineered to absorb and dissipate impact energy, potentially reducing the force transmitted to the driver in a crash.

- Roll Cage Integration: Fiberglass bodies are typically designed to fit over a robust internal roll cage, which provides the primary occupant protection. The body itself is a shell, while the cage is the structural safety component. Always ensure your fiberglass body provides adequate clearance for your SFI-certified roll cage.

- Fire Retardant Options: For certain racing categories, fire-retardant resins or coatings can be specified for fiberglass components, adding an extra layer of safety. Always refer to official racing regulations for specific requirements. You can learn more about motorsports safety standards from trusted sources like External Link: SFI Foundation (motorsports safety standards).

Choosing the Right Manufacturer/Supplier: Quality Matters

Selecting a reputable manufacturer for your fiberglass race truck bodies is critical to ensure you receive a high-quality product that meets your performance and safety expectations.

- Reputation and Experience: Look for manufacturers with a proven track record in motorsports. Check reviews, testimonials, and see what professional teams use their products.

- Quality of Materials and Manufacturing: Inquire about the types of resins and fiberglass used, and their manufacturing processes (e.g., hand lay-up, vacuum infusion). Higher quality materials and processes generally yield stronger, lighter, and more durable parts.

- Fitment and Finish: Ask for examples of their work or detailed photos. Good fitment and a smooth finish indicate a commitment to quality.

- Customization Options: If you need specific modifications or a completely custom body, ensure the manufacturer has the capabilities and experience to deliver.

- Customer Support: A good manufacturer will offer excellent pre-sales advice and post-sales support, including installation guidance and troubleshooting.

The Future of Race Truck Bodies: Innovation Continues

The evolution of race truck bodies doesn’t stop with fiberglass. The motorsports industry is constantly pushing boundaries, exploring even more advanced materials and manufacturing techniques. We’re seeing increasing research into:

- Advanced Composites: Beyond traditional fiberglass, materials like carbon fiber and aramid fibers (Kevlar) are being integrated into hybrid composites to create even lighter and stronger structures. While more expensive, these offer unparalleled performance for top-tier racing.

- Additive Manufacturing (3D Printing): While not yet mainstream for full body panels, 3D printing is being used for molds, prototypes, and intricate aerodynamic components, potentially revolutionizing custom part creation.

- Sustainability: As environmental concerns grow, manufacturers are exploring more sustainable resins and recycled composite materials, aiming to reduce the ecological footprint of motorsports.

These innovations promise an even more exciting future for lightweight truck bodies in racing, continuously pushing the limits of speed and efficiency.

Conclusion: Embrace the Power of Fiberglass for Your Race Truck

The choice of body material is a cornerstone of race truck performance. As we’ve explored, fiberglass race truck bodies offer an undeniable competitive advantage through significant weight reduction, superior aerodynamic flexibility, impressive durability, and straightforward repairability. They are a smart investment for any serious competitor looking to gain an edge on the track.

From the raw materials to the meticulous installation process, every aspect of fiberglass construction is geared towards maximizing speed, enhancing handling, and ensuring longevity. By understanding these intricacies, you can make informed decisions that will directly impact your success. So, whether you’re building a new contender or upgrading an existing machine, consider the profound benefits of fiberglass. It’s more than just a body; it’s a strategic component designed to unleash your truck’s ultimate performance.