Unleash Your Truck’s Full Potential: The Ultimate Guide to Truck Flatbed DIY Plans Free

Unleash Your Truck’s Full Potential: The Ultimate Guide to Truck Flatbed DIY Plans Free Typestruck.Guidemechanic.com

Have you ever looked at your pickup truck and wished it offered more versatility, more hauling capacity, or just a more rugged, utilitarian aesthetic? For many truck owners, the standard bed, while practical, can feel limiting. This is where the allure of a flatbed comes in, transforming your truck into a true workhorse capable of handling oversized loads, specialized equipment, or even serving as a robust base for overland adventures.

The idea of converting your truck to a flatbed might seem daunting, conjuring images of complex fabrication and hefty professional bills. However, what if we told you that with the right guidance, some dedication, and access to Truck Flatbed DIY Plans Free, you could tackle this project yourself? This comprehensive guide is designed to empower you with the knowledge, tips, and insights needed to embark on your own DIY truck flatbed build, saving money, gaining invaluable skills, and creating a truly custom rig.

Unleash Your Truck’s Full Potential: The Ultimate Guide to Truck Flatbed DIY Plans Free

Why Go DIY? The Unbeatable Benefits of Building Your Own Flatbed

Embarking on a DIY project, especially one as significant as a flatbed conversion, brings a unique blend of challenges and rewards. The primary motivation for many is the substantial cost savings compared to purchasing a pre-made flatbed or having one custom-built by a shop. You control the budget, sourcing materials that fit your financial plan.

Beyond the financial aspect, building your own flatbed offers unparalleled customization. You aren’t limited by off-the-shelf designs; instead, you can tailor every dimension, every storage compartment, and every mounting point to perfectly suit your specific needs and the type of work or recreation you envision. This level of personalized functionality is something mass-produced units simply cannot match.

Furthermore, there’s an immense sense of satisfaction and pride that comes from building something with your own hands. It’s a learning experience that hones your fabrication skills, problem-solving abilities, and mechanical aptitude. The durability and quality can often exceed commercial options, especially when built with careful attention to detail and robust materials.

Before You Begin: Essential Preparations & Critical Considerations

Before you even think about grabbing a wrench or firing up a welder, thorough preparation is paramount. This isn’t just about gathering tools; it’s about understanding the landscape of your project, from legalities to personal capabilities. Skipping these initial steps can lead to costly mistakes, safety hazards, or even legal repercussions.

First and foremost, legal and safety considerations must be at the forefront of your planning. Every state and local jurisdiction has specific regulations regarding vehicle modifications, dimensions, lighting, and load securement. You must investigate these thoroughly. Always refer to the latest guidelines from official sources like the National Highway Traffic Safety Administration (NHTSA) for vehicle safety standards, and check your local Department of Motor Vehicles (DMV) for state-specific rules.

Understanding your truck’s Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Ratings (GAWR) is critical. Your new flatbed, plus any cargo, must not exceed these manufacturer-specified limits. Overloading is not only dangerous but also illegal. Additionally, consider the implications for your vehicle insurance; inform your provider about significant modifications to ensure continued coverage.

Assessing your skills is another crucial step. Building a robust and safe flatbed typically requires proficiency in welding, metal fabrication, basic automotive mechanics, and electrical wiring. If you’re new to these, consider taking a local welding class or enlisting the help of experienced friends. There’s no shame in seeking assistance for tasks that are beyond your current skill set.

Budgeting is more than just material costs. Factor in consumables like welding wire, grinding discs, cutting wheels, safety gear, and paint. Don’t forget potential costs for specialized tools you might need to rent or buy. Pro tips from us: Always add a 15-20% contingency to your budget for unexpected expenses.

Finally, choosing your truck for the conversion is vital. Not all trucks are ideal candidates. Look for a solid frame with minimal rust. Consider the truck’s intended use; a heavy-duty truck will be better suited for a robust flatbed than a lighter-duty pickup. Extensive research into existing flatbed designs will also provide inspiration and help you refine your vision.

Finding Your "Free" Foundation: Sourcing DIY Flatbed Plans

The beauty of the internet is the vast ocean of shared knowledge, and finding Truck Flatbed DIY Plans Free is certainly possible if you know where to look. These resources can provide a fantastic starting point, offering designs, dimensions, and even step-by-step instructions that you can adapt to your specific truck and needs.

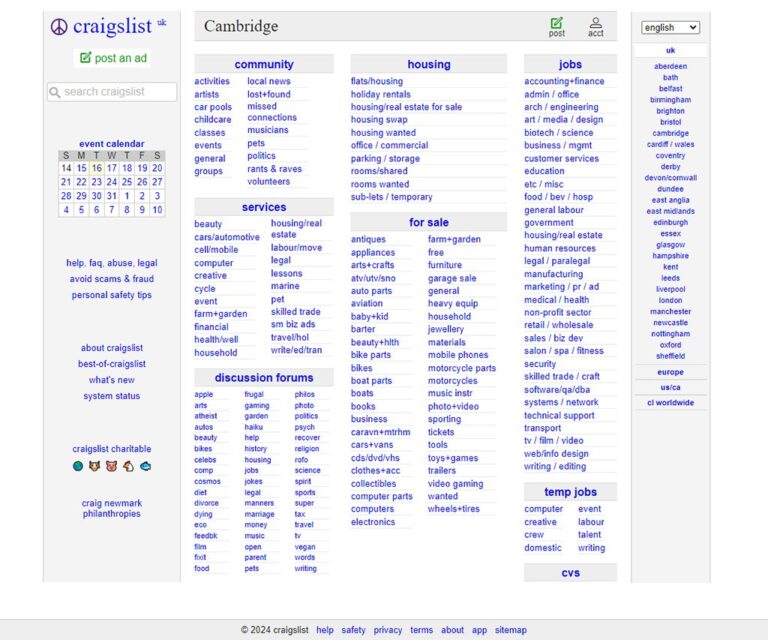

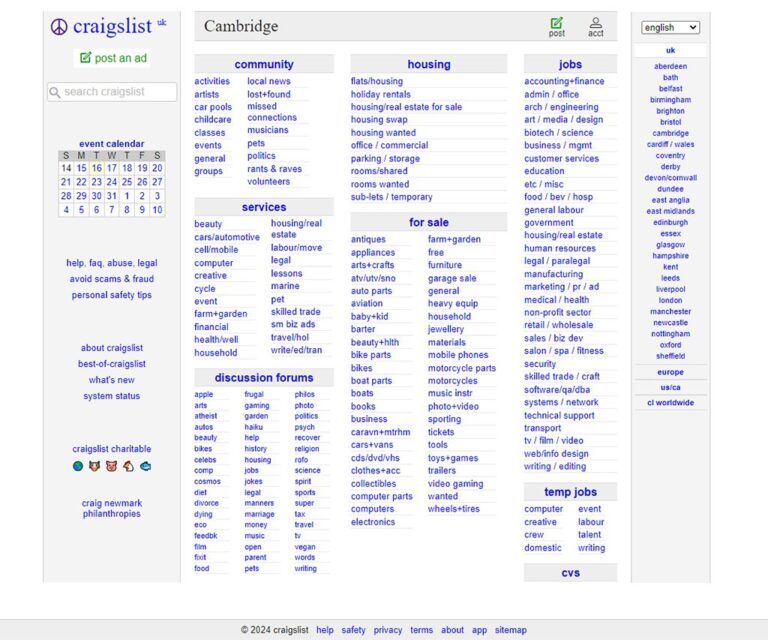

Online communities and forums dedicated to truck enthusiasts, off-roading, and fabrication are goldmines. Websites like Pirate4x4, welding forums, or even general automotive DIY communities often have threads where members share their build logs, schematics, and advice. Engaging with these communities can provide invaluable insights and peer support.

YouTube tutorials offer a visual learning experience that static plans often can’t replicate. Many skilled fabricators document their entire build process, showing cuts, welds, and mounting techniques in detail. Watching several different builds can help you understand various approaches and identify common challenges.

While less common for full flatbed designs, some open-source CAD files or basic blueprints might be shared on specialized engineering or fabrication sites. These often require CAD software to view, but they can offer precise dimensions and material lists. Public libraries and old manuals can also be surprisingly useful; older fabrication textbooks or even agricultural equipment manuals sometimes contain basic design principles applicable to flatbeds.

Common mistakes to avoid are assuming that "free" means "perfectly suited" or "no effort required." Free plans are starting points, not rigid blueprints. You will almost certainly need to adapt dimensions, material choices, and mounting methods to fit your specific truck model and local regulations. Always scrutinize the quality and safety recommendations of any free plan you find.

Key Design Elements of a Robust DIY Flatbed

A well-designed flatbed isn’t just a flat surface; it’s a carefully engineered structure that integrates seamlessly with your truck’s chassis, providing strength, safety, and functionality. Understanding its core components is essential for a successful build.

The frame or subframe is the backbone of your flatbed. It’s the structure that directly mounts to your truck’s chassis. Typically constructed from heavy-duty steel channel, tubing, or angle iron, its design dictates the overall strength and load-bearing capacity. The method of mounting to the truck frame is critical; bolt-on designs allow for easier removal and less permanent modification, while weld-on designs offer maximum rigidity but are permanent. Based on my experience, a robust subframe with adequate crossmembers is paramount for preventing twisting and ensuring even load distribution.

Decking material options range from steel plate to wood or composite materials. Steel diamond plate offers superior durability and a non-slip surface but adds significant weight. Treated lumber or marine-grade plywood provides a lighter, more affordable option but may require more frequent maintenance. Composites offer a balance of durability and lighter weight but can be more expensive. Consider your primary use and budget when making this choice.

A headache rack is a non-negotiable safety feature. Mounted at the front of the flatbed, behind the cab, it protects occupants from shifting cargo during sudden stops or accidents. It can also provide a sturdy mounting point for auxiliary lights, antennas, or tool storage. Don’t underestimate its importance.

Side rails and a tailgate are optional but highly recommended for most applications. Removable or folding side rails enhance load security, preventing items from sliding off. A sturdy tailgate, also often removable, provides additional load containment and can double as a ramp support or work surface. These features significantly increase the versatility of your flatbed.

Lighting and wiring are not just functional but a legal necessity. Your flatbed must replicate all original truck lighting functions: tail lights, brake lights, turn signals, and often marker lights if the flatbed extends beyond the original truck’s width. Proper wiring, using weatherproof connectors and conduits, is essential for reliability and safety. Common mistakes to avoid are neglecting proper grounding or using inadequate wire gauges, which can lead to electrical failures.

Finally, consider integrated toolboxes and storage. A custom flatbed offers the perfect opportunity to incorporate built-in storage solutions beneath the deck or within the headache rack. This keeps tools, chains, and straps secure and easily accessible, greatly enhancing the utility of your truck.

Step-by-Step Guide: The Flatbed Construction Process (General Overview)

While specific steps will vary based on your chosen Truck Flatbed DIY Plans Free and your truck model, here’s a generalized overview of the construction process. This sequence emphasizes safety, precision, and a logical progression of tasks.

Step 1: Removal of the Old Bed. This is where your project officially begins. Carefully disconnect all wiring, fuel filler neck, and mounting bolts securing the factory bed. It’s often helpful to have a few extra hands or a hoist for safe removal. Preserve any components you might reuse, such as the fuel filler or wiring harness.

Step 2: Frame Preparation. With the old bed removed, meticulously clean the exposed truck chassis. Inspect for any rust, damage, or fatigued areas. Address any rust with wire brushing, rust converter, and primer. Ensure the frame rails are straight and level, as this forms the foundation for your new flatbed.

Step 3: Subframe Fabrication & Mounting. This is arguably the most critical stage. Based on your plans, cut and assemble the main subframe components. Precision in measurement and cutting is paramount here. Test fit the subframe to the truck chassis, ensuring it sits level and clears all obstacles. Once satisfied, securely mount it using your chosen method – whether bolting through the frame with high-grade hardware or carefully welding it in place. Pro tip: Measure thrice, cut once, especially when dealing with structural components.

Step 4: Decking Installation. With the subframe firmly in place, it’s time to install your chosen decking material. Whether it’s steel plate, wood planks, or composite, ensure it’s cut to the correct dimensions and securely fastened to the subframe. If using wood, pre-drill holes to prevent splitting and use corrosion-resistant fasteners.

Step 5: Headache Rack & Side Rails. Fabricate and attach your headache rack, ensuring it’s robustly mounted to the flatbed subframe. If you’re incorporating side rails or a tailgate, now is the time to build and install their mounting points and mechanisms. Test their operation to ensure smooth movement and secure locking.

Step 6: Wiring & Lighting. This step requires careful attention to detail. Route all necessary wiring for tail lights, brake lights, turn signals, and any additional marker lights or auxiliary lighting. Use appropriate gauge wire, solder connections where possible, and protect all wiring with conduit or loom. Install your chosen light fixtures and thoroughly test all electrical functions before proceeding.

Step 7: Finishing Touches. Once the main structure is complete and all systems are working, focus on protection and aesthetics. Sand any rough edges, grind down sharp corners, and apply a high-quality primer and paint system to all steel components. This prevents rust and provides a professional finish. Install any toolboxes, tie-down points, or other accessories.

Step 8: Final Inspection & Testing. Before hitting the road, conduct a thorough inspection of every weld, bolt, and connection. Safely perform a load test with a representative weight to ensure structural integrity. Finally, take your truck for a short, cautious road test to ensure everything feels secure and functions correctly.

Essential Tools and Materials You’ll Need

Having the right tools and materials on hand will make your DIY flatbed build significantly smoother and safer. Attempting to improvise with inadequate equipment can lead to frustration and compromised results.

Essential Tools:

- Welder: A MIG welder is often preferred for its versatility and ease of use on various metal thicknesses.

- Angle Grinder: Indispensable for cutting, grinding welds, and surface preparation.

- Metal Saw: A chop saw or band saw for precise cuts on steel tubing and channel.

- Drill Press/Hand Drill: For drilling mounting holes.

- Measuring Tools: Tape measure, steel ruler, square, level – precision is key.

- Clamps: A variety of C-clamps, welding clamps, and bar clamps for holding pieces during fabrication.

- Safety Gear: Welding helmet, gloves, safety glasses, ear protection, respirator, fire extinguisher. Common mistake: Underestimating the need for proper safety equipment; never compromise on PPE!

- Jacks & Jack Stands: For safely supporting the truck during bed removal and subframe installation.

- Wire Strippers & Crimpers: For electrical work.

Key Materials:

- Structural Steel: Steel channel (e.g., C-channel), square or rectangular tubing for the subframe and crossmembers.

- Decking Material: Steel diamond plate, treated lumber, or marine-grade plywood.

- Fasteners: High-grade bolts, nuts, washers (grade 8 or equivalent for structural connections).

- Wiring & Lights: Automotive-grade wire, weatherproof connectors, tail lights, brake lights, turn signals, marker lights.

- Paint & Primer: Rust-inhibiting primer and durable topcoat paint.

- Consumables: Welding wire, grinding discs, cutting wheels, sandpaper.

Safety, Legalities, and Common Pitfalls to Avoid

Building a flatbed is a rewarding project, but it carries significant responsibilities. Prioritizing safety and legal compliance is not just about avoiding fines; it’s about protecting yourself, others, and the integrity of your vehicle.

Safety First: Always wear appropriate Personal Protective Equipment (PPE) – welding helmet, gloves, eye protection, ear protection, and appropriate clothing. Ensure your workspace is well-ventilated, especially when welding or painting. Have a fire extinguisher readily accessible. When lifting heavy components, use proper lifting techniques and equipment, never relying solely on human strength. Always work on a stable, level surface, and use jack stands to support your vehicle.

Legal Compliance: As mentioned, vehicle modifications are regulated. Ensure your completed flatbed adheres to all federal, state, and local laws regarding:

- Dimensions: Overall length, width, and height.

- Weight Limits: Do not exceed your truck’s GVWR or GAWR.

- Lighting: All required lights must be present, functional, and visible.

- Load Securement: Ensure you have adequate tie-down points for securing cargo.

- State Inspections: Some states require vehicles with significant modifications to undergo a specialized inspection. Based on my experience, it’s always best to consult your local Department of Motor Vehicles or equivalent agency before you start the build.

Common Pitfalls to Avoid:

- Overloading: This is perhaps the most dangerous mistake. An overloaded flatbed can lead to premature suspension wear, braking issues, tire failure, and catastrophic structural failure. Always know your truck’s limits.

- Poor Welding/Fabrication: Weak welds or incorrectly fabricated components can fail under stress, leading to dangerous situations. If you’re not confident in your welding skills, seek professional help for critical structural welds.

- Inadequate Rust Prevention: Exposed steel will rust. Neglecting proper priming and painting will significantly shorten the lifespan of your flatbed.

- Incorrect Wiring: Faulty wiring can lead to blown fuses, non-functional lights, or even electrical fires. Use correct wire gauges, secure connections, and protect wiring from abrasion and moisture.

- Ignoring Frame Damage: If your truck’s original frame has significant rust or damage, addressing this is paramount before building anything new on top of it.

- Insufficient Tie-Down Points: Without robust and strategically placed tie-down points, securing loads safely becomes impossible, creating a serious hazard.

Maintenance & Longevity: Keeping Your DIY Flatbed in Top Shape

Building your own flatbed is a significant achievement, and proper maintenance will ensure it serves you reliably for years to come. Just like any other part of your truck, it requires ongoing attention.

Regular inspections are crucial. Periodically check all welds for cracks, especially after hauling heavy loads. Examine all bolted connections to ensure they remain tight. Look for any signs of rust developing, particularly in areas where paint might have chipped or scraped.

Address rust promptly by cleaning the area, applying a rust converter, priming, and repainting. This small effort prevents minor surface rust from becoming a major structural issue. Inspect all wiring for fraying, loose connections, or signs of corrosion, especially around light fixtures.

Promptly repair any damage, no matter how minor it seems. A small crack in a weld can propagate, and a loose bolt can lead to excessive wear. By dedicating a little time to routine checks and preventative measures, you can ensure your custom flatbed remains a durable and functional asset for your truck.

Conclusion: Your Custom Flatbed Awaits!

Building your own truck flatbed is more than just a project; it’s an investment in your truck’s capability, your skills, and your independence. With access to Truck Flatbed DIY Plans Free and the comprehensive guidance outlined in this article, you have the foundation to transform your standard pickup into a highly versatile, custom-tailored workhorse or adventure rig.

Remember, success lies in thorough preparation, careful execution, and an unwavering commitment to safety and legal compliance. While challenging, the satisfaction of standing back and admiring a robust, functional flatbed that you built with your own hands is truly unparalleled. So, gather your tools, start your research, and unleash the full potential of your truck today!