The Unsung Heroes: A Deep Dive into USA Truck Terminals and Their Vital Role in American Logistics

The Unsung Heroes: A Deep Dive into USA Truck Terminals and Their Vital Role in American Logistics Typestruck.Guidemechanic.com

In the vast, intricate web of America’s supply chain, certain hubs operate tirelessly, often unseen but always essential. These are the USA truck terminals – the nerve centers that keep goods flowing from coast to coast. Far more than just parking lots for big rigs, these facilities are sophisticated logistics operations, orchestrating the movement of virtually everything we consume, from our morning coffee to the latest electronics.

As an expert blogger and professional SEO content writer with extensive experience in the logistics sector, I’ve witnessed firsthand the incredible complexity and critical importance of these operations. This article aims to be your definitive guide, providing a comprehensive, in-depth look at what makes truck terminals in the USA so indispensable, how they function, and why understanding them is key to appreciating the backbone of our economy.

The Unsung Heroes: A Deep Dive into USA Truck Terminals and Their Vital Role in American Logistics

What Exactly is a USA Truck Terminal? Beyond Just a Parking Lot

When most people picture a "truck terminal," they might imagine a sprawling parking lot filled with semi-trucks. While parking is certainly a component, it’s a gross oversimplification. A USA truck terminal is a specialized facility designed for the efficient handling, storage, maintenance, and distribution of freight transported by trucks. Think of it as a crucial interchange in the national transportation network, where cargo is sorted, transferred, and prepared for its next leg of the journey.

These terminals are the operational heart for trucking companies. They facilitate the complex logistics required to move goods efficiently, acting as consolidation and deconsolidation points. Without them, the seamless flow of goods that underpins modern commerce would grind to a halt.

Pro tips from us: It’s important to distinguish a truck terminal from a truck stop. A truck stop primarily caters to drivers, offering fuel, food, and rest. A truck terminal, on the other hand, is focused on the freight itself and the operational needs of the trucking fleet.

The Multifaceted Roles of Truck Terminals in the USA Supply Chain

The functions of trucking terminals are incredibly diverse, each contributing significantly to the overall efficiency and reliability of the supply chain. They are dynamic ecosystems, buzzing with activity around the clock.

Freight Consolidation and Deconsolidation (Cross-Docking)

One of the primary functions of a USA truck terminal is the consolidation and deconsolidation of freight. This process, often referred to as cross-docking, is a cornerstone of efficient logistics, especially for Less-Than-Truckload (LTL) shipments.

In an LTL scenario, multiple smaller shipments from different senders, all heading in the same general direction, are combined onto a single trailer. This maximizes trailer capacity and reduces transportation costs. Conversely, when a full trailer arrives with various shipments destined for different local receivers, the terminal facilitates the "deconsolidation," breaking down the large load into smaller, manageable deliveries. This meticulous sorting ensures that each package reaches its correct final destination.

Based on my experience, mastering cross-docking is what separates an efficient terminal from a bottleneck. It requires precise timing, ample dock space, and well-trained personnel to quickly move freight from inbound to outbound trailers with minimal storage time.

Warehousing and Temporary Storage

While not primarily long-term storage facilities, truck terminals often include warehousing capabilities for temporary holding of freight. This can be necessary for various reasons: shipments arriving early, loads needing to be held until a delivery window opens, or cargo awaiting further consolidation.

These temporary storage areas are crucial for maintaining flow. They prevent trucks from being idled unnecessarily and ensure that the next stage of the journey can proceed without disruption. Modern terminals often utilize sophisticated inventory management systems to track every item within these temporary storage zones, ensuring accountability and preventing loss.

Vehicle Maintenance and Repair Facilities

A fleet of trucks is a significant investment, and keeping them on the road is paramount. Many large USA truck terminals house dedicated maintenance and repair shops. These facilities are equipped to handle routine preventative maintenance, such as oil changes and tire rotations, as well as more complex repairs.

Having on-site maintenance capabilities minimizes downtime for vehicles, which directly translates to cost savings and improved delivery schedules. It also ensures that trucks meet safety standards and are always in optimal working condition, preventing breakdowns that could cause significant delays and financial losses.

Driver Support and Amenities

While not their primary function, many trucking terminals recognize the importance of supporting their drivers. Long-haul trucking is a demanding profession, and providing amenities can significantly boost driver morale and retention.

These amenities can range from comfortable break rooms, showers, and laundry facilities to secure parking and even training areas. A well-rested and supported driver is a safer and more efficient driver. Providing these resources is an investment in the most valuable asset of any trucking company: its people. You can learn more about what keeps drivers going in our article on Life on the Road: Essential Truck Driver Amenities (Internal Link 1).

Dispatch and Operations Hub

At the core of every USA truck terminal is its dispatch and operations center. This is where the strategic decisions are made, routes are planned, and drivers are assigned to loads. Communication is constant, with dispatchers coordinating with drivers, shippers, and receivers to ensure timely pickups and deliveries.

Modern dispatch centers utilize advanced software to optimize routes, track vehicles in real-time, and manage driver hours of service (HOS) to ensure regulatory compliance. This central command structure is vital for maximizing efficiency and responsiveness across the entire fleet.

Security and Safety Protocols

Given the high value of the cargo passing through them, security is a paramount concern for trucking terminals. These facilities often employ robust security measures, including perimeter fencing, controlled access points, surveillance cameras, and security personnel.

Beyond protecting freight from theft, safety protocols are also crucial for personnel. This includes strict adherence to safety guidelines for loading/unloading, equipment operation, and general site awareness. A secure and safe terminal protects both valuable goods and the people who handle them.

Administrative and Management Offices

Behind the scenes, the administrative and management offices are where the business operations of the terminal are conducted. This includes human resources, accounting, customer service, and strategic planning. These teams ensure that the terminal operates smoothly, complies with regulations, and meets its financial objectives.

The efficiency of these administrative functions directly impacts the overall effectiveness of the terminal. Well-managed paperwork, clear communication, and proactive problem-solving are just as important as the physical movement of freight.

Types of Truck Terminals You’ll Find Across America

The diverse needs of the logistics industry have led to the evolution of several specialized types of USA truck terminals. Each serves a distinct purpose within the broader supply chain.

LTL (Less-Than-Truckload) Terminals

LTL terminals are arguably the most complex and bustling of all. They are designed specifically to handle smaller shipments from multiple customers, consolidating them into full truckloads for line-haul transportation between terminals. Upon arrival at the destination terminal, these consolidated loads are then broken down and delivered to individual receivers.

These terminals typically feature extensive dock space with numerous doors, sophisticated sorting systems, and a vast network of local delivery trucks. They are the backbone of the LTL shipping model, enabling cost-effective transportation for businesses that don’t have enough freight to fill an entire trailer.

FTL (Full Truckload) Terminals

FTL terminals are generally simpler in their operation compared to their LTL counterparts. Their primary function is to stage full truckloads for departure or to receive and park full loads before final delivery. There’s less emphasis on sorting and cross-docking, as the entire trailer is dedicated to a single shipper’s cargo.

These terminals often serve as transfer points for drivers, allowing one driver to drop off a loaded trailer and pick up another, minimizing their downtime. While simpler, they are just as crucial for the high-volume, direct shipments that characterize much of the American economy.

Intermodal Terminals

Intermodal terminals are a critical link in the multi-modal transportation chain. These facilities connect trucking operations with other modes of transport, primarily rail, but also sometimes sea or air. Here, containers or trailers are seamlessly transferred between trucks and trains (or ships/planes).

This allows for the cost-effective long-haul movement of freight by rail, combined with the flexibility of truck delivery for the "first mile" and "last mile." The growth of intermodal shipping has significantly impacted the design and location of these specialized trucking terminals.

Dedicated Fleet Terminals

Some large businesses or specialized carriers operate dedicated fleet terminals. These facilities are exclusively used by a single company or for a specific client’s logistics needs. They are often tailored to handle unique product requirements, such as refrigerated goods or hazardous materials.

Having a dedicated terminal allows for highly customized operations, specialized equipment, and greater control over the supply chain for that particular entity. This is common in industries requiring strict temperature control or specialized handling.

Specialized Terminals

Beyond these general categories, there are also highly specialized USA truck terminals designed for unique cargo. This could include terminals for oversized loads, bulk commodities, or even highly sensitive materials. These facilities often require specific equipment, trained personnel, and strict regulatory compliance tailored to the nature of the goods they handle.

Key Factors Driving the Location and Design of USA Truck Terminals

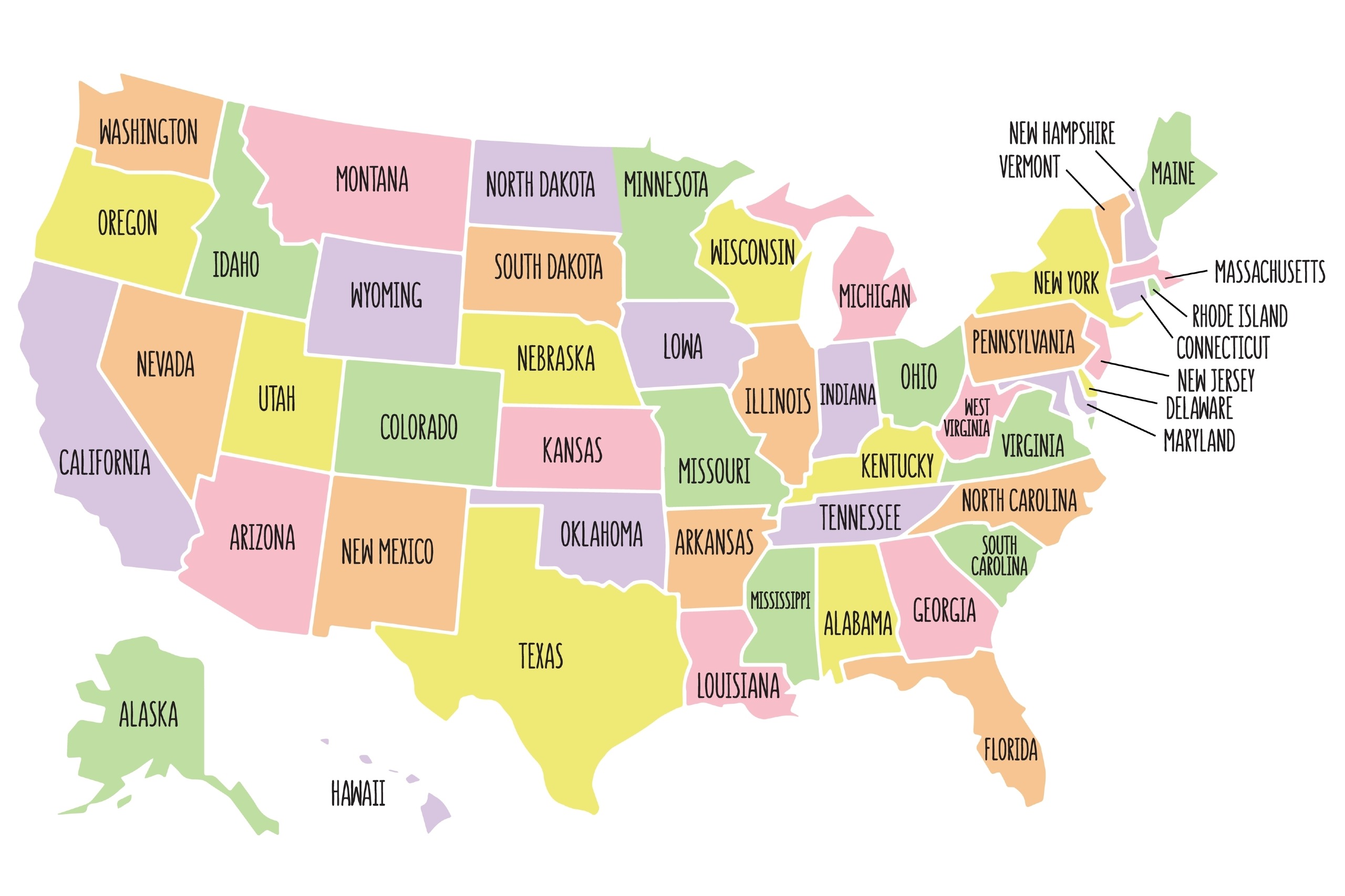

The strategic placement and thoughtful design of truck terminals are not arbitrary; they are the result of careful planning influenced by a multitude of factors. These decisions significantly impact operational efficiency and cost-effectiveness.

Proximity to Major Highways and Interstates

This is perhaps the most critical factor. Terminals must have direct and easy access to major transportation arteries. Locating near interstates minimizes travel time for trucks, reduces fuel consumption, and allows for quicker entry and exit, enhancing overall throughput.

Complex routes or congested local roads leading to a terminal can negate many efficiency gains made within the facility itself. Easy access ensures that trucks spend more time on the highway and less time navigating local traffic.

Access to Urban Centers and Industrial Parks

While located near highways, terminals also need proximity to the areas they serve – large urban markets and industrial zones where goods are manufactured or consumed. This balance ensures efficient "last mile" delivery and pickup operations.

Being too far from these centers can lead to excessive local driving, increasing costs and delivery times. The ideal location strikes a balance between mainline access and market reach.

Space for Expansion and Maneuvering

Trucking terminals require significant land. Not only for the building itself but also for extensive truck parking, staging areas, and future expansion. Trailers need ample space to maneuver, dock, and be stored securely.

A lack of sufficient space can lead to congestion, bottlenecks, and safety hazards, severely impacting the terminal’s capacity and efficiency. Planning for future growth is crucial in a dynamic industry.

Regulatory and Zoning Considerations

Local zoning laws and environmental regulations play a significant role in determining where a USA truck terminal can be built. These facilities often generate noise, traffic, and emissions, leading to restrictions in residential or environmentally sensitive areas.

Navigating these regulatory landscapes is a complex but essential part of terminal development. Compliance ensures smooth operation and good community relations.

Labor Availability

Operating a truck terminal requires a substantial workforce, including dockworkers, drivers, mechanics, dispatchers, and administrative staff. Proximity to a skilled labor pool is a vital consideration.

Terminals located in areas with labor shortages or high labor costs can face operational challenges. Access to a stable and qualified workforce is key to consistent, high-quality service.

The Technology Revolutionizing Truck Terminal Operations

The logistics industry is constantly evolving, and technology is at the forefront of this transformation. Modern USA truck terminals are increasingly leveraging advanced solutions to enhance efficiency, safety, and sustainability.

Terminal Management Systems (TMS)

A robust Terminal Management System (TMS) is the digital brain of a modern terminal. These software platforms automate and optimize various operations, from yard management and dock scheduling to freight tracking and labor allocation.

TMS solutions provide real-time visibility into terminal operations, allowing managers to identify bottlenecks, optimize workflows, and make data-driven decisions. This leads to faster throughput and reduced operational costs.

IoT and Telematics

The Internet of Things (IoT) and telematics solutions are transforming how assets are managed within and around trucking terminals. GPS tracking, sensor-equipped trailers, and smart parking systems provide real-time data on truck locations, cargo conditions, and available resources.

This technology enhances security, optimizes yard movements, and enables predictive maintenance for vehicles, reducing unexpected breakdowns and improving fleet uptime.

Automation and Robotics

While full automation is still evolving, many terminals are adopting robotic and automated solutions for repetitive tasks. Automated guided vehicles (AGVs) can move pallets, robotic arms can assist with sorting, and automated gates streamline entry and exit.

These technologies increase speed, reduce labor costs, and improve safety by minimizing human interaction with heavy machinery, especially in hazardous environments.

Advanced Security Systems

Modern security systems go beyond simple cameras. AI-powered surveillance can detect anomalies, identify unauthorized access, and even track specific packages. Drones are being used for perimeter patrols and inventory checks.

These advanced systems provide a comprehensive security blanket, protecting valuable cargo and ensuring the safety of personnel around the clock.

Sustainability Initiatives

As environmental concerns grow, many USA truck terminals are investing in sustainable technologies. This includes installing solar panels, implementing energy-efficient lighting, optimizing HVAC systems, and even installing charging infrastructure for electric trucks.

These initiatives not only reduce the terminal’s carbon footprint but also lead to long-term operational cost savings through reduced energy consumption.

The Impact of Truck Terminals on the American Economy and Daily Life

The cumulative effect of USA truck terminals on the nation is profound and far-reaching. They are silent but powerful engines of economic activity and vital facilitators of our daily lives.

Job Creation

From drivers and mechanics to dispatchers, administrative staff, security personnel, and IT professionals, trucking terminals are significant employers. They provide a wide range of jobs, contributing to local economies across the country.

This job creation extends beyond the terminal walls, supporting industries like manufacturing (trucks, parts), fuel suppliers, and technology developers.

Facilitating Commerce

Every product you see on store shelves, every package delivered to your door, has likely passed through one or more USA truck terminals. They are the indispensable connectors that link manufacturers with retailers and consumers, enabling the vast scale of American commerce.

Without these hubs, the efficient movement of goods would be impossible, leading to higher costs, fewer product choices, and significant economic disruption.

Supporting Local Businesses

Small and medium-sized businesses rely heavily on the efficient logistics services provided by truck terminals. They allow these businesses to ship products across vast distances, reach new markets, and receive essential supplies, all without needing their own extensive logistics infrastructure.

This support is crucial for economic diversification and growth, empowering businesses of all sizes to compete effectively.

Ensuring Product Availability

Imagine a world without readily available goods. USA truck terminals ensure that products are where they need to be, when they need to be there. This reliability supports everything from fresh produce in grocery stores to critical medical supplies in hospitals.

They play a direct role in maintaining the quality of life we often take for granted, ensuring that our essential needs and wants are consistently met.

Pro Tips for Truckers and Logistics Professionals When Dealing with Terminals

Navigating truck terminals can sometimes be challenging. Based on my experience, here are some practical tips for both drivers and logistics managers to ensure smooth operations.

For Drivers:

- Pre-Plan Your Arrival: Always check the terminal’s hours of operation, specific entry/exit procedures, and any parking restrictions. Knowing what to expect saves time and reduces stress.

- Communicate Clearly: Inform dispatch and the terminal of your estimated time of arrival (ETA) and any potential delays. Clear communication prevents misunderstandings and helps the terminal prepare for your load.

- Respect Terminal Rules: Each terminal has specific safety and operational guidelines. Adhere to speed limits, parking instructions, and safety protocols to ensure a safe environment for everyone.

- Have Paperwork Ready: Ensure all necessary documentation (BOLs, manifests, permits) is organized and easily accessible to expedite check-in and check-out processes.

For Logistics Managers:

- Vetting Terminals Thoroughly: Before partnering, evaluate a terminal’s reputation, security measures, maintenance capabilities, and technological infrastructure. Don’t just look at price.

- Optimizing Route Planning: Integrate terminal locations and estimated dwell times into your route optimization software. This helps create realistic schedules and minimizes costly delays.

- Foster Strong Relationships: Building good rapport with terminal staff can be invaluable. Clear communication and mutual respect can help resolve issues more smoothly when they arise.

- Leverage Technology: Utilize real-time tracking and TMS integration to monitor freight status at terminals, proactively addressing potential problems before they escalate.

Common Mistakes to Avoid in Truck Terminal Management

Even with the best intentions, mistakes can occur in terminal management that impact efficiency and profitability. Here are some common pitfalls to avoid:

- Underestimating Security Needs: Assuming "it won’t happen here" is dangerous. Inadequate security measures can lead to theft, damage, and significant financial losses.

- Ignoring Preventative Maintenance: Neglecting vehicle and equipment maintenance leads to breakdowns, costly repairs, and operational disruptions. A proactive approach saves money and ensures reliability.

- Poor Communication Protocols: Lack of clear communication between dispatch, drivers, dockworkers, and management creates confusion, delays, and frustrated personnel.

- Lack of Technological Adoption: Resisting investment in modern TMS, telematics, or automation can leave a terminal lagging behind competitors, struggling with inefficiencies and higher operational costs.

- Inadequate Driver Facilities: Failing to provide basic amenities and a respectful environment for drivers can lead to low morale, high turnover, and difficulty attracting talent.

- Inefficient Yard Management: A disorganized yard leads to wasted time searching for trailers, bottlenecks, and increased risk of accidents. Proper yard planning and management are crucial.

The Future of USA Truck Terminals

The landscape of logistics is constantly shifting, and USA truck terminals are evolving to meet future demands. Several trends are shaping their trajectory.

- Increased Automation and Robotics: Expect to see more autonomous vehicles within terminal yards, robotic sorting systems, and automated loading/unloading processes. This will enhance speed, accuracy, and safety.

- Focus on Sustainability: With growing environmental pressures, terminals will increasingly adopt green technologies, from electric charging infrastructure for fleets to renewable energy sources for their operations.

- Integration with Smart City Infrastructure: Terminals will become more interconnected with urban planning, utilizing data from traffic management systems and delivery networks to optimize freight flow into and out of cities.

- Adapting to E-commerce Growth: The explosion of e-commerce demands faster, more granular delivery. Terminals will adapt by becoming more sophisticated micro-fulfillment centers, handling a higher volume of smaller, time-sensitive parcels.

- Enhanced Data Analytics: Leveraging big data will allow terminals to predict demand, optimize staffing, identify inefficiencies, and make more strategic decisions in real-time.

For further insights into the broader trends impacting the industry, I recommend exploring resources like the American Trucking Associations (ATA) at trucking.org (External Link).

Conclusion: The Indispensable Hubs of American Commerce

USA truck terminals are far more than just points on a map; they are the sophisticated, dynamic hubs that power the American economy. They are where the intricate dance of logistics unfolds, ensuring that goods move seamlessly from production to consumption. From consolidating freight and maintaining vital fleets to providing critical support for drivers, their multifaceted roles are indispensable.

Understanding these critical facilities gives us a deeper appreciation for the complex, dedicated work that underpins our daily lives. As technology advances and supply chains evolve, truck terminals in the USA will continue to adapt, innovate, and remain the unsung heroes, ensuring that America keeps moving forward. The next time you see a semi-truck on the highway, remember the crucial network of terminals working tirelessly behind the scenes to get that cargo where it needs to be.