The Unseen Backbone: A Deep Dive into the USA Truck Terminal Ecosystem

The Unseen Backbone: A Deep Dive into the USA Truck Terminal Ecosystem Typestruck.Guidemechanic.com

In the vast, intricate network that fuels the American economy, few components are as critical yet as often overlooked as the humble USA truck terminal. These bustling hubs are far more than just parking lots for big rigs; they are the beating hearts of our nation’s logistics, facilitating the seamless flow of goods from manufacturers to consumers across thousands of miles. As an expert in logistics and supply chain optimization, I’ve spent years observing and working within these vital facilities, and I can tell you, their efficiency directly impacts everything from the price of your groceries to the speed of your online deliveries.

This comprehensive guide will pull back the curtain on USA truck terminals, exploring their pivotal role, diverse types, sophisticated operations, and the cutting-edge technologies shaping their future. Our goal is to provide a pillar resource for anyone seeking to understand the true engine behind America’s freight movement.

The Unseen Backbone: A Deep Dive into the USA Truck Terminal Ecosystem

What Exactly is a USA Truck Terminal? Understanding the Core Concept

At its essence, a USA truck terminal is a central facility where freight is transferred, sorted, consolidated, and dispatched for further transportation. Think of it as a strategic interchange on the highway of commerce, a crucial pit stop where cargo changes hands, trucks get serviced, and drivers rest. These facilities are designed for efficiency, acting as critical nodes in both Less-Than-Truckload (LTL) and Full-Truckload (FTL) operations.

Based on my experience, the distinction between a simple truck stop and a full-fledged truck terminal is vital. While a truck stop primarily caters to driver needs – fuel, food, rest – a terminal’s core function revolves around freight handling and vehicle management, often on a massive scale. It’s a logistical operations center, not just a convenience hub.

These terminals are indispensable for breaking down large shipments into smaller, manageable loads, or conversely, combining multiple smaller shipments into full truckloads destined for a single region. This process, known as cross-docking or consolidation, is a cornerstone of modern supply chain efficiency, reducing costs and transit times significantly.

The Vital Role of Truck Terminals in the American Supply Chain

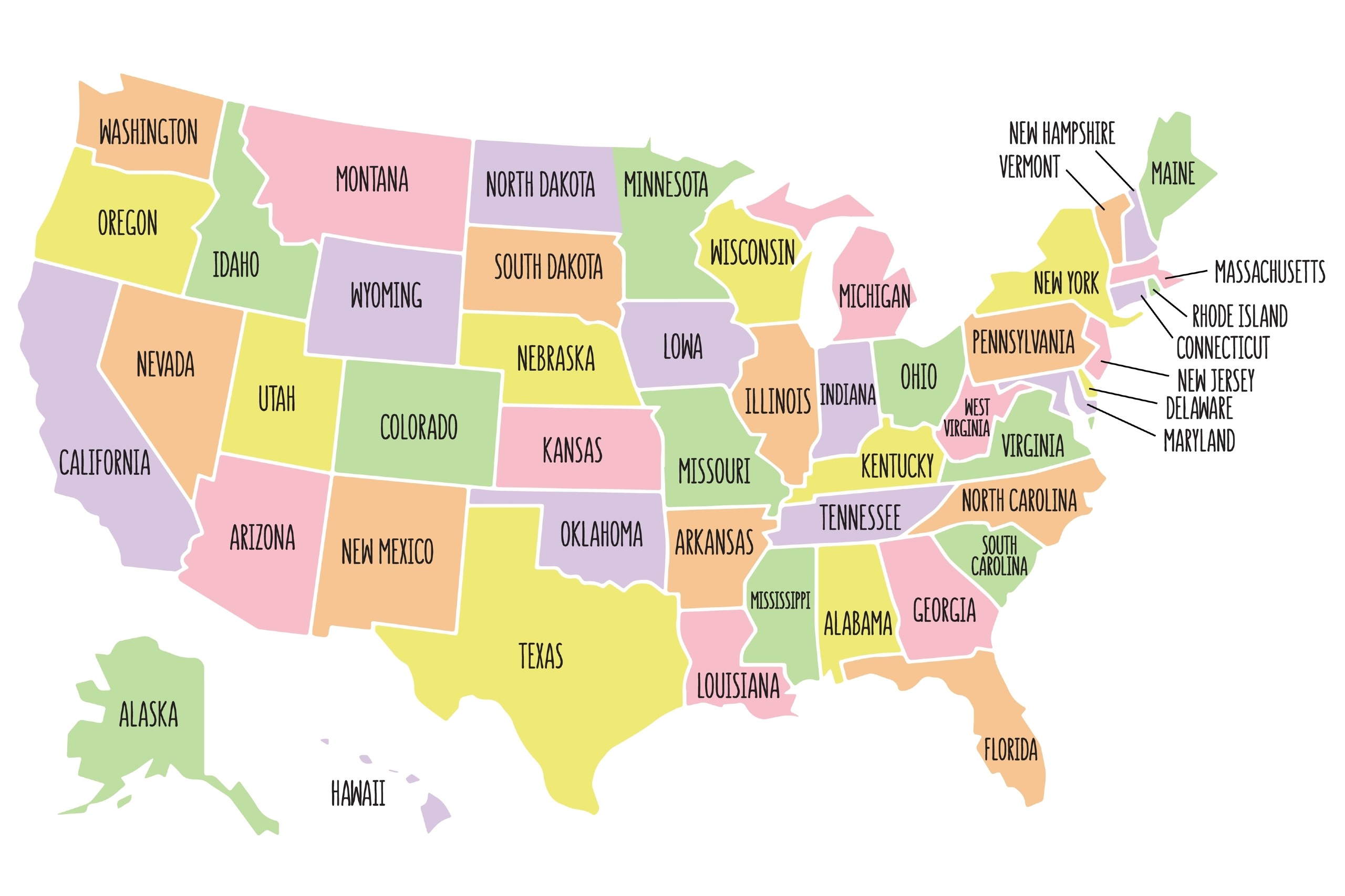

The United States, with its vast geographical expanse and robust economy, relies heavily on ground transportation for the movement of goods. USA truck terminals are the linchpins that connect manufacturers, warehouses, distribution centers, and retail outlets nationwide. Without them, the intricate dance of supply and demand would grind to a halt.

From a macroeconomic perspective, these terminals enable just-in-time inventory management, reducing the need for costly warehousing space at every step of the supply chain. They facilitate regional distribution, allowing goods produced in one part of the country to quickly reach markets thousands of miles away. This seamless connectivity is a testament to their strategic placement and operational sophistication.

Furthermore, truck terminals are significant employers, creating jobs for drivers, logistics coordinators, mechanics, administrative staff, and security personnel. They contribute substantially to local economies, often acting as anchors for industrial parks and commercial zones. Their impact extends far beyond just moving goods; they are economic engines in their own right.

Types of USA Truck Terminals: A Deeper Dive

Not all truck terminals are created equal. Their design and operational focus vary widely depending on the specific logistical challenges they address. Understanding these distinctions is key to appreciating their versatility.

Cross-Dock Terminals

Cross-dock terminals are perhaps the most common and pivotal type in the LTL industry. Their primary function is to quickly transfer freight from inbound trucks to outbound trucks with minimal storage time. Goods are typically unloaded from one side of a dock, sorted, and then immediately reloaded onto another truck on the opposite side, hence the term "cross-dock."

This rapid transfer process significantly reduces warehousing costs and accelerates delivery times. Based on my observations, a well-designed cross-dock operation can move freight through the facility in a matter of hours, a stark contrast to traditional warehousing where goods might sit for days or weeks. Common mistakes to avoid in cross-docking include inefficient sorting systems and inadequate dock door capacity, which can create bottlenecks.

Breakbulk Terminals

Breakbulk terminals handle larger, often unpackaged or non-containerized cargo that needs to be divided or consolidated. While some cross-dock facilities can handle breakbulk, dedicated breakbulk terminals are designed for more specialized, heavier, or irregularly shaped items. They might feature specialized equipment like cranes or larger staging areas.

These terminals are crucial for industries dealing with oversized equipment, raw materials, or components that don’t fit standard pallet dimensions. They bridge the gap between various modes of transport, often acting as consolidation points before goods are loaded onto specialized trucks for final delivery.

Intermodal Terminals

Intermodal terminals are fascinating hubs where freight seamlessly transitions between different modes of transportation, primarily truck, rail, and sometimes sea or air. These facilities are critical for long-haul freight movement, leveraging the cost-effectiveness of rail for long distances and the flexibility of trucks for first and last-mile delivery.

Pro tips from us: utilizing intermodal transport can dramatically reduce fuel costs and carbon emissions for long-distance hauls. The coordination required in these terminals is immense, involving precise scheduling and robust handling equipment to transfer containers efficiently between trains and trucks. The rise of containerization has made intermodal terminals increasingly vital to global and national supply chains.

Distribution Centers with Terminal Functions

Many large distribution centers (DCs) integrate truck terminal functionalities, especially those serving regional markets. While a DC’s primary role is storage and order fulfillment, they often have extensive docks for receiving inbound freight and dispatching outbound deliveries. These facilities act as both a warehouse and a major transfer point.

For e-commerce giants, these integrated facilities are paramount. They allow for rapid processing of orders, direct loading onto delivery trucks, and efficient management of a diverse product inventory. The line between a traditional warehouse and a sophisticated terminal often blurs in these modern, high-volume operations.

Driver Service and Rest Terminals (Enhanced Truck Stops)

While not terminals in the traditional freight-handling sense, many large, modern truck stops have evolved to offer terminal-like services beyond just fuel and food. These facilities might include extensive parking, truck wash services, basic maintenance bays, weigh stations, and even designated areas for drop-and-hook operations for major carriers.

They serve as crucial support infrastructure for drivers, enabling them to comply with hours-of-service regulations while providing essential vehicle upkeep. While not directly involved in freight transfer, their existence supports the operational capacity of the entire trucking network by keeping drivers and trucks on the road safely and efficiently.

Key Functions and Operations Within a Terminal

The daily rhythm of a USA truck terminal is a complex symphony of coordinated activities. Each function is critical to ensuring freight moves efficiently and securely.

Freight Handling: Loading, Unloading, and Sorting

This is the core activity. Forklifts, pallet jacks, and sometimes automated systems move thousands of pounds of freight daily. Inbound freight is meticulously unloaded, scanned, and then sorted based on its destination. Outbound freight is consolidated and loaded onto waiting trailers, ensuring proper weight distribution and securement.

Based on my observations, accuracy in sorting is paramount to prevent misdeliveries, which can be incredibly costly in terms of time and customer satisfaction. Advanced scanning technologies and robust Warehouse Management Systems (WMS) are critical tools here.

Vehicle Maintenance & Repair

Trucks are the lifeblood of the terminal, and keeping them operational is non-negotiable. Many larger terminals have dedicated maintenance bays equipped to handle everything from routine oil changes and tire repairs to more complex engine diagnostics. This in-house capability minimizes downtime, a critical factor in a time-sensitive industry.

Preventative maintenance is a pro tip for any fleet owner. Regular checks conducted at terminals can catch minor issues before they become major breakdowns on the road, ensuring safety and reliability.

Driver Support & Amenities

Terminals recognize that drivers are their most valuable asset. Facilities often include comfortable lounges, showers, laundry services, and sometimes even medical clinics or fitness centers. Providing a welcoming environment helps combat driver fatigue and improves overall morale.

This focus on driver well-being is not just good practice; it’s essential for retention in an industry constantly battling driver shortages. A well-rested and supported driver is a safer and more efficient driver.

Fleet Management & Dispatch

The nerve center of any terminal is its dispatch office. Here, logistics professionals manage driver assignments, track shipments, optimize routes, and communicate with customers. They are responsible for ensuring that trucks are loaded correctly and dispatched on time, adhering to strict delivery schedules.

Modern dispatch systems integrate GPS tracking, real-time traffic data, and weather forecasts to make informed decisions, constantly adapting to unforeseen challenges. For a deeper dive into supply chain efficiency, explore our guide on .

Security Measures

Given the high value of the cargo often handled, security is a top priority. Terminals employ a range of measures, including 24/7 surveillance, controlled access points, perimeter fencing, and trained security personnel. Cargo theft is a persistent threat, and robust security protocols are essential to protect goods and assets.

Implementing strict check-in/check-out procedures for drivers and ensuring proper sealing of trailers are common practices. Investing in advanced security technology provides peace of mind for both carriers and shippers.

Technology Driving Modern Truck Terminals

The logistics industry is in a constant state of technological evolution, and USA truck terminals are at the forefront of this transformation. Technology isn’t just an add-on; it’s integrated into every aspect of operations to enhance efficiency, safety, and transparency.

Terminal Management Systems (TMS)

TMS software is the brain of a modern terminal. It optimizes scheduling, tracks inventory within the yard, manages dock door assignments, and provides real-time visibility into freight movement. This comprehensive platform streamlines operations and reduces manual errors.

Based on my experience, a robust TMS can significantly improve throughput and reduce dwell times, which are critical metrics for terminal efficiency. It allows managers to make data-driven decisions, optimizing resource allocation and workflow.

IoT & Telematics

Internet of Things (IoT) devices and telematics systems are revolutionizing fleet and cargo tracking. Sensors on trucks and trailers provide real-time data on location, speed, fuel consumption, tire pressure, and even cargo temperature. This data is invaluable for proactive maintenance and security.

Pro tips: Telematics data can be used to monitor driver behavior, identify areas for efficiency improvements, and even predict potential mechanical failures before they occur. If you’re interested in optimizing your fleet, read our article on .

Automation & Robotics

While still evolving, automation is making inroads into terminals. Automated Guided Vehicles (AGVs) can move trailers within the yard, and robotic arms are being tested for sorting and loading certain types of freight. Automated gate systems use RFID and cameras to process trucks quickly upon entry and exit.

The goal of automation isn’t necessarily to replace human labor entirely, but to augment it, especially for repetitive or hazardous tasks, thereby increasing safety and efficiency.

Data Analytics

Every action within a terminal generates data. Modern terminals leverage big data analytics to identify bottlenecks, predict demand fluctuations, optimize labor scheduling, and improve overall operational performance. This data-driven approach allows for continuous improvement and strategic planning.

Understanding historical trends and real-time metrics helps terminal operators adapt quickly to changing market conditions and maximize their operational footprint.

Choosing the Right Truck Terminal: What to Look For

For carriers, shippers, or logistics providers, selecting the right truck terminal partner is a strategic decision. Here are some pro tips on what to consider:

- Location: Proximity to major highways, industrial parks, and your customer base is paramount. A strategically located terminal can significantly reduce transit times and fuel costs.

- Capacity & Throughput: Ensure the terminal has sufficient dock doors, yard space, and operational capacity to handle your volume, especially during peak seasons. Overcrowding leads to delays.

- Technology Integration: A terminal utilizing modern TMS, telematics, and security systems indicates efficiency and reliability. Ask about their tracking capabilities and data transparency.

- Security Protocols: Inquire about their security measures, including surveillance, access control, and personnel. Protecting your cargo is non-negotiable.

- Maintenance & Support Services: For carriers, the availability of maintenance, fueling, and driver amenities can be a significant advantage, minimizing off-site stops.

- Reputation & Customer Service: Look for terminals with a proven track record of reliability and responsiveness. Read reviews and ask for references.

Common mistakes to avoid are choosing a terminal solely based on price without considering its operational efficiency or security. A cheaper option can quickly become more expensive due to delays, damages, or theft.

Challenges Faced by USA Truck Terminals

Despite their critical importance, USA truck terminals contend with a myriad of challenges that impact their operations and the broader supply chain.

Capacity Constraints

Many terminals, particularly in high-density urban areas, struggle with limited space. Expanding existing facilities is often difficult due to land availability and zoning regulations. This capacity crunch can lead to yard congestion, increased dwell times for trailers, and operational inefficiencies.

The rapid growth of e-commerce has only exacerbated this issue, demanding quicker turnaround times and more frequent deliveries, putting immense pressure on existing infrastructure.

Labor Shortages

The trucking industry faces persistent labor shortages, not just for drivers but also for skilled mechanics, dockworkers, and logistics personnel within terminals. Attracting and retaining talent is a constant battle, impacting operational capacity and increasing labor costs.

Investing in training programs, competitive wages, and creating a positive work environment are crucial strategies for addressing this challenge.

Environmental Regulations

Increasingly stringent environmental regulations regarding emissions, noise pollution, and waste management pose significant challenges. Terminals are under pressure to adopt greener practices, such as electrifying yard equipment, optimizing routes to reduce idling, and implementing sustainable waste disposal methods.

While beneficial for the planet, these changes often require substantial capital investment and operational adjustments.

Infrastructure Limitations

The surrounding road infrastructure, especially near older terminals or those in growing urban areas, can be a major bottleneck. Congested roadways, inadequate access points, and aging bridges can slow down inbound and outbound traffic, negating internal terminal efficiencies.

Investing in regional infrastructure improvements is vital for the long-term efficiency of the entire trucking ecosystem. (Source: External Link Placeholder: American Trucking Associations – Industry Trends)

Security Risks

Cargo theft remains a significant concern, with organized crime groups continually targeting high-value goods. Terminals must constantly upgrade their security measures to stay ahead of evolving threats, investing in advanced surveillance, access control, and personnel training.

The cost of robust security is substantial, but it’s an unavoidable expense given the potential losses from theft.

The Future of USA Truck Terminals: Trends and Innovations

The landscape of USA truck terminals is continuously evolving, driven by technological advancements, changing consumer demands, and a push for greater sustainability.

Sustainability & Green Logistics

The industry is moving towards greener operations. Expect to see more electric yard hostlers, charging infrastructure for electric trucks, and solar panels powering terminal facilities. The focus will be on reducing the carbon footprint of freight movement through optimized routing and energy-efficient operations.

"Green terminals" will become a competitive advantage, attracting environmentally conscious partners and employees.

Increased Automation & AI

Automation will continue to advance, with AI-powered systems optimizing everything from dock scheduling to predictive maintenance. Autonomous yard trucks and even potentially autonomous long-haul vehicles will reshape how freight moves into and out of terminals, though widespread adoption will take time.

The integration of artificial intelligence will allow for more dynamic decision-making, adapting to real-time changes in weather, traffic, and demand.

E-commerce Impact & Last-Mile Optimization

The explosion of e-commerce means terminals will play an even more critical role in last-mile delivery. We’ll see more urban micro-terminals or "sortation centers" designed for rapid package handling and distribution within metropolitan areas, shortening delivery times.

This shift necessitates smaller, more agile facilities capable of handling a higher volume of individual parcels rather than large bulk shipments.

Enhanced Driver Experience

As the driver shortage persists, terminals will continue to invest in amenities and technologies that improve the driver experience. This includes better rest facilities, telemedicine services, advanced communication tools, and streamlined check-in/check-out processes.

The "driver-centric" terminal will become a standard, recognizing that supporting drivers is key to supporting the entire supply chain.

Smart Terminals

The ultimate vision is a "smart terminal" – a fully interconnected ecosystem where all systems, from gates to forklifts to trucks, communicate in real-time. This level of integration will unlock unprecedented levels of efficiency, predictive capabilities, and security.

Think of it as a living, breathing organism, constantly optimizing itself to move freight with maximum speed and minimal waste.

Conclusion: The Enduring Importance of USA Truck Terminals

The USA truck terminal is far more than just a logistical waypoint; it is an indispensable component of the American economy, a complex operational hub that keeps goods flowing and businesses thriving. From cross-docking brilliance to intermodal ingenuity, these facilities are constantly adapting, innovating, and overcoming challenges to meet the relentless demands of modern commerce.

As an expert who has witnessed the incredible transformation within this sector, I can confidently say that understanding the inner workings and strategic importance of USA truck terminals is crucial for anyone involved in supply chain, logistics, or even just curious about how products reach their destination. They are the unseen backbone, the silent workhorses, ensuring that the wheels of our economy never stop turning. The future promises even more sophisticated, sustainable, and efficient terminals, solidifying their role as pivotal players in the global supply chain.