The Ultimate Guide to Welding Trucks For Sale in Texas: Your Roadmap to the Perfect Rig

The Ultimate Guide to Welding Trucks For Sale in Texas: Your Roadmap to the Perfect Rig Typestruck.Guidemechanic.com

Texas, with its sprawling landscapes and booming industries, is a land of opportunity for skilled welders. From the oil and gas fields to massive infrastructure projects and ever-expanding urban developments, the demand for precise and robust welding services is constant. For any professional welder aiming to capitalize on this vibrant market, a reliable and well-equipped welding truck isn’t just a convenience – it’s an absolute necessity.

If you’re searching for "Welding Trucks For Sale Texas," you’re on the right path to empowering your career. This comprehensive guide will navigate you through every critical aspect of finding, evaluating, and acquiring the perfect mobile welding rig that will serve as the backbone of your operations in the Lone Star State. We’ll delve deep into what makes a great welding truck, where to find them, and how to make an informed decision that drives your success.

The Ultimate Guide to Welding Trucks For Sale in Texas: Your Roadmap to the Perfect Rig

Why Texas? The Heart of Welding Opportunities

Texas isn’t just big; it’s big on industry. The state’s economic engine is fueled by diverse sectors, including oil and gas exploration and refining, heavy construction, manufacturing, and even renewable energy projects. Each of these industries relies heavily on welding for fabrication, maintenance, and repair, creating a continuous and high demand for expert welders.

The sheer geographical size of Texas also means that work often takes welders to remote locations, far from established workshops. This makes a self-sufficient mobile welding unit indispensable. Having your entire setup on wheels allows you to respond quickly to jobs across Houston, Dallas-Fort Worth, San Antonio, Corpus Christi, and beyond, significantly expanding your earning potential. The market for "Welding Trucks For Sale Texas" is robust precisely because the work is plentiful and widespread.

Understanding Your Needs: What Kind of Welder Are You?

Before you even begin browsing "Welding Trucks For Sale Texas," the most crucial step is to define your specific welding niche and operational requirements. Not all welding trucks are created equal, and what works for a pipeline welder might be overkill for a custom fabrication specialist.

Based on my experience, understanding your niche is the first step toward making a smart investment. Are you primarily involved in heavy-duty structural welding, requiring robust lifting capabilities? Or do you focus on intricate pipe welding, where precision and specialized tools are paramount?

Consider the types of jobs you typically undertake. Mobile repair services often need a versatile setup, capable of handling various materials and processes on-site. Pipeline welders, conversely, demand extreme durability, off-road capability, and ample storage for long hauls in challenging terrain. Your answers to these questions will heavily influence the truck’s chassis, engine, welding machine type, and body configuration.

Components of a Top-Tier Welding Truck Setup

A truly effective welding truck is more than just a vehicle; it’s a meticulously organized mobile workshop. Each component plays a vital role in your efficiency, safety, and productivity. When evaluating "Welding Trucks For Sale Texas," pay close attention to the integration and condition of these key elements.

The Truck Itself: The Foundation of Your Rig

The vehicle chassis is the literal foundation of your mobile welding operation. For heavy-duty applications common in Texas, you’ll typically be looking at 3/4-ton or 1-ton trucks, such as Ford F-250/F-350, Ram 2500/3500, or Chevrolet Silverado 2500HD/3500HD. These trucks offer the necessary payload capacity to safely carry your welding machine, tools, gases, and other equipment.

Engine choice is another critical factor. Diesel engines are favored by many professional welders for their superior torque, fuel efficiency under heavy loads, and longevity, especially when running PTO-driven equipment or towing. However, modern gasoline engines have significantly improved and can be a more cost-effective option for lighter-duty or less frequent heavy hauling. Consider the terrain you’ll encounter; 4×4 capability is often essential for accessing remote job sites, particularly in rural Texas.

The Welding Machine: Your Core Tool

This is the heart of your operation. Most professional welding trucks feature a powerful engine-driven welder/generator. These units provide both welding current and auxiliary power for grinders, lights, and other electrical tools.

When looking at "Welding Trucks For Sale Texas," assess the welder’s amperage output, its multi-process capabilities (Stick, MIG, TIG, Flux-cored), and the brand’s reputation for reliability. Leading brands like Lincoln Electric, Miller Electric, and ESAB are industry standards for a reason, offering robust performance and excellent support. Ensure the machine’s capacity matches the demands of your typical welding projects.

The Service Body or Flatbed: Organized Storage and Access

The way your equipment is stored and accessed directly impacts your efficiency. Service bodies, with their multiple external compartments, offer excellent organization and weather protection for tools and consumables. They keep everything tidy and secure, minimizing setup time on job sites.

Alternatively, a flatbed with strategically placed toolboxes can provide more flexibility for carrying larger, irregularly shaped items or for mounting specialized equipment like cranes. Consider the material of the body – steel offers maximum durability, while aluminum is lighter and corrosion-resistant, which can improve fuel economy. Pro tips from us: Look for robust drawer slides, secure locking mechanisms, and ample space for all your essential gear.

Air Compressor: Powering Pneumatic Tools

Many welding operations benefit from an onboard air compressor. This powers air tools like grinders, impact wrenches, and plasma cutters, significantly increasing your versatility.

When reviewing "Welding Trucks For Sale Texas," check the compressor’s CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) ratings to ensure it meets your tool requirements. Integrated systems that run off the truck’s engine are highly efficient, but dedicated standalone units are also common.

Oxygen/Acetylene Tanks: Essential for Cutting and Heating

Safe and secure storage for oxygen and acetylene tanks is non-negotiable. Look for dedicated, properly secured racks or compartments that meet safety regulations. These tanks are crucial for cutting, heating, and gouging operations, making their proper integration into your truck design paramount.

Tools & Accessories: The Details That Matter

Beyond the major components, a well-outfitted welding truck includes an array of essential tools and accessories. This includes various grinders, cutting torches, clamps, welding helmets, safety gear, fire extinguishers, and first-aid kits. Pro tips from us: Don’t skimp on quality safety gear; your personal well-being is invaluable. Also, consider the organization of these smaller items within the truck to maximize efficiency on every job.

New vs. Used Welding Trucks For Sale Texas: Making the Right Choice

Deciding between a new and a used welding truck is a significant financial consideration. Both options present distinct advantages and disadvantages, and the best choice depends on your budget, immediate needs, and risk tolerance.

New Welding Trucks

Pros:

- Warranty and Reliability: New trucks come with factory warranties, offering peace of mind against unexpected repairs. All components are new, ensuring maximum reliability from day one.

- Latest Technology: You’ll benefit from the newest engine technologies, safety features, and welding machine advancements, often leading to better fuel efficiency and performance.

- Customization: Buying new allows for full customization of the chassis, body, and welding equipment to perfectly match your specific operational needs.

Cons:

- Higher Cost: The initial investment for a new welding truck is significantly higher, which can be a barrier for independent welders or startups.

- Depreciation: New vehicles experience rapid depreciation in their first few years, meaning you lose value quickly.

Used Welding Trucks

Pros:

- Cost-Effectiveness: Used trucks are considerably more affordable, allowing you to acquire a capable rig without breaking the bank. This can be a huge advantage for maximizing profit margins.

- Immediate Availability: You can often drive away with a used truck much faster than waiting for a custom-built new one.

- Proven Reliability (Sometimes): A well-maintained used truck from a reputable seller can offer years of reliable service.

Cons:

- Unknown History: The biggest risk with used trucks is hidden issues or a lack of maintenance history. Common mistakes to avoid are not getting a pre-purchase inspection from an independent mechanic.

- Wear and Tear: Components, especially the welding machine, will have accumulated hours of use. Evaluate the condition of the engine, transmission, and the welder itself very carefully.

- Limited Customization: You’re buying an existing setup, so customization options are limited to modifications rather than starting from scratch.

When considering "used Welding Trucks For Sale Texas," always request maintenance records, scrutinize the frame for rust or damage, and test every piece of equipment, especially the welder/generator. A thorough inspection is non-negotiable.

Where to Find Welding Trucks For Sale in Texas

Texas offers a wide array of avenues for finding your next welding rig, catering to different budgets and preferences. Knowing where to look can significantly streamline your search for "Welding Trucks For Sale Texas."

1. Specialized Dealerships

Many commercial truck dealerships and equipment suppliers across Texas specialize in work trucks and can often source or build welding rigs. These dealerships, found in major hubs like Houston, Dallas, San Antonio, and smaller industrial towns, offer financing options, warranties (on new trucks), and professional sales support. They often have a deep understanding of the specific needs of welders.

2. Online Marketplaces & Classifieds

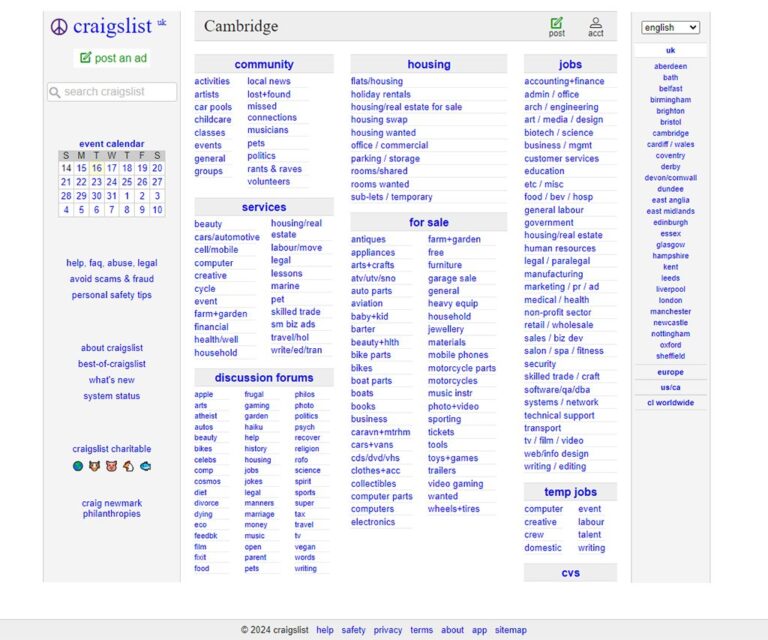

The digital realm is a powerful tool for your search. Websites like TruckPaper.com, EquipmentTrader.com, and IronPlanet.com are dedicated to heavy equipment and commercial vehicles, often listing "Welding Trucks For Sale Texas" from both dealerships and private sellers. For a broader, more localized search, Craigslist and Facebook Marketplace can also yield results, but exercise extreme caution and always prioritize in-person inspections.

3. Auctions

Equipment auctions, both physical and online, can be excellent places to find deals on used welding trucks. Government surplus auctions, private industrial auctions, and specialized heavy equipment auctioneers frequently have a variety of trucks available. While prices can be attractive, remember that auction items are typically sold "as-is," meaning thorough pre-bidding inspection is even more critical.

4. Private Sellers & Networking

Sometimes, the best deals come from other welders or small businesses looking to upgrade or retire their equipment. Networking within the welding community, checking local trade publications, or even "for sale" signs on trucks can lead you to a diamond in the rough. These sales often involve less overhead, potentially leading to better prices.

The Buying Process: A Step-by-Step Guide

Once you’ve identified potential "Welding Trucks For Sale Texas," navigating the buying process carefully will ensure you make a sound investment.

1. Define Your Budget (and Stick to It): Beyond the sticker price, factor in potential repairs, insurance, registration, and any immediate upgrades you plan to make. Have a clear maximum spend in mind.

2. Research Thoroughly: Compare similar models, features, and market prices. Understand what constitutes a fair deal for the condition and specifications of the truck you’re considering. This research empowers you during negotiation.

3. Inspect (or Hire an Inspector): For used trucks, a professional pre-purchase inspection by an independent mechanic is non-negotiable. They can identify underlying mechanical issues that might not be obvious to the untrained eye, including frame damage, engine problems, or transmission wear. Don’t forget to thoroughly test the welding machine itself.

4. Test Drive: Get behind the wheel. Pay attention to how the truck handles, the responsiveness of the engine and brakes, and any unusual noises. Test it with some weight in the bed if possible, to simulate real-world conditions.

5. Negotiate: Don’t be afraid to negotiate the price. Based on your research and any inspection findings, present a reasonable offer. Be prepared to walk away if the deal isn’t right for you. Pro tip: Always get everything in writing, including the final price, any agreed-upon repairs, and the terms of sale.

6. Financing & Insurance: Explore financing options if needed, whether through a dealership, bank, or credit union. Secure appropriate commercial insurance before you drive the truck off the lot. Insurance requirements for commercial vehicles can be different from personal vehicles.

7. Paperwork: Ensure all titles, registration documents, and bills of sale are correctly filled out and transferred. Verify the VIN on the truck matches the paperwork.

Customization and Outfitting Your Welding Rig

Acquiring a welding truck is just the first step; outfitting it to maximize your efficiency and safety is equally important. Even if you purchase a pre-built rig from "Welding Trucks For Sale Texas," there’s usually room for personalized touches.

Consider installing additional tool organization solutions, such as custom racks, drawers, or shelving in your service body compartments. Proper lighting, including work lights for night jobs and safety strobes for roadside visibility, is crucial. An inverter can provide AC power for smaller tools and charging devices directly from your truck’s battery.

Always prioritize safety features. Beyond the essentials, think about adding backup cameras, heavy-duty fire extinguishers, and comprehensive first-aid kits. Finally, don’t underestimate the power of professional branding. A well-maintained truck with your company logo and contact information acts as a mobile billboard, attracting new clients wherever you go. For more detailed advice on setting up your mobile welding workshop, check out our guide on .

Legal and Regulatory Considerations in Texas

Operating a commercial welding truck in Texas comes with specific legal and regulatory obligations. Staying compliant is essential to avoid fines, ensure safety, and maintain your professional standing.

Based on my experience, understanding these regulations is non-negotiable. Depending on the truck’s Gross Vehicle Weight Rating (GVWR) and how you use it, you might need a Commercial Driver’s License (CDL). Your truck will also be subject to Department of Transportation (DOT) regulations regarding vehicle maintenance, inspections, and hours of service if you cross state lines or operate above certain weight thresholds.

Ensure your truck meets all state and federal safety inspection requirements. Proper vehicle registration and adequate commercial liability insurance are also mandatory. Consult with a commercial vehicle insurance specialist to ensure you have comprehensive coverage tailored to your specific operations in Texas.

Maintenance and Longevity: Protecting Your Investment

Your welding truck is a significant investment and a critical asset to your business. Regular and proactive maintenance is key to maximizing its lifespan, ensuring reliability, and minimizing costly downtime.

Beyond the standard vehicle maintenance like oil changes, tire rotations, and brake checks, pay special attention to the truck’s suspension and frame. Carrying heavy welding equipment puts extra strain on these components. Regularly inspect the service body or flatbed for cracks, rust, or loose fasteners.

The welding machine itself also requires routine care. Keep it clean, check cables for wear, and follow the manufacturer’s guidelines for servicing and calibration. A well-maintained welder will perform consistently and last much longer. To extend the life of your valuable equipment, explore our tips on . Proactive maintenance not only saves money in the long run but also ensures your rig is always ready for the next big job across Texas.

Conclusion: Your Road to Success Starts Here

Acquiring the right welding truck is a pivotal decision for any professional welder in Texas. It’s more than just a vehicle; it’s your mobile workshop, your reputation on wheels, and a direct enabler of your earning potential in one of the nation’s most dynamic industrial landscapes. By carefully considering your needs, thoroughly evaluating your options for "Welding Trucks For Sale Texas," and committing to proper maintenance, you’re not just buying a truck – you’re investing in the future of your business.

Remember to prioritize safety, efficiency, and reliability in every aspect of your choice. With the right welding rig, you’ll be well-equipped to tackle any project, anywhere in Texas, confidently driving your career forward. The opportunities are vast, and with this guide, you’re now better prepared to seize them.

External Link: For general heavy equipment listings, including commercial trucks, you can visit TruckPaper.com. (Note: This is a widely recognized and trusted resource in the heavy equipment industry.)