The Ultimate Guide to a Professional Farrier Truck Setup: Optimize Your Mobile Workshop

The Ultimate Guide to a Professional Farrier Truck Setup: Optimize Your Mobile Workshop Typestruck.Guidemechanic.com

As a farrier, your truck isn’t just a mode of transport; it’s your mobile workshop, your office, and often, your brand’s first impression. A well-organized and efficiently designed farrier truck setup is paramount to your success, impacting everything from your daily workflow and productivity to your physical well-being and the longevity of your tools. Imagine spending less time searching for a tool and more time focused on the horse – that’s the power of an optimized mobile farrier workshop.

This comprehensive guide will delve deep into every aspect of creating an exceptional farrier rig, transforming it from a simple vehicle into a highly functional and professional workspace. We’ll cover everything from choosing the right base vehicle to specialized storage solutions, power systems, and crucial safety considerations. Our goal is to provide you with the insights and practical tips to build a professional farrier setup that truly elevates your business.

The Ultimate Guide to a Professional Farrier Truck Setup: Optimize Your Mobile Workshop

Why a Well-Organized Farrier Truck Setup is Non-Negotiable

A haphazardly organized truck can be a significant drain on your time, energy, and finances. Every minute spent rummaging for a rasp or a specific size shoe is a minute lost that could be spent on a paying client or enjoying some downtime. This inefficiency directly impacts your bottom line.

Based on my experience, a disorganized truck isn’t just an inconvenience; it’s a constant source of frustration and a barrier to peak performance. It can lead to damaged tools, forgotten supplies, and even a less professional image in the eyes of your clients. A tidy and logical setup, conversely, projects an image of competence and attention to detail.

Beyond efficiency, a proper farrier truck setup is crucial for safety. Tools that are not secured can become dangerous projectiles during sudden stops or accidents. Moreover, a cluttered workspace increases the risk of trips, falls, and cuts, which no farrier wants to experience, especially when working alone on a remote farm. Investing time in organization is an investment in your safety and the safety of those around you.

Choosing the Right Vehicle Base for Your Farrier Rig

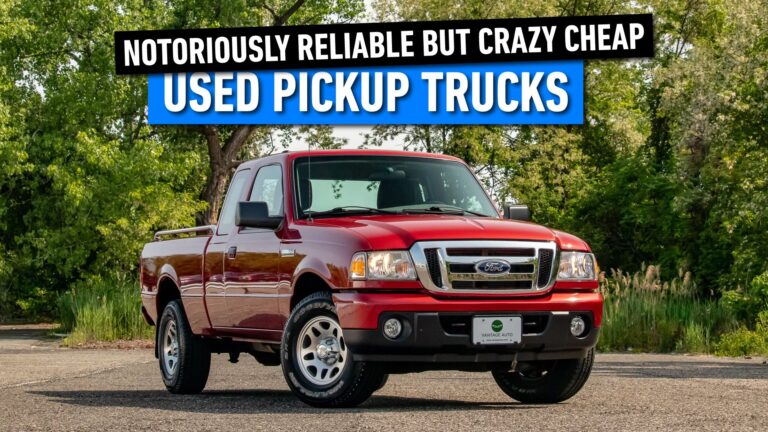

The foundation of your mobile farrier workshop begins with the vehicle itself. The choice between a pickup truck, a utility body truck, a van, or even a small box truck depends heavily on your specific needs, the type of work you do, and your budget. Each option presents unique advantages and challenges for a farrier truck organization system.

Pickup Trucks with Service Bodies: These are arguably the most popular choice among farriers. The service body, often made of steel or aluminum, offers multiple exterior compartments with secure, weather-tight storage. This design keeps your tools and supplies organized and protected from the elements, while also providing a flatbed area for larger items like a forge or anvil stand.

Pro tips from us: When considering a pickup with a service body, pay close attention to the payload capacity. Farrier equipment, shoes, and materials are incredibly heavy, and exceeding your vehicle’s weight limits can be dangerous, illegal, and lead to premature wear and tear on your truck. Always factor in the weight of your tools, supplies, and the body itself.

Vans (Cargo Vans): Vans, particularly high-roof cargo vans, offer an enclosed, climate-controlled workspace. This can be a huge advantage in harsh weather, allowing you to stand and work within the vehicle. They provide ample wall space for shelving, bins, and custom cabinetry, making them excellent for a highly customized farrier van conversion.

Common mistakes to avoid are underestimating the importance of interior ventilation in a van, especially if you plan to do any hot work or use chemicals inside. Proper airflow is essential for safety and comfort. Additionally, security can be a concern with vans, so robust locking systems are a must.

Utility Trucks and Box Trucks: While less common for solo farriers, these larger vehicles offer the most expansive space for customization. They can accommodate more tools, larger equipment, and potentially a dedicated office space. These are often chosen by farriers who operate with multiple apprentices or require an extensive inventory of specialized shoes and supplies. The trade-off is often higher fuel consumption and reduced maneuverability.

Regardless of the base vehicle, consider crucial factors like four-wheel drive for accessing remote properties, fuel efficiency for long days on the road, and the vehicle’s overall reliability. A breakdown can cost you multiple appointments and significant revenue, so investing in a dependable vehicle is paramount.

Essential Zones and Layout Principles for Your Mobile Farrier Workshop

Designing an effective layout for your farrier truck setup is about creating a logical workflow that minimizes wasted motion and maximizes productivity. Think of your truck as a miniature factory, where each process has its dedicated space. A well-planned layout considers the sequence of tasks you perform most frequently.

The Forging/Hot Work Zone: This is arguably the most critical and potentially hazardous area. It needs to be easily accessible and safe. Typically located at the rear of a service body or near the rear doors of a van, this zone houses your forge, anvil, anvil stand, and quench tank.

Based on my experience, having a clear, flat, and stable area around your anvil is crucial for safety and effective work. Ensure adequate ventilation if working in an enclosed space, and always have a fire extinguisher immediately at hand. The placement of your propane tank should also be considered, typically mounted externally and securely.

Tool Storage Zone: This encompasses all your hand tools, power tools, and specialized instruments. Organization here is key to efficiency. Tools should be stored in a way that makes them visible and easily retrievable, without having to dig through layers of other equipment.

Pro tips from us: Group similar tools together. All your nippers in one drawer, rasps in another, and hoof knives in a protected, accessible spot. Utilizing custom inserts or foam cutouts can significantly improve organization and protect delicate tools from rattling and damage.

Stock/Material Storage Zone: This area is dedicated to your inventory of horseshoes, bar stock, pads, and other hoof care products. Efficient storage prevents damage to costly materials and ensures you always have the right supplies for the job.

Common mistakes to avoid are simply piling shoes in a bin, which leads to rust, damage, and difficulty finding specific sizes. Invest in proper shoe racks or divided bins that keep different sizes and types of shoes neatly separated and protected.

Consumables Zone: Nails, clips, bandages, medications, and other small, frequently used items need their own organized space. These are often stored in clear, labeled bins or small drawers to ensure quick identification and access.

Cleaning/Maintenance Zone: Don’t forget a dedicated spot for brushes, rags, cleaning supplies, and a small first aid kit. Maintaining a clean workspace isn’t just about appearance; it prevents dirt and debris from damaging your tools and equipment.

Office/Client Interaction Zone (Optional): Some farriers integrate a small space for paperwork, client invoicing, or even a laptop. This might be a small fold-down table or a dedicated drawer for a tablet and printer. It helps maintain a professional image and keeps your administrative tasks organized.

The overarching principle for layout is ergonomics. Think about how you move around your truck throughout the day. Place frequently used items within easy reach. Minimize bending, stretching, and repetitive movements that can lead to fatigue or injury over time. A logical flow saves countless steps throughout the day, significantly reducing physical strain.

Key Equipment and Storage Solutions for Optimal Farrier Truck Setup

Once your zones are defined, the next step is populating them with the right equipment and the most effective storage solutions. This is where your farrier truck organization truly comes to life.

Forging Equipment and Safety

Your portable forge is the heart of your hot work zone. Propane-fired forges are the most common due to their portability and ease of use. Ensure your propane tank is securely mounted, ideally externally, and properly vented. Your anvil should be mounted on a sturdy, stable stand that is at a comfortable working height. Many farriers opt for custom-built stands that integrate tool holders or a small shelf.

A quench tank, for cooling tools and shoes, needs to be positioned safely away from flammable materials but still within easy reach of the anvil. Based on my experience, a secure, heavy-duty fire extinguisher (ABC rated) is non-negotiable and should be mounted in a highly visible and accessible location, preferably near the forging area. It’s also wise to have a smaller one near the cab.

Hand Tools Storage: Precision and Protection

Your hand tools are your livelihood, and they deserve the best storage. Forget the generic toolbox where everything rattles around.

- Custom Toolboxes/Drawers: Many farriers opt for specialized drawers with custom-cut foam inserts for delicate tools like hoof knives, or dividers for nippers and clinchers. This not only keeps them organized but protects their edges and surfaces.

- Magnetic Tool Holders: Heavy-duty magnetic strips mounted on walls or inside compartment doors are excellent for holding hammers, rasps, and other frequently used metal tools within easy reach.

- Wall Mounts and Pegboards: For service bodies or van interiors, pegboards or specialized tool panels allow for vertical storage, keeping tools visible and accessible. Hooks, clips, and specialized holders can be arranged to suit your specific collection.

Power Tools and Electrical Solutions

Modern farriery often requires power tools, primarily grinders for shaping and finishing shoes.

- Grinders: Both corded and cordless grinders have their place. Corded grinders offer consistent power for heavy-duty tasks, requiring a generator or inverter. Cordless grinders provide unparalleled flexibility and convenience for quick touch-ups or when power is unavailable.

- Generators/Inverters: A reliable power source is critical. A portable generator can power corded tools and provide charging capabilities. If you opt for a van, a robust inverter system connected to a deep-cycle battery bank allows you to run tools silently without a generator, especially useful in quiet residential areas.

- Battery Charging Stations: If you rely on cordless tools, a dedicated charging station with multiple bays is essential to ensure your batteries are always topped up and ready for action.

Stock and Supply Storage: Efficiency in Inventory

Managing your inventory of shoes, pads, and other supplies efficiently saves time and prevents costly reordering mistakes.

- Shoe Racks: Custom-built or commercial shoe racks are invaluable. They keep different sizes and types of shoes neatly separated, preventing rust and damage. Many designs allow for easy viewing and selection.

- Divided Bins and Shelving: For nails, clips, pads, and various hoof care products, clear, stackable, and labeled bins are ideal. Shelving units, either fixed or pull-out, maximize vertical space in vans and service body compartments.

- Hoof Care Product Shelves: Products like sole packing, medicated wraps, and hoof dressings need secure, upright storage to prevent spills and damage.

Safety Gear Integration

Safety should be paramount in your farrier truck setup. Beyond the fire extinguisher, dedicate specific locations for personal protective equipment (PPE).

- Eye and Hearing Protection: Keep safety glasses and ear protection easily accessible, perhaps in a small compartment or on a hook near the entrance of your workspace.

- First Aid Kit: Common mistakes to avoid are forgetting a readily accessible, well-stocked first aid kit. It should be prominently displayed and clearly labeled, capable of handling minor cuts, burns, and other common workplace injuries. Regularly check and replenish its contents.

- Gloves and Aprons: Store your work gloves and farrier apron in a designated spot, allowing them to air out if needed, but always within easy reach.

Power and Lighting Solutions: Illuminating Your Work

Having reliable power and adequate lighting is crucial for both safety and efficiency, especially during early mornings, late evenings, or in poorly lit barns.

Generators: For many farriers, a portable generator is the primary power source for corded grinders, chargers, and other electrical equipment. When selecting a generator, consider its wattage output (ensure it can handle your tools’ peak loads), fuel type (gasoline or propane), and noise level. Quieter inverter generators are often preferred for their reduced noise and cleaner power output.

Inverters and Battery Banks: For those seeking a quieter, more integrated solution, particularly in a van setup, an inverter combined with a robust deep-cycle battery bank is an excellent option. The inverter converts DC battery power to AC power for your tools, allowing you to work silently without engine idling or generator noise. Charging the battery bank can be done via your vehicle’s alternator, solar panels, or shore power.

Solar Power (Emerging Trend): Solar panels mounted on the roof of your truck or van can provide a sustainable and silent way to charge your battery bank, reducing reliance on fuel-powered generators. While the initial investment can be higher, it offers long-term savings and environmental benefits.

Interior Lighting: Good interior lighting transforms your truck from a dark cave into a functional workspace. LED strip lights are highly energy-efficient and provide bright, even illumination throughout compartments and the main work area. Task lighting, such as flexible LED lamps, can be invaluable for detailed work at the anvil or workbench.

Exterior Work Lights: For working in dimly lit areas or during evening appointments, exterior floodlights mounted on your truck can illuminate your work area around the horse, ensuring safety and visibility. These are often LED for low power consumption and durability.

Organization and Customization Tips for Your Farrier Truck Setup

The difference between a good farrier truck setup and a great one often lies in the details of its organization and customization. Generic solutions rarely fit perfectly, so don’t be afraid to personalize your space.

Shelving Units: For vans and box trucks, heavy-duty shelving units are a must. You can opt for commercial shelving systems designed for work vehicles or build custom units from wood or aluminum. Ensure shelves have retaining lips or bungee cords to prevent items from falling out during transit.

Drawers and Bins: Deep, sturdy drawers are excellent for storing smaller tools, consumables, and hardware. Consider locking drawers for valuable items. Clear, stackable bins with labels are ideal for organizing nails, clips, and other small parts, allowing for quick visual inventory.

Magnetic Tool Holders: As mentioned, magnetic strips are fantastic for keeping frequently used metal tools visible and accessible. You can mount them on compartment doors, interior walls, or even near your anvil for quick tool changes.

Wall Panels (Pegboard, E-track): In a van or box truck, covering interior walls with pegboard or E-track systems provides immense flexibility. Pegboards allow you to hang tools and supplies using various hooks and clips, while E-track systems offer robust tie-down points for securing larger equipment or cargo.

Custom Built-Ins: Sometimes, the best solution is a custom-built unit tailored to your specific tools and workflow. This might include a specialized anvil stand with integrated drawers, a custom shoe rack that fits your exact inventory, or a dedicated cabinet for your hoof care products. Pro tip: Invest in custom solutions where standard options fall short, as they often pay for themselves in efficiency and longevity.

Security Measures: Your tools and equipment represent a significant investment. Robust locking systems for all compartments and vehicle doors are essential. Consider additional security measures like alarms or GPS trackers, especially for high-value equipment.

Maintenance and Longevity of Your Farrier Truck Setup

A well-designed mobile farrier workshop requires ongoing care to remain efficient and safe. Neglecting maintenance, both for your tools and your vehicle, can lead to costly downtime and premature replacement.

Regular Cleaning Schedule: Make it a habit to clean your truck regularly, perhaps at the end of each week. Remove dirt, debris, and hoof clippings. A clean workspace is more inviting and makes it easier to spot misplaced items or potential issues.

Tool Sharpening and Repair: Sharp tools are safe and efficient tools. Establish a routine for sharpening your knives and nippers. Repair or replace damaged tools promptly. A dull knife or a bent rasp not only makes your work harder but can also compromise the quality of your work and potentially injure the horse or yourself.

Vehicle Maintenance: Your truck is the backbone of your operation. Adhere to the manufacturer’s recommended service schedule for oil changes, tire rotations, brake inspections, and fluid checks. Based on my experience, neglecting your truck’s maintenance is a fast track to breakdowns and missed appointments, which directly impacts your income.

Rust Prevention: Farrier work often involves moisture and metal, a recipe for rust. Ensure your tools are dry before storage. Consider using rust-inhibiting liners in drawers and compartments. Regular cleaning and inspection can help you catch and address rust early.

Legal and Safety Considerations for Your Farrier Rig

Operating a professional farrier setup comes with legal and safety responsibilities that extend beyond the immediate work with horses.

Weight Limits and DOT Regulations: Be acutely aware of your vehicle’s Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Rating (GAWR). Overloading your truck is not only dangerous but can also lead to fines and insurance complications. If your business grows to include larger vehicles or you travel across state lines, you might need to comply with Department of Transportation (DOT) regulations.

Insurance: Ensure your vehicle insurance policy adequately covers your truck as a commercial vehicle and that your tools and equipment are covered under a separate commercial property or inland marine policy. Standard personal auto insurance will not suffice for a business vehicle and its contents.

Safe Handling of Propane/Gas: If you use a propane forge, proper storage and handling of propane tanks are critical. Always store tanks upright and secured, preferably in an external, well-ventilated location. Understand the risks of gas leaks and know how to safely shut off the supply.

Ergonomics for Injury Prevention: Farriery is physically demanding. Design your truck setup to minimize strain. Place heavy items lower, frequently used items within arm’s reach, and ensure adequate lighting to prevent eye strain. Consider anti-fatigue mats if you spend extended periods standing in your van. Safety should never be an afterthought; it should be integrated into every aspect of your design and daily routine.

Budgeting for Your Farrier Truck Setup

Setting up a truly professional farrier rig is a significant investment, but one that yields substantial returns in efficiency, professionalism, and longevity.

Initial Investment: This includes the cost of the base vehicle, the service body or internal shelving/customization, your forge, anvil, power tools, and hand tools. Prices can vary wildly depending on whether you buy new or used, and if you opt for DIY solutions versus professional installation.

Ongoing Costs: Factor in fuel, vehicle maintenance, tool sharpening and replacement, and the continuous replenishment of shoes, nails, and other supplies. A well-planned budget helps you manage these expenses effectively.

DIY vs. Professional Conversion: Doing much of the build-out yourself can save money on labor, but it requires time, skill, and access to tools. Professional conversions offer expertise, warranties, and often a faster turnaround, but at a higher cost. Weigh these factors carefully based on your resources and comfort level. Don’t underestimate the long-term value of a quality setup; shortcuts taken now can lead to costly repairs and inefficiencies later.

Conclusion: Your Mobile Farrier Workshop, Optimized

An expertly designed and meticulously organized farrier truck setup is more than just a convenience; it’s a strategic asset that underpins the success and professionalism of your farrier business. From the moment you choose your base vehicle to the intricate details of tool storage and power solutions, every decision contributes to your efficiency, safety, and ultimately, your reputation.

By implementing the principles and tips outlined in this comprehensive guide, you’re not just organizing tools; you’re streamlining your entire operation, reducing physical strain, and projecting an image of unparalleled professionalism to your clients. A well-oiled mobile farrier workshop allows you to focus on what you do best: providing exceptional hoof care.

We hope this deep dive has provided you with valuable insights to optimize your own farrier rig. Do you have any unique organization tips or custom solutions that have worked wonders for your setup? Share your experiences in the comments below!

For further reading on maintaining your tools, explore our article on Choosing the Best Farrier Tools and How to Care for Them (Internal Link 1). And if you’re looking to expand your business knowledge, check out our insights on Optimizing Your Farrier Business Operations for Growth (Internal Link 2). For more information on farrier safety standards and best practices, we recommend visiting the American Farriers Association website (External Link).