Powering Progress: Your Definitive Guide to Electric Fork Trucks For Sale

Powering Progress: Your Definitive Guide to Electric Fork Trucks For Sale Typestruck.Guidemechanic.com

The modern warehouse is a symphony of motion, precision, and efficiency. At its heart, the humble forklift plays a pivotal role, tirelessly moving goods, optimizing storage, and streamlining logistics. In today’s environmentally conscious and cost-aware world, the conversation increasingly shifts from traditional internal combustion (IC) models to their quieter, cleaner, and often more economical counterparts: electric fork trucks.

If you’re considering an upgrade, expanding your fleet, or simply exploring the future of material handling, you’ve come to the right place. This comprehensive guide will navigate the intricate landscape of electric fork trucks for sale, providing you with invaluable insights to make an informed decision. We’ll delve into their myriad benefits, the various types available, critical buying considerations, and expert tips to ensure your investment powers progress for years to come.

Powering Progress: Your Definitive Guide to Electric Fork Trucks For Sale

Why Go Electric? The Unbeatable Advantages of Electric Fork Trucks

The shift towards electric forklifts isn’t just a trend; it’s a strategic business decision driven by a compelling list of advantages. From environmental stewardship to significant operational savings, the benefits are clear and impactful. Based on my extensive experience in the material handling industry, opting for electric can truly revolutionize your operations.

1. Environmental Stewardship: Zero Emissions for a Cleaner Future

One of the most compelling reasons to choose an electric fork truck is its environmental footprint – or lack thereof. Unlike their diesel or propane-powered brethren, electric models produce zero tailpipe emissions. This means no harmful carbon monoxide, nitrogen oxides, or particulate matter are released into the atmosphere during operation.

This benefit is particularly crucial for indoor operations. Warehouses, distribution centers, and manufacturing facilities can maintain pristine air quality, protecting both workers and sensitive goods. Moving towards electric solutions aligns perfectly with corporate social responsibility goals and often meets increasingly stringent environmental regulations.

2. Significant Cost Savings: Beyond the Initial Price Tag

While the initial purchase price of an electric forklift might sometimes be comparable to or even slightly higher than an IC model, the long-term cost savings are substantial. Fuel costs are dramatically reduced, replaced by the much cheaper electricity required for charging. Furthermore, electric motors have fewer moving parts than internal combustion engines.

This mechanical simplicity translates directly into lower maintenance expenses. There are no oil changes, spark plugs, air filters, or complex transmission systems to service. Based on our experience, businesses often see a significant reduction in their annual maintenance budgets after transitioning to an electric fleet.

3. Operational Excellence: Quiet, Agile, and Efficient

Electric forklifts are renowned for their quiet operation. This reduction in noise pollution creates a more pleasant and safer working environment for operators and other personnel. Communication improves, and the risk of noise-induced fatigue or hearing damage is minimized.

Their design also often allows for greater maneuverability, especially in confined spaces. With smaller turning radii and precise control, electric models can navigate narrow aisles and tight corners with ease, optimizing warehouse layout and maximizing storage capacity. This agility directly contributes to enhanced operational efficiency.

4. Enhanced Safety and Operator Comfort

Safety is paramount in any material handling operation. Electric fork trucks contribute to a safer environment through their quiet nature, which allows operators to hear alarms or approaching personnel more easily. The absence of exhaust fumes also eliminates a significant health hazard, particularly in enclosed spaces.

Operators also benefit from reduced vibration and heat, leading to less fatigue over long shifts. Modern electric forklifts often feature advanced ergonomic designs, including comfortable seats, intuitive controls, and excellent visibility, further enhancing the operator experience and productivity.

Understanding the Different Types of Electric Fork Trucks Available

The term "electric fork truck" encompasses a diverse range of machines, each designed for specific tasks and environments. Choosing the right type is critical for maximizing efficiency and safety in your operation. Let’s explore the most common categories you’ll encounter when looking for electric fork trucks for sale.

1. Counterbalance Electric Forklifts

These are perhaps the most recognizable type of forklift, characterized by their weight counterbalance at the rear to offset the load being carried at the front. They are incredibly versatile and come in both 3-wheel and 4-wheel configurations.

- 3-Wheel Counterbalance: Highly maneuverable, ideal for tight spaces and narrow aisles. They excel in applications requiring frequent turning and precise positioning.

- 4-Wheel Counterbalance: Offers greater stability and higher load capacities, making them suitable for heavier loads and outdoor applications on smoother surfaces. They provide excellent traction and a more comfortable ride over longer distances.

2. Electric Reach Trucks

Designed specifically for high-density storage applications, reach trucks excel at lifting loads to impressive heights in very narrow aisles. They feature a mast that extends forward, allowing the forks to "reach" into racking without the entire truck having to enter the aisle.

Reach trucks are invaluable for maximizing vertical storage space in warehouses and distribution centers. They come in various configurations, including stand-up and sit-down models, offering flexibility based on operator preference and operational requirements.

3. Electric Pallet Jacks and Stackers

These are the workhorses for horizontal pallet movement and low-level lifting.

- Electric Pallet Jacks (Pallet Trucks): Primarily used for moving pallets horizontally across floors. They are essential for loading/unloading trucks and transporting goods over short to medium distances within a facility. Both walk-behind and ride-on versions are available.

- Electric Stackers: Similar to pallet jacks but with a mast that allows for lifting pallets to moderate heights, typically for stacking or retrieving goods from lower racking levels. They offer a cost-effective solution for vertical storage where a full-size forklift isn’t necessary or feasible.

4. Electric Order Pickers

Order pickers are designed to allow operators to manually pick individual items or cases from various racking levels. The operator platform lifts with the forks, providing direct access to products.

These trucks are indispensable in e-commerce fulfillment centers and retail distribution operations where accurate and efficient order fulfillment is paramount. They come in low-level, mid-level, and high-level configurations, depending on the required picking height.

5. Very Narrow Aisle (VNA) Trucks / Turret Trucks

For facilities with extremely narrow aisles, VNA trucks, also known as turret trucks or swing-mast trucks, are the ultimate solution. They can stack and retrieve pallets from either side of an aisle without turning the entire truck.

These specialized electric forklifts are designed for maximum storage density. While they require a higher initial investment and specialized training, the space savings they offer can be substantial, making them a wise choice for optimizing high-volume storage.

Key Factors to Consider When Buying Electric Fork Trucks

Purchasing an electric fork truck is a significant investment that requires careful consideration. To ensure you select the right equipment for your needs, you must evaluate several crucial factors. Based on our pro tips, a thorough assessment upfront will save you time, money, and headaches down the line.

1. Application and Operating Environment

Understanding where and how the forklift will be used is paramount.

- Load Capacity: What is the maximum weight you need to lift? Always factor in a safety margin.

- Lift Height: How high do you need to reach? Measure your highest racking levels.

- Aisle Width: This dictates the type of forklift you can use (e.g., counterbalance vs. reach truck vs. VNA).

- Operating Hours: Will the truck be used for a single shift, multiple shifts, or continuously? This impacts battery and charging requirements.

- Floor Conditions: Are your floors smooth concrete, uneven, or do they have inclines? This affects tire choice and overall truck stability.

- Indoor vs. Outdoor: While primarily designed for indoor use, some robust electric models can handle light outdoor work on paved surfaces.

2. Power Source and Battery Technology

The battery is the heart of an electric fork truck, and technology has advanced significantly.

- Lead-Acid Batteries: The traditional choice, known for their reliability and lower initial cost. They require regular watering and a dedicated charging area with ventilation. Charging cycles are typically 8 hours of charge, 8 hours of cool-down, and 8 hours of operation.

- Lithium-ion Batteries: A newer, increasingly popular option. They offer faster charging, opportunity charging (charging during breaks), longer lifespan, and are virtually maintenance-free (no watering). While they have a higher upfront cost, their efficiency and longevity often lead to a lower total cost of ownership over time.

Pro tips from us: Carefully evaluate your operational needs. If you run multiple shifts or need maximum uptime, lithium-ion might be the more economical choice despite the higher initial investment.

3. Ergonomics and Operator Comfort

A comfortable operator is a productive and safe operator. Look for features that enhance the user experience:

- Adjustable Seating and Controls: Allows customization for different operators.

- Visibility: Clear sightlines to the forks and surrounding area are critical for safety.

- Intuitive Controls: Easy-to-understand and operate levers, joysticks, and displays.

- Low Noise and Vibration: Reduces operator fatigue and improves communication.

4. Safety Features

Modern electric forklifts come equipped with a host of safety features designed to protect operators and pedestrians.

- Stability Control Systems: Help prevent tip-overs.

- Automatic Braking: Engages when the operator leaves the truck or during emergencies.

- Warning Lights and Alarms: Blue spotlights, strobe lights, and audible alarms enhance pedestrian awareness.

- Overload Protection: Prevents lifting loads beyond the truck’s rated capacity.

- Operator Presence Sensing System: Ensures the operator is properly seated before the truck can be driven.

5. Maintenance and Serviceability

Consider the ease of maintenance and the availability of parts and service.

- Accessibility: Can technicians easily access internal components for inspection and repair?

- Diagnostic Systems: Modern trucks often have onboard diagnostics that simplify troubleshooting.

- Dealer Network: Choose a dealer with a strong local presence, experienced technicians, and readily available spare parts. Reliable after-sales support is crucial for minimizing downtime.

6. Budget and Financing Options

Determine your budget early in the process. Consider whether you’re looking to purchase outright, lease, or rent.

- New vs. Used: Each has its pros and cons (discussed in the next section).

- Leasing: Can offer lower monthly payments and flexibility to upgrade to newer models periodically.

- Rental: Ideal for short-term needs, seasonal peaks, or when testing a specific model before purchase.

New vs. Used Electric Forklifts: Making the Right Choice

When looking for electric fork trucks for sale, you’ll inevitably face the decision between investing in a brand-new unit or opting for a pre-owned model. Both paths have distinct advantages and disadvantages that warrant careful consideration.

The Appeal of New Electric Forklifts

Purchasing a new electric forklift offers several compelling benefits. You’ll receive the latest technology, incorporating advancements in battery efficiency, ergonomic design, and safety features. A new truck comes with a full manufacturer’s warranty, providing peace of mind against unexpected repairs during the initial years of ownership.

New forklifts often offer a longer operational lifespan and tend to have lower maintenance costs in their early years. They can also be customized with specific attachments and features tailored precisely to your operational needs. The higher initial investment is often offset by improved productivity, reduced downtime, and the assurance of cutting-edge performance.

The Value of Used Electric Forklifts

Used electric forklifts present a cost-effective alternative, especially for businesses with tighter budgets or those that don’t require the absolute latest technology. The primary advantage is the significantly lower upfront purchase price, which can free up capital for other investments. Used trucks are often available immediately, avoiding the lead times associated with new equipment orders.

However, buying used requires a more diligent approach. Common mistakes to avoid are purchasing from an unreputable source or neglecting a thorough inspection. Pro tips from us: Always request detailed maintenance records, perform a comprehensive inspection by a qualified technician, and ideally, test drive the unit under typical operating conditions. Pay close attention to the battery’s health, as this is the most expensive component to replace in an electric forklift.

The True Cost of Ownership: Beyond the Sticker Price

The purchase price of an electric fork truck is just one piece of the financial puzzle. To truly understand your investment, you must consider the total cost of ownership (TCO) over the lifespan of the equipment. This holistic view provides a more accurate picture of the financial commitment.

Initial Purchase Price

This is the upfront cost of the forklift itself, including any selected options or attachments. This can vary widely based on the truck type, brand, capacity, and new vs. used status.

Battery and Charger Costs

For electric models, the battery and charger are significant components. While often included in the initial quote, their type (lead-acid vs. lithium-ion) and capacity will heavily influence the overall price. Replacement batteries can be a substantial expense down the line, so consider battery lifespan in your TCO calculations.

Maintenance and Repair

As discussed, electric forklifts generally have lower maintenance costs than IC trucks due to fewer moving parts. However, regular preventative maintenance is still crucial. Budget for routine inspections, lubrication, tire replacement, and potential repairs to electrical components or hydraulic systems. A good service plan with your dealer can help manage these costs.

Energy Consumption

The "fuel" for an electric forklift is electricity. Calculate your estimated electricity costs based on your local utility rates and the expected operating hours and charging cycles of the truck. While generally cheaper than fossil fuels, it’s still an ongoing expense.

Operator Training and Certification

Safety regulations mandate that forklift operators be properly trained and certified. Factor in the cost of initial training for new operators and ongoing refresher courses to maintain compliance and ensure safe operation.

Downtime Costs

Though harder to quantify, the cost of downtime due to breakdowns can be significant. This includes lost productivity, delayed shipments, and potential penalties. Investing in reliable equipment and a robust maintenance schedule helps minimize these often-overlooked expenses.

Battery Management: The Heart of Your Electric Forklift

The battery is undeniably the most critical component of an electric fork truck, directly impacting its performance, uptime, and overall lifespan. Proper battery management is not just a best practice; it’s essential for maximizing your investment.

Types of Batteries

- Lead-Acid Batteries: These are flooded batteries requiring regular watering with distilled water to maintain electrolyte levels. They are robust but demand a specific charging routine and cool-down period.

- Lithium-ion Batteries: A newer, more advanced option that is sealed, maintenance-free, and offers higher energy density. They do not require watering and can be opportunity charged, drastically improving uptime.

Proper Charging Practices

For lead-acid batteries, following the 8-hour charge, 8-hour cool-down, 8-hour operation rule is crucial. Overcharging or undercharging can severely reduce battery life. For lithium-ion, opportunity charging during breaks is highly beneficial, as it keeps the battery topped up and extends its overall cycle life.

Pro tips from us: Always use the charger specifically designed for your battery type and voltage. Mismatched chargers can damage batteries and pose safety risks.

Battery Room Setup and Safety

If using lead-acid batteries, a dedicated battery charging area is a must. This area requires proper ventilation to disperse hydrogen gas produced during charging, which can be explosive. Ensure eyewash stations, spill kits, and appropriate personal protective equipment (PPE) are readily available.

Common mistakes to avoid are charging batteries in unventilated areas, neglecting to check water levels, or allowing batteries to deep discharge frequently, which can cause irreversible damage.

Maintenance Tips for Longer Battery Life

For lead-acid batteries, regularly check electrolyte levels and add distilled water as needed (never tap water). Keep battery tops clean and dry to prevent corrosion. For both types, ensure battery connections are clean and secure. Regular inspection for any signs of damage or leakage is also vital. A well-maintained battery will perform better and last significantly longer.

Maximizing Efficiency and Safety with Your Electric Forklift Fleet

Acquiring the right electric fork trucks for sale is just the beginning. To truly unlock their potential, you need to implement strategies that optimize their operation, ensuring both maximum efficiency and paramount safety.

1. Operator Training and Certification

This cannot be stressed enough. Properly trained and certified operators are safer, more efficient, and cause less wear and tear on equipment. Training should cover not just the basics of operation but also specific safety protocols for electric trucks, proper battery handling, and daily inspection routines. Refresher training should be conducted regularly to reinforce best practices.

2. Regular Preventative Maintenance

A robust preventative maintenance schedule is key to maximizing uptime and extending the life of your electric forklifts. This includes routine checks of tires, brakes, hydraulics, electrical systems, and mast components. Proactive maintenance identifies potential issues before they escalate into costly breakdowns, minimizing unexpected downtime.

3. Fleet Management Systems

For larger fleets, consider investing in a fleet management system. These systems can track usage hours, impact events, battery charge levels, and maintenance schedules. This data provides invaluable insights into fleet performance, allowing for optimized scheduling, improved operator accountability, and more efficient maintenance planning.

4. Workplace Layout Optimization

The efficiency of your forklifts is also dependent on your facility’s layout. Ensure aisles are appropriately sized, clear of obstructions, and well-lit. Designated pedestrian walkways and traffic flow patterns enhance safety and streamline operations. Regular review and optimization of your warehouse layout can significantly boost productivity.

Where to Find Electric Fork Trucks For Sale

Once you’ve determined your specific needs, the next step is finding reputable sources for electric fork trucks for sale. The market offers several avenues, each with its own advantages.

1. Authorized Dealerships

This is often the most reliable option, especially for new equipment. Authorized dealers represent specific manufacturers (e.g., Toyota, Crown, Hyster, Yale). They offer:

- New Equipment: Access to the latest models, technology, and customization options.

- Certified Used Equipment: Often, dealers sell used forklifts that have been thoroughly inspected, reconditioned, and may come with a limited warranty.

- Expert Sales and Service: Knowledgeable sales staff, factory-trained technicians, and genuine parts availability.

- Financing and Leasing Options: They can often provide competitive financing or leasing packages.

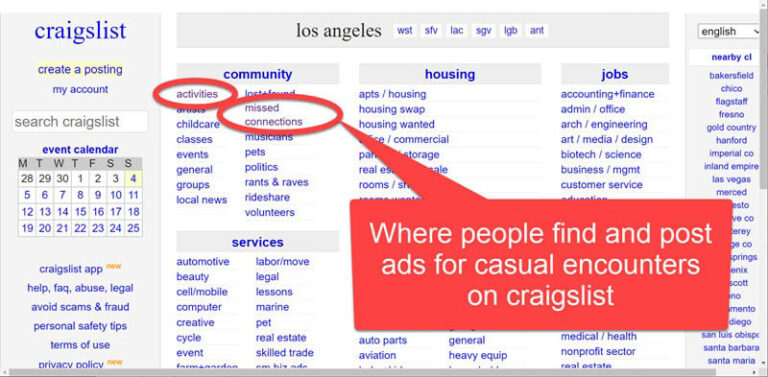

2. Online Marketplaces and Auction Sites

Platforms like eBay, Ritchie Bros., or specialized material handling equipment sites can offer a wide selection of used electric forklifts. While prices might be lower, the buyer assumes more risk.

Pro tips from us: If buying from an online marketplace, always arrange for a physical inspection by a qualified technician before finalizing a purchase. Be wary of deals that seem too good to be true.

3. Equipment Brokers

Brokers act as intermediaries, connecting buyers with sellers. They can be helpful for finding specific models or if you’re looking to offload old equipment. Ensure the broker is reputable and transparent about their fees and processes.

4. Direct from Manufacturers

While most manufacturers work through their dealer networks, some may offer direct sales for larger fleet orders or specialized equipment.

When evaluating potential suppliers, always inquire about their after-sales support, warranty terms, and the availability of parts and service in your region. A strong, responsive support network is just as important as the quality of the truck itself.

Pro Tips from an Expert: Ensuring a Smooth Purchase

Navigating the market for electric fork trucks for sale can be complex, but with the right approach, you can ensure a smooth and successful acquisition. Based on my experience, these expert tips will guide you through the process.

1. Thorough Research and Needs Assessment

Before you even start looking at models, conduct a detailed internal assessment. What are your exact operational requirements? What are your facility constraints? How many shifts? What’s your budget? The more precise you are with your needs, the better you can narrow down your options and avoid over- or under-specifying equipment.

2. Schedule Demonstrations and Test Drives

Never buy a forklift sight unseen or without a proper demonstration. Schedule a demo at your facility if possible, allowing your operators to test the machine in their actual working environment. This helps assess ergonomics, maneuverability, and overall suitability. It’s an invaluable step that reveals how the truck truly performs under your conditions.

3. Don’t Hesitate to Negotiate

The price listed isn’t always the final price. Be prepared to negotiate, especially if you’re purchasing multiple units or bundling in service contracts. Get quotes from several different dealers to compare not just prices, but also service agreements, warranties, and delivery terms.

4. Prioritize After-Sales Support and Warranty

A robust warranty and reliable after-sales support are crucial. Understand what the warranty covers and for how long. Inquire about response times for service calls, the availability of loaner equipment during major repairs, and the cost of preventative maintenance plans. A strong relationship with your dealer’s service department is an asset that minimizes downtime.

5. Consider the Total Cost of Ownership (TCO)

As previously discussed, look beyond the sticker price. Factor in battery costs, charger costs, expected maintenance, energy consumption, and operator training. Sometimes, a slightly more expensive truck upfront can be significantly cheaper over its operational lifespan due to lower running costs and higher efficiency. A trusted industry source like the Industrial Truck Association (ITA) often publishes resources on calculating TCO for different types of forklifts, which can be an excellent external reference.

Conclusion: Powering Your Future with Electric Fork Trucks

The decision to invest in electric fork trucks for sale is a forward-thinking one, offering a compelling blend of environmental responsibility, significant cost savings, and enhanced operational efficiency. By carefully evaluating your needs, understanding the diverse types available, and considering the total cost of ownership, you can make an informed choice that will benefit your business for years to come.

From quieter operations and cleaner air to reduced maintenance and energy bills, electric forklifts are transforming material handling. By applying the expert insights and practical advice shared in this comprehensive guide, you are well-equipped to navigate the market, select the ideal equipment, and power your operations towards a more productive, sustainable, and profitable future. Take the next step today and explore how electric fork trucks can elevate your business.