Navigating the Rails and Roads: Your Ultimate Guide to Finding Hi-Rail Trucks For Sale

Navigating the Rails and Roads: Your Ultimate Guide to Finding Hi-Rail Trucks For Sale Typestruck.Guidemechanic.com

The world of heavy equipment is vast and specialized, but few machines offer the unique versatility and critical functionality of a hi-rail truck. These remarkable vehicles, also known as road-rail vehicles, are indispensable for anyone working on or near railway lines, bridging the gap between conventional road transport and specialized rail operations. If you’re in the market for hi-rail trucks for sale, you’ve come to the right place.

This comprehensive guide is designed to be your definitive resource, offering unparalleled insights into understanding, evaluating, and ultimately purchasing the perfect hi-rail truck for your operational needs. Based on my extensive experience in the heavy equipment sector, we’ll delve deep into everything from their fundamental mechanics to crucial buying considerations, ensuring you make an informed decision that drives efficiency and safety for your projects.

Navigating the Rails and Roads: Your Ultimate Guide to Finding Hi-Rail Trucks For Sale

What Exactly Are Hi-Rail Trucks? The Dual-Purpose Powerhouse

At its core, a hi-rail truck is a standard road-going vehicle—typically a pickup, utility truck, or a medium-duty chassis—that has been specially modified with additional rail gear. This integrated system allows the truck to operate seamlessly on both conventional roads and railway tracks. It’s this dual functionality that makes them an invaluable asset for maintenance, construction, inspection, and emergency response along rail corridors.

The genius of hi-rail technology lies in its adaptability. Imagine needing to transport tools, personnel, or even specialized machinery directly to a remote section of track that’s miles from the nearest road access point. A standard truck can’t get there, and a dedicated railcar might be overkill or impractical. A hi-rail truck, however, can drive to the rail crossing, deploy its rail wheels, and smoothly transition onto the tracks, providing unparalleled access and efficiency.

Understanding the Rail Gear Mechanism

The "hi-rail" component refers to the retractable steel or aluminum wheels, known as rail gear, mounted at both the front and rear of the truck. When the truck needs to operate on rails, these guide wheels are lowered, lifting the truck’s road wheels slightly above the track surface, allowing the vehicle to be guided by the rails. The truck’s regular tires still maintain contact with the rail, providing the necessary traction and braking power.

This innovative design ensures stability and control while on the tracks, yet allows for rapid deployment and retrieval. The transition from road to rail and back is typically a quick and straightforward process, making these trucks incredibly efficient for dynamic work environments where time is often of the essence. It’s a testament to engineering ingenuity, blending two distinct modes of transport into one highly functional unit.

Why Invest in a Hi-Rail Truck? The Unmatched Advantages

The decision to invest in hi-rail trucks for sale is often driven by a clear need for operational efficiency and enhanced safety in rail-related work. These specialized vehicles offer a suite of benefits that traditional equipment simply cannot match. From project managers to field technicians, the advantages are clear and impactful across various industries.

Versatility and Efficiency

One of the most compelling reasons to choose a hi-rail truck is its inherent versatility. These trucks eliminate the need for multiple pieces of equipment or complex logistical planning when projects span both road and rail environments. They can transport crews and equipment directly to the job site, whether it’s adjacent to a highway or deep within a rail network, drastically reducing travel time and improving response capabilities.

This efficiency translates into significant time and cost savings. Instead of offloading equipment at a rail siding and then transferring it to a rail-bound vehicle, a hi-rail truck offers a continuous journey. This streamlined workflow minimizes downtime and maximizes productivity, making every hour on the job count more effectively.

Safety on the Tracks

Safety is paramount when working around railway lines, and hi-rail trucks are designed with this in mind. By allowing personnel and equipment to be transported safely along the tracks, they reduce the risks associated with manual handling and walking along active rail corridors. Modern rail gear systems often include advanced safety features, such as emergency braking, positive rail contact indication, and integrated lighting packages.

Furthermore, these vehicles provide a stable and controlled platform for operations like track inspection, repairs, and signal maintenance. Operators are typically trained specifically for hi-rail operations, adhering to strict safety protocols that further mitigate potential hazards. Based on my experience, investing in properly maintained and certified hi-rail equipment is a non-negotiable step for any rail-adjacent operation focused on worker safety.

Cost-Effectiveness in Operations

While the initial investment in hi-rail trucks for sale can be substantial, the long-term cost savings often outweigh the upfront expenditure. By consolidating transport and operational functions into a single vehicle, companies can reduce fuel consumption, labor costs, and the need for separate rail and road fleets. Maintenance can also be more centralized, as many components are standard truck parts.

The ability to quickly respond to emergencies or undertake preventative maintenance without the logistical hurdles of conventional rail equipment also prevents costly delays and potential service disruptions. For example, a rapid response hi-rail unit can address a track issue far faster than a dedicated rail crew mobilized from a distant yard, preventing potential train delays or even accidents.

Access to Remote Locations

Many railway lines traverse remote, challenging terrain where road access is limited or non-existent. Hi-rail trucks are the perfect solution for reaching these isolated sections. Whether it’s inspecting bridges over deep ravines, repairing signaling equipment in dense forests, or performing track maintenance far from urban centers, these vehicles provide essential mobility.

This unparalleled access ensures that critical infrastructure can be maintained and inspected regularly, regardless of its location. It empowers teams to perform their duties efficiently and effectively, even in the most inaccessible environments, which is vital for the integrity and safety of the entire rail network.

Types of Hi-Rail Trucks: Finding Your Perfect Match

Just as there are diverse jobs on the railway, there are various configurations of hi-rail trucks for sale, each tailored to specific tasks. Understanding these types is crucial for selecting a vehicle that perfectly aligns with your operational requirements. Choosing the wrong configuration can lead to inefficiencies or even safety concerns.

Service and Utility Hi-Rail Trucks

These are perhaps the most common type of hi-rail truck, built on a standard pickup or utility truck chassis. They are typically equipped with service bodies that offer ample storage for tools, parts, and small equipment. Utility hi-rail trucks are ideal for track inspection, signal maintenance, minor repairs, and transporting small crews.

Their agility and smaller footprint make them perfect for rapid response and accessing tighter spaces. They are often seen with integrated generators, air compressors, and welding equipment, turning them into mobile workshops capable of handling a wide range of tasks directly on the tracks.

Crane-Equipped Hi-Rail Trucks

For tasks requiring heavy lifting, crane-equipped hi-rail trucks are indispensable. These vehicles combine the mobility of a hi-rail system with the power of a hydraulic crane, mounted on a medium to heavy-duty truck chassis. They are used for setting poles, loading and unloading materials, replacing rail sections, and assisting with accident recovery.

The crane’s reach and lifting capacity are critical considerations, as is the truck’s overall stability when operating the crane on rails. These trucks represent a significant investment but offer immense capability for demanding construction and maintenance projects along the rail line.

Personnel Carrier Hi-Rail Trucks

When the primary need is to transport a larger crew safely and efficiently, personnel carrier hi-rail trucks are the answer. These can range from extended cab pickups to specialized passenger vans or buses modified with rail gear. They ensure that an entire team can travel together to a worksite, carrying their personal gear and some tools.

These trucks often prioritize passenger comfort and safety, with features like enhanced climate control and communication systems. They are crucial for large-scale maintenance projects, track laying crews, or any situation where multiple workers need to be moved along the rail corridor.

Specialized Hi-Rail Applications

Beyond these common types, the market also offers highly specialized hi-rail trucks. This can include dump trucks for material transport, excavators mounted on rail gear for track work, or even water trucks for dust suppression or fire fighting along rail lines. The adaptability of hi-rail technology means that almost any truck-based application can be converted for rail use.

These specialized units are often custom-built or heavily modified to meet very specific industry needs, showcasing the incredible flexibility of hi-rail systems. When searching for hi-rail trucks for sale, it’s important to think creatively about how these specialized units could benefit your unique operations.

Navigating the Market: Where to Find Hi-Rail Trucks For Sale

Finding the right hi-rail truck requires knowing where to look. The market for these specialized vehicles can be diverse, with options ranging from brand-new models to well-maintained used equipment. Based on my experience, a multi-pronged approach usually yields the best results.

Authorized Dealerships

For new hi-rail trucks for sale, authorized dealerships specializing in heavy equipment and truck upfitting are your primary go-to. These dealers work directly with manufacturers of both the base truck chassis and the rail gear systems. They can offer brand-new units with full factory warranties, the latest technology, and customization options tailored to your exact specifications.

Purchasing from an authorized dealer often comes with the benefit of comprehensive after-sales support, including certified service technicians and genuine replacement parts. While typically a higher investment, the peace of mind and long-term support can be invaluable, especially for critical infrastructure work.

Used Equipment Specialists

Many businesses find excellent value in the used hi-rail truck market. Specialized used equipment dealers often have a rotating inventory of pre-owned units from various manufacturers. These dealers typically inspect and service the trucks before sale, offering a more affordable entry point without sacrificing too much on quality.

When dealing with used equipment specialists, always inquire about their inspection process, any reconditioning work performed, and if they offer any limited warranties. Pro tips from us: a reputable dealer will be transparent about the vehicle’s history and condition.

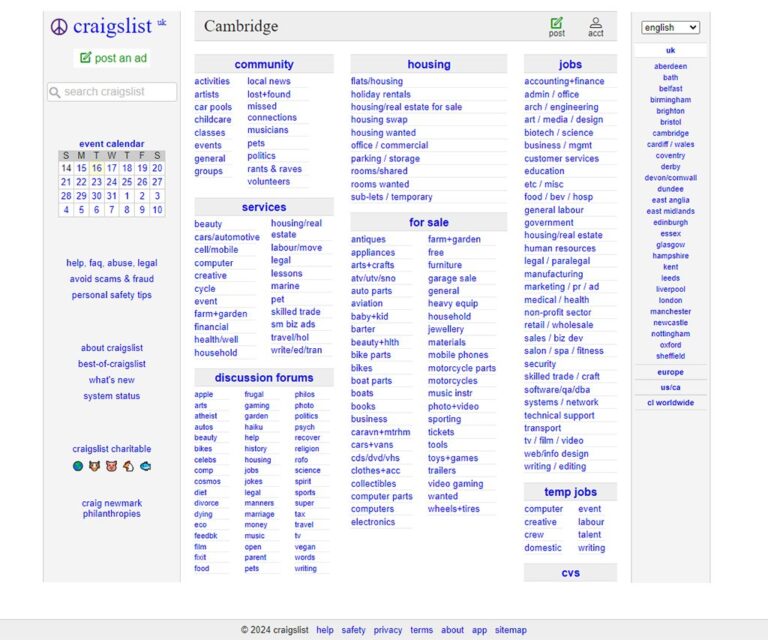

Online Marketplaces and Auctions

The digital age has opened up numerous avenues for finding hi-rail trucks for sale. Websites dedicated to heavy equipment sales, general online classifieds, and specialized auction platforms frequently list hi-rail units. These platforms can offer a wide geographical reach and competitive pricing, especially at auctions.

However, caution is advised when buying from online marketplaces or auctions. While prices can be attractive, the level of inspection and guarantees might be minimal. It’s absolutely critical to arrange for a thorough third-party inspection before committing to a purchase from these sources.

Direct from Contractors/Companies

Sometimes, businesses upgrade their fleets or downsize, selling their existing hi-rail trucks directly. This can be a great way to find well-maintained equipment that has been actively used in the field. These sales might be advertised through industry networks, professional associations, or even word-of-mouth.

The benefit here is often a direct line to the vehicle’s operational history and maintenance records. You might even be able to speak directly with the previous operators. However, be prepared to handle the transaction and logistical details yourself, as these sellers typically don’t offer the same level of support as a dealer.

Key Considerations When Buying a Hi-Rail Truck

Purchasing a hi-rail truck is a significant investment, and a thorough evaluation process is essential to ensure you acquire a reliable and suitable asset. Based on my extensive experience, there are several critical factors that buyers often overlook, leading to costly mistakes down the line. Let’s break down the most important considerations.

Condition of the Base Truck: Engine, Transmission, Chassis

While the rail gear is what makes it "hi-rail," the foundation is still a conventional truck. The condition of the base vehicle’s engine, transmission, and chassis is paramount. A robust engine is necessary to handle the weight of the rail gear and any mounted equipment, as well as to provide ample power for on-track operations.

Thoroughly inspect for signs of excessive wear, leaks, or rust, particularly on the chassis where the rail gear is mounted. Check the mileage and engine hours, as these can give you a good indication of the overall lifespan and remaining service life of the vehicle. A well-maintained base truck ensures reliability on both road and rail.

Condition of the Rail Gear: Type, Wear, Maintenance History

The rail gear itself is arguably the most critical component. Investigate the type of rail gear installed (e.g., brand, model) and its suitability for your intended track type and weight requirements. Look for signs of excessive wear on the rail wheels, bearings, and hydraulic components. Cracks, bends, or significant corrosion are major red flags.

It’s also crucial to review the maintenance history of the rail gear specifically. Unlike a regular truck, rail gear requires specialized inspections and servicing. Ask about the last time it was certified or underwent a major service. Common mistakes to avoid are assuming the rail gear is in good condition just because the truck looks good.

Certification and Compliance: FRA, DOT, Local Regulations

This is a non-negotiable item. Any hi-rail truck operating on active railway lines in the United States must be certified by the Federal Railroad Administration (FRA) or an equivalent governing body in other countries. Ensure the truck comes with valid and current certification documentation. Without it, you cannot legally operate on most rail networks.

Beyond FRA, consider any specific Department of Transportation (DOT) requirements for road use and any local or company-specific safety standards. Pro tips from us: always verify the certification numbers and dates with the relevant authorities. You can find comprehensive information on FRA standards on their official website.

Maintenance Records and Service History: A Non-Negotiable Item

A detailed maintenance log is a window into the truck’s past and an indicator of its future reliability. Request comprehensive service records for both the base truck and the rail gear. Look for consistent servicing, records of major repairs, and regular inspections. Gaps in the maintenance history or a complete lack of records should raise serious concerns.

A well-documented history suggests responsible ownership and proactive maintenance, which significantly reduces the risk of unexpected breakdowns and costly repairs after purchase. This is where showing experience (E-E-A-T) really comes into play – a seller with good records is often a more trustworthy seller.

Payload Capacity and Application Suitability: Matching Needs to Equipment

Consider what you intend to carry and what tasks the truck will perform. Does it need to transport heavy tools, a large crew, or operate specialized attachments like cranes or welders? Ensure the truck’s gross vehicle weight rating (GVWR) and the rail gear’s capacity are sufficient for your heaviest anticipated loads.

Overloading a hi-rail truck can compromise safety, accelerate wear, and lead to regulatory non-compliance. Clearly define your operational needs before you start looking for hi-rail trucks for sale to avoid purchasing an underpowered or undersized unit.

Inspection: Don’t Skip This Step!

Even if you’re knowledgeable about heavy equipment, a professional, independent third-party inspection is highly recommended. This inspector should be familiar with hi-rail systems and their specific compliance requirements. They can identify hidden issues, assess the true condition of both the truck and the rail gear, and provide an unbiased report.

This investment in a professional inspection can save you tens of thousands of dollars in unforeseen repairs and prevent you from purchasing a non-compliant or unsafe vehicle. It’s one of the most important pro tips we can offer.

Warranty and After-Sales Support: What to Expect

For new hi-rail trucks, inquire about the manufacturer’s warranty for both the chassis and the rail gear. For used trucks, some reputable dealers may offer limited warranties. Understand what is covered, for how long, and what the claims process entails.

Additionally, consider the availability of parts and service support. Can you easily get replacement components for the rail gear? Is there a qualified service center nearby? Good after-sales support ensures your investment remains operational and minimizes downtime.

New vs. Used Hi-Rail Trucks: Making the Right Choice

The decision between purchasing a new or used hi-rail truck is a fundamental one, often dictated by budget, immediate needs, and long-term operational strategy. Each option presents its own set of advantages and disadvantages.

The Appeal of New Hi-Rail Trucks

Opting for a new hi-rail truck means you’re getting the latest technology, often with enhanced safety features, improved fuel efficiency, and greater reliability right off the lot. New trucks come with full manufacturer warranties, providing peace of mind against unexpected defects or breakdowns. You also have the flexibility to customize the truck and rail gear to your exact specifications, ensuring it perfectly meets your operational demands from day one.

While the initial cost is higher, the lower maintenance requirements in the early years and the guaranteed compliance with current regulations can offer significant long-term value. This option is ideal for companies seeking predictable operating costs and cutting-edge performance.

The Value Proposition of Used Hi-Rail Trucks

Used hi-rail trucks for sale offer a compelling alternative for budget-conscious buyers or those with less frequent operational needs. The primary advantage is the significantly lower upfront cost, allowing businesses to acquire essential equipment without a massive capital outlay. A well-maintained used hi-rail truck can provide years of reliable service, delivering excellent return on investment.

However, the used market requires more diligent inspection and research. While you might save on the purchase price, be prepared for potentially higher maintenance costs or the need for immediate repairs to bring the vehicle up to your operational standards.

Pro Tips for Evaluating Used Equipment

When considering used hi-rail trucks for sale, always insist on a comprehensive inspection by a qualified mechanic specializing in both heavy trucks and rail gear. Verify all certifications, particularly FRA compliance, and scrutinize maintenance records for any red flags. Check for signs of rust, wear on critical components, and the overall condition of the cab and utility body.

It’s also wise to consider the availability of spare parts for older models, especially for specialized rail gear components. A thorough evaluation process can help you uncover hidden gems and avoid potential money pits.

Financing Your Hi-Rail Truck Purchase

Acquiring hi-rail trucks for sale often involves a substantial investment, making financing a crucial aspect of the purchasing process. Understanding your options can help you secure the equipment you need while managing your capital effectively.

Traditional Loans

Many businesses opt for traditional equipment loans from banks or credit unions. These loans typically involve a down payment, fixed monthly payments, and a set interest rate over a specific term. This approach allows you to own the asset outright once the loan is repaid and can be a good option for companies with strong credit and predictable cash flow.

The terms and interest rates will vary based on your financial standing and the current market, so it’s wise to shop around and compare offers from multiple lenders.

Leasing Options

Leasing is an increasingly popular option for heavy equipment, including hi-rail trucks. Instead of purchasing, you essentially rent the equipment for a set period, with lower monthly payments compared to a loan. At the end of the lease term, you may have the option to purchase the truck, return it, or upgrade to a newer model.

Leasing can offer significant tax advantages and allows for more frequent equipment upgrades, which is beneficial if technology is rapidly evolving or your project needs change often. It’s an excellent way to acquire new equipment with less upfront capital.

Specialized Equipment Financing

Beyond traditional banks, there are specialized lenders who focus specifically on heavy equipment financing. These lenders often have a deeper understanding of the industry, the equipment’s value, and the unique needs of businesses operating in sectors that utilize hi-rail trucks. They might offer more flexible terms or tailored solutions that banks cannot.

Exploring these specialized options can sometimes yield more favorable rates or terms, especially if your business has unique financial circumstances or is relatively new.

Maintenance Matters: Protecting Your Investment

Once you’ve secured your hi-rail truck, effective maintenance becomes paramount. Proper care not only extends the lifespan of your vehicle but also ensures safe and compliant operation, which is critical for all rail-related work. Based on my experience, neglecting routine maintenance is one of the quickest ways to erode the value and reliability of your hi-rail asset.

Regular Rail Gear Inspections

The rail gear is subjected to immense stress and wear. It requires more frequent and specialized inspections than the base truck components. Regularly check for:

- Wheel wear: Look for flat spots, cracks, or excessive thinning of the wheel flanges.

- Bearing condition: Listen for unusual noises and check for excessive play.

- Hydraulic system: Inspect hoses, cylinders, and connections for leaks or damage.

- Mounting hardware: Ensure all bolts and fasteners are tight and free from corrosion.

These inspections should be performed before each shift and by a qualified technician at regular intervals, adhering strictly to manufacturer guidelines and FRA requirements.

Standard Truck Maintenance Schedules

While the rail gear is unique, the base truck still requires all the standard maintenance of a conventional heavy-duty vehicle. This includes:

- Engine oil and filter changes: Follow manufacturer-recommended intervals based on mileage and operating hours.

- Transmission and differential fluid checks: Ensure proper levels and condition.

- Brake system inspection: Crucial for both road and rail safety.

- Tire checks: For proper inflation, wear, and damage.

- Electrical system checks: Especially for lights, signals, and any auxiliary equipment.

Consistent adherence to these schedules will prevent premature wear, improve fuel efficiency, and ensure the truck is always ready for service.

Operator Training and Safety Protocols

Maintenance isn’t just about the mechanics; it’s also about the human element. Proper operator training is a critical component of maintaining your hi-rail truck and ensuring safety. Operators must be fully trained on the safe operation of both the truck and the rail gear, including deployment, retrieval, on-track procedures, and emergency protocols.

Establishing clear safety protocols for track access, communication with rail authorities, and daily pre-operational checks will significantly reduce the risk of accidents and equipment damage. A well-trained operator is often the first line of defense against potential issues.

Common Mistakes to Avoid When Buying a Hi-Rail Truck

As an expert in the field, I’ve witnessed common pitfalls that buyers encounter when searching for hi-rail trucks for sale. Being aware of these can save you considerable time, money, and frustration.

Overlooking Rail Gear Certification

One of the most critical and frequently overlooked aspects is ensuring the rail gear is properly certified and compliant with all relevant regulations, especially FRA standards. Buying a truck without valid certification means it cannot legally operate on most railway networks, rendering your investment useless. Always ask for current documentation and verify its authenticity.

Skipping a Professional Inspection

The temptation to save money by forgoing a professional third-party inspection is a common mistake. However, a superficial look can miss critical issues with the engine, transmission, or, most importantly, the rail gear. An expert inspector can identify potential safety hazards or impending mechanical failures that could cost you far more in repairs down the line.

Ignoring Maintenance History

A lack of detailed maintenance records is a significant red flag. Without a clear service history, you have no way of knowing how well the truck has been cared for, what repairs have been made, or when the last major service occurred. This uncertainty significantly increases the risk of purchasing a truck with hidden problems that could lead to costly downtime.

Not Matching the Truck to the Task

Purchasing a hi-rail truck that is either too small or too large for your primary operational needs is another common error. An undersized truck will be overworked and wear out quickly, while an oversized one is an unnecessary capital expense and can be less agile. Carefully assess your required payload, crew size, and the types of tasks you’ll perform before making a decision.

Future Trends in Hi-Rail Technology

The world of hi-rail trucks is continuously evolving. We’re seeing advancements in automation, improved telematics for remote monitoring and diagnostics, and electric or hybrid powertrain options emerging. These innovations promise even greater efficiency, reduced environmental impact, and enhanced safety features for the next generation of hi-rail trucks for sale. Staying abreast of these trends can help you make future-proof decisions.

Conclusion: Your Path to a Smart Hi-Rail Truck Purchase

Navigating the market for hi-rail trucks for sale can seem daunting, but with the right knowledge and a systematic approach, you can make a strategic investment that significantly boosts your operational efficiency and safety. From understanding the core mechanics and diverse types of hi-rail vehicles to meticulously evaluating their condition, certification, and maintenance history, every step is crucial.

Remember to prioritize safety, always seek professional inspections, and never compromise on compliance. By considering new versus used options and exploring smart financing solutions, you can acquire a hi-rail truck that perfectly aligns with your project demands and budget. This isn’t just about buying a vehicle; it’s about investing in a versatile, powerful tool that will drive your rail-related projects forward with confidence and unparalleled capability.