Navigating the Market: Your Ultimate Guide to Finding Diesel Tanker Trucks For Sale

Navigating the Market: Your Ultimate Guide to Finding Diesel Tanker Trucks For Sale Typestruck.Guidemechanic.com

The logistics and energy sectors are the lifeblood of our modern economy, and at their core are the heavy-duty vehicles that transport essential resources. Among these, the diesel tanker truck stands out as a critical asset, moving everything from fuel to industrial chemicals, ensuring industries run smoothly and communities receive their vital supplies. If you’re looking for Diesel Tanker Trucks For Sale, whether to expand your fleet, start a new venture, or replace an aging asset, you’re embarking on a significant investment that requires thorough understanding and careful consideration.

This comprehensive guide is designed to be your definitive resource. We’ll delve deep into every aspect of acquiring a diesel tanker truck, offering insights, expert tips, and a roadmap to help you make an informed decision. Our goal is to equip you with the knowledge to not just find a truck, but to find the right truck that delivers exceptional value and performance for years to come.

Navigating the Market: Your Ultimate Guide to Finding Diesel Tanker Trucks For Sale

Why Invest in a Diesel Tanker Truck? Understanding the Market Demand

The decision to purchase a diesel tanker truck is often driven by robust and consistent market demand. These specialized vehicles are indispensable across a multitude of industries, forming a critical link in the supply chain for various liquid commodities. Understanding this demand helps underscore the value of such an investment.

Based on my experience in the commercial trucking sector, the demand for reliable liquid transportation remains perpetually high. Every industry that relies on petroleum products, water, or specific chemicals needs a way to move these liquids safely and efficiently. This creates a stable and often lucrative operational environment for tanker truck owners and operators.

For instance, the fuel distribution sector alone presents a massive market. Gas stations, industrial sites, construction projects, and even agricultural operations all require regular deliveries of diesel, gasoline, and other petroleum products. A well-maintained diesel tanker truck directly addresses this ongoing need, ensuring a steady stream of business opportunities.

Furthermore, these trucks are versatile. While the primary focus might be on diesel, many tankers are designed or can be adapted to transport other liquid materials, expanding their operational scope. This adaptability enhances their long-term earning potential and resilience in a fluctuating market.

Key Considerations Before Buying: A Comprehensive Checklist

Acquiring a diesel tanker truck is a complex process, far more involved than simply picking a model. There are numerous factors to weigh, each impacting the truck’s suitability, operational costs, and regulatory compliance. A thorough checklist ensures you cover all bases before making a commitment.

1. New vs. Used Diesel Tanker Trucks: Pros and Cons

One of the first significant decisions you’ll face is whether to purchase a new or used tanker truck. Both options have distinct advantages and disadvantages that can significantly influence your budget and long-term operational strategy.

New Diesel Tanker Trucks:

- Pros: Offer the latest technology, superior fuel efficiency, full manufacturer warranties, and customization options. You get peace of mind knowing the vehicle has no prior operational history.

- Cons: Significantly higher upfront cost, which can be a barrier for smaller businesses or those with limited capital. Depreciation is also steepest in the first few years.

Used Diesel Tanker Trucks:

- Pros: Much lower purchase price, making them more accessible. Depreciation has already occurred, offering better value retention. A wider variety of models and configurations might be available immediately.

- Cons: Potential for higher maintenance costs due to wear and tear, limited or no warranty, and the need for thorough inspections to uncover hidden issues. You might also miss out on the latest technological advancements.

Pro tips from us: If budget is a primary concern and you have access to a skilled maintenance team, a well-inspected used diesel tanker truck can offer excellent value. However, for long-term fleet expansion and reduced operational headaches, a new truck, if affordable, provides unparalleled reliability. Common mistakes to avoid are underestimating potential repair costs for older used trucks or overstretching your budget for a new one without a clear return on investment strategy.

2. Tanker Type and Capacity: Matching Needs to Specifications

The specific type of liquid you intend to transport, and the volume required, are fundamental in determining the right tanker specifications. "Diesel" might seem straightforward, but petroleum tankers have unique requirements.

For transporting diesel and other petroleum products, you’ll typically look for a petroleum tanker. These are designed to safely handle flammable liquids, often featuring multiple compartments. This compartmentalization is crucial, allowing you to carry different grades of fuel or smaller quantities to various destinations without mixing.

Consider the capacity in gallons or liters that best suits your typical routes and customer demands. Over-specifying capacity can lead to unnecessary weight and reduced fuel efficiency when not fully loaded, while under-specifying can lead to inefficient multiple trips. Accurately assessing your average load size is key to optimizing your investment.

3. Chassis and Engine Specifications: The Backbone of Your Operation

The chassis and engine form the core mechanical system of your tanker truck, dictating its performance, reliability, and operational lifespan. Choosing wisely here is paramount.

Look for a robust chassis built to handle the substantial weight of a fully loaded tank. Key considerations include the engine’s horsepower and torque, which must be adequate for your intended routes, including any inclines or challenging terrains. The transmission type (manual vs. automatic) and the axle configuration (e.g., 6×4 for heavy hauling) also play significant roles in drivability and load distribution.

Reputable chassis manufacturers like Freightliner, Kenworth, Peterbilt, Volvo, and Mack are known for their durability and extensive dealer networks. For used diesel tanker trucks, a comprehensive maintenance history is invaluable. It provides insights into how well the engine and chassis have been cared for, helping predict future reliability.

4. Material of Construction: Durability Meets Specificity

The material used for the tank’s construction is critical, influencing its weight, durability, and suitability for specific cargo. While "diesel" is the primary focus, understanding material properties is still vital.

Aluminum tanks are popular for petroleum products due to their lighter weight, which allows for greater payload capacity. They are also resistant to corrosion from many petroleum-based liquids.

Steel tanks (carbon steel) are robust and cost-effective but heavier. They are often used for general-purpose liquids, but can also handle diesel.

Stainless steel tanks offer superior corrosion resistance and are often chosen for chemicals, food-grade liquids, or where purity is paramount. While possibly overkill for standard diesel, some multi-purpose tankers might feature stainless steel.

Your choice impacts not only the truck’s tare weight and fuel efficiency but also its long-term resistance to wear and tear from the transported product.

5. Safety Features and Regulations Compliance (DOT, HAZMAT): Non-Negotiable Essentials

Safety is paramount when transporting flammable liquids like diesel. Adherence to regulatory standards is not just about avoiding fines; it’s about protecting lives, property, and the environment.

Ensure the tanker truck you consider meets all relevant Department of Transportation (DOT) regulations in your jurisdiction, as well as specific Hazardous Materials (HAZMAT) guidelines. This includes proper labeling, placarding, and vehicle design standards. Key safety features to look for include:

- Anti-lock Braking Systems (ABS) and Electronic Stability Control (ESC).

- Emergency shut-off valves for immediate cargo containment.

- Vapor recovery systems to minimize emissions during loading and unloading.

- Overfill protection systems to prevent spills.

- Roll stability systems to prevent rollovers, especially critical for high center-of-gravity tanks.

External Link: For detailed information on HAZMAT regulations and transportation safety, refer to official resources like the U.S. Department of Transportation Pipeline and Hazardous Materials Safety Administration (PHMSA) at www.phmsa.dot.gov. Staying compliant is not just a legal obligation but a cornerstone of responsible operation.

6. Pump and Metering Systems: Precision and Efficiency

The efficiency and accuracy of your loading and unloading operations largely depend on the quality of the pump and metering systems. These components are essential for precise delivery and billing.

Look for reliable pumps capable of achieving desired flow rates, which will impact your delivery times. The metering system, often a positive displacement meter, must be accurate and regularly calibrated to ensure precise measurement of delivered product. This accuracy is vital for maintaining customer trust and ensuring correct invoicing. Features like electronic registers and ticket printers can streamline your operations and record-keeping.

Where to Find Diesel Tanker Trucks For Sale: Your Sourcing Guide

Locating the right diesel tanker truck requires knowing where to look. The market is diverse, offering various avenues to explore, each with its own set of advantages and considerations.

From my extensive work in the industry, I’ve seen successful acquisitions come from a mix of traditional and digital channels. The key is to cast a wide net while maintaining a sharp focus on quality and verification.

1. Dealerships (New & Used)

Commercial truck dealerships are often the first stop for many buyers. They offer a structured buying experience, often with financing options and extended warranties, especially for new vehicles.

- New Truck Dealerships: Ideal for those seeking the latest models, full customization, and manufacturer support. They typically have knowledgeable sales staff who can guide you through specifications.

- Used Truck Dealerships: Many dealerships also carry a selection of used diesel tanker trucks. These often come with some level of inspection and reconditioning, providing a layer of confidence beyond private sales.

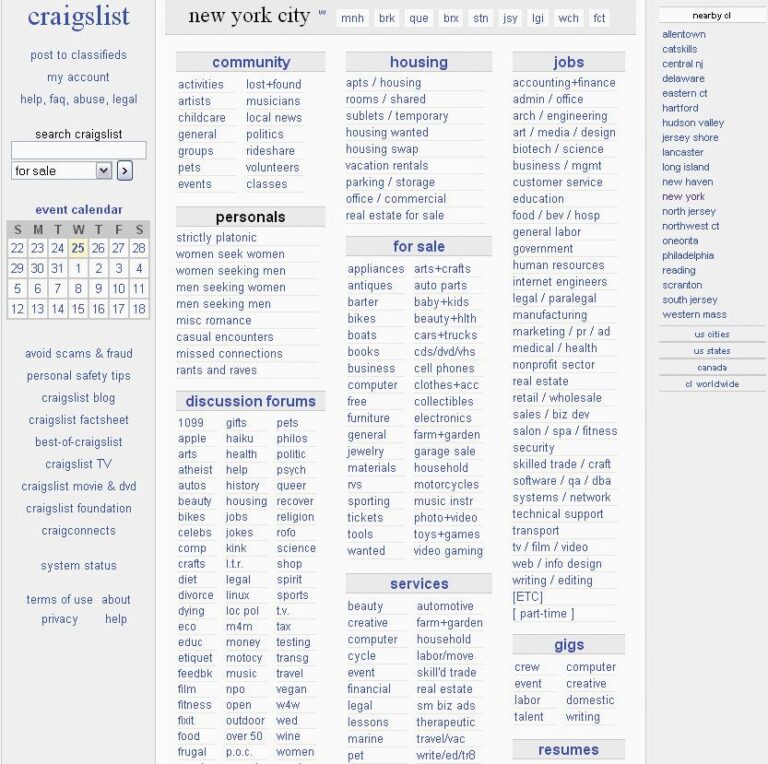

2. Online Marketplaces & Auction Sites

The internet has revolutionized how commercial vehicles are bought and sold. Online platforms offer unparalleled reach and variety.

- Dedicated Commercial Truck Sites: Websites like TruckPaper.com, CommercialTruckTrader.com, and MyLittleSalesman.com specialize in heavy-duty vehicles, including a vast array of diesel tanker trucks for sale. They allow you to filter by make, model, year, capacity, and location.

- Online Auction Houses: Platforms such as Ritchie Bros. Auctioneers and IronPlanet frequently feature fleet liquidations and individual sales of tanker trucks. These can offer competitive pricing, but require quick decision-making and thorough pre-bidding due diligence.

3. Private Sellers

Direct purchases from private sellers, often individual owner-operators or smaller companies upgrading their fleets, can sometimes yield excellent deals.

- Advantages: Potentially lower prices due to reduced overhead compared to dealerships. Direct communication with the previous owner can provide valuable insights into the truck’s history and performance.

- Disadvantages: Requires significantly more due diligence on your part, including arranging inspections and handling all paperwork. Less recourse if issues arise post-purchase.

4. Fleet Sales & Auctions

Large companies or government agencies often sell off parts of their fleets through dedicated auctions or direct sales when upgrading or downsizing.

- Opportunities: These sales can be a treasure trove for well-maintained vehicles that have been part of a rigorous preventative maintenance program. You might find several similar trucks, ideal for expanding an existing fleet.

The Inspection Process: Don’t Buy Blindly

Regardless of where you find your diesel tanker truck for sale, a rigorous inspection process is non-negotiable. This is especially true for used vehicles, where hidden issues can quickly turn a good deal into a costly nightmare.

Pre-Purchase Inspection (PPI): Your Best Defense

A professional pre-purchase inspection (PPI) by an independent, qualified mechanic specializing in heavy-duty trucks and tankers is the single most important step you can take. This expert evaluation can uncover mechanical issues, structural damage, or regulatory non-compliance that might not be obvious during a casual viewing.

Pro tips from us: Never rely solely on the seller’s description or even a dealership’s "certified" inspection. An independent PPI ensures an unbiased assessment of the vehicle’s true condition. Insist on a road test under various load conditions if possible.

Key Areas to Inspect: A Detailed Breakdown

During the inspection, pay meticulous attention to these critical components:

- Engine and Drivetrain: Check for leaks, unusual noises, exhaust smoke, and proper fluid levels. Assess the condition of the turbocharger, fuel system, and cooling system. A dyno test can reveal engine performance issues.

- Transmission and Brakes: Evaluate gear shifting smoothness, clutch operation (if manual), and brake effectiveness. Inspect brake pads, drums/rotors, air lines, and ABS components.

- Tank Integrity: This is paramount. Look for any signs of leaks, cracks, dents, corrosion, or weld failures on the tank shell. Inspect internal baffles (if accessible) and the tank lining. Check the condition of all manholes and relief valves.

- Piping, Valves, and Hoses: Examine all external and internal piping for leaks, corrosion, and damage. Test all valves for proper operation. Hoses should be free of cracks, bulges, or excessive wear, and within their service life dates.

- Chassis, Suspension, and Tires: Inspect the frame for cracks or signs of repair. Check the leaf springs, air bags, shock absorbers, and tie rod ends. Tire condition (tread depth, even wear, sidewall integrity) is crucial for safety and operational cost.

- Electrical Systems: Verify all lights (headlights, tail lights, markers), gauges, and dashboard controls are functional. Check the condition of the battery, alternator, and wiring harness.

- Safety Features: Confirm all emergency shut-offs, vapor recovery systems, and spill prevention devices are operational and properly maintained.

- Documentation: Review the truck’s title, registration, and, most importantly, its complete maintenance history. Look for records of tank inspections, pressure tests, and HAZMAT certifications. This documentation proves compliance and reveals the truck’s past care.

Common mistakes to avoid are rushing the inspection, not hiring an independent specialist, or overlooking critical safety and compliance documentation. A thorough inspection can save you tens of thousands in future repairs and potential liability.

Understanding the Cost: More Than Just the Sticker Price

When budgeting for a diesel tanker truck, it’s vital to look beyond the initial purchase price. The total cost of ownership (TCO) includes a range of expenses that accrue over the vehicle’s lifespan.

1. Purchase Price

- New Trucks: Can range from $150,000 to over $350,000, depending on chassis, tank capacity, materials, and specialized equipment.

- Used Trucks: Prices vary wildly based on age, mileage, condition, and specifications. You might find older models for under $50,000, while newer, well-maintained used trucks can still command upwards of $150,000.

2. Operating Costs

These are the ongoing expenses that impact your profitability:

- Fuel: Diesel consumption is a major expense. Consider the truck’s fuel efficiency, especially when fully loaded.

- Insurance: Commercial vehicle insurance for HAZMAT transport is expensive due to the high liability. Rates vary based on your driving record, cargo, and coverage limits.

- Maintenance & Repairs: Routine servicing, preventative maintenance, and unexpected repairs can add up. Older trucks typically incur higher repair costs.

- Tires: A significant recurring expense, especially for heavy-duty applications.

- Driver Wages & Benefits: If you’re hiring a driver, their compensation package will be a substantial operational cost.

3. Compliance Costs

Adhering to regulations involves several recurring expenses:

- Inspections & Certifications: Regular DOT inspections, HAZMAT endorsements, tank pressure tests, and calibration of metering equipment are mandatory and come with associated fees.

- Permits & Licenses: Depending on your operating region and cargo, you may need various permits and special licenses.

- Upgrades: Sometimes, older trucks may require upgrades to meet new environmental or safety regulations.

4. Financing Options

Few businesses pay cash for commercial vehicles. Understanding financing is crucial:

- Commercial Loans: Traditional bank loans or specialized commercial vehicle lenders.

- Leasing: Operating leases (off-balance sheet, lower monthly payments) or finance leases (path to ownership).

- Vendor Financing: Some dealerships offer their own financing programs.

Internal Link: To dive deeper into managing these significant investments, read our article: "Financing Your Commercial Vehicle: A Comprehensive Guide to Loans and Leases" (Replace with actual internal link).

Legal and Regulatory Landscape for Tanker Trucks

Operating a diesel tanker truck is heavily regulated due to the inherent risks associated with transporting hazardous materials. Compliance is not optional; it’s a fundamental requirement that protects your business, your drivers, and the public.

- Department of Transportation (DOT) Regulations: These cover everything from vehicle maintenance standards and driver hours of service to load securement and accident reporting. Regular DOT inspections are mandatory.

- HAZMAT Regulations: Specific rules govern the classification, packaging, labeling, placarding, and transportation of hazardous materials like diesel fuel. Drivers must possess a Commercial Driver’s License (CDL) with a HAZMAT endorsement.

- Environmental Protection Agency (EPA) Regulations: These often relate to emissions standards for the truck’s engine and spill prevention/response plans for the cargo.

- State and Local Laws: Beyond federal regulations, individual states and municipalities may have additional requirements regarding routes, permits, and specific equipment.

Common mistakes to avoid are overlooking specific state or local requirements, failing to properly train drivers on HAZMAT procedures, or neglecting regular updates to compliance documentation. Ignorance of the law is no excuse, and non-compliance can lead to hefty fines, operational shutdowns, and severe legal repercussions.

Maintaining Your Investment: Longevity and Safety

Proper maintenance is the cornerstone of safe, efficient, and profitable tanker truck operations. It extends the life of your asset, minimizes downtime, and ensures regulatory compliance.

1. Routine Maintenance Schedule

Adhere strictly to manufacturer-recommended service intervals for the engine, transmission, brakes, and other chassis components. This includes:

- Regular oil and filter changes.

- Lubrication of chassis components.

- Inspection of belts, hoses, and fluid levels.

- Brake system checks and adjustments.

- Tire rotations and pressure checks.

2. Tank-Specific Maintenance

The tank itself requires specialized care:

- Cleaning: Regular interior cleaning, especially if cargo types change or to prevent sludge buildup.

- Inspection: Periodic internal and external inspections for corrosion, cracks, or damage.

- Pressure Testing: Regular hydrostatic or pneumatic pressure tests to ensure tank integrity.

- Valve and Gasket Checks: Ensure all valves are operating correctly and gaskets are not worn or leaking.

3. Driver Training

A well-trained driver is your best asset for maintenance and safety. They are the first line of defense against potential issues.

- Pre-Trip & Post-Trip Inspections: Emphasize thorough daily inspections as mandated by DOT.

- HAZMAT Protocols: Continuous training on safe loading, unloading, emergency procedures, and spill response.

- Defensive Driving: Training to handle the unique dynamics of a loaded tanker truck.

Internal Link: For more in-depth advice on keeping your fleet in top condition, refer to our article: "Essential Maintenance Tips for Heavy-Duty Trucks: Maximizing Uptime and Longevity" (Replace with actual internal link).

Conclusion: Making Your Informed Purchase

The journey to finding the ideal Diesel Tanker Trucks For Sale is multifaceted, requiring diligence, research, and a clear understanding of your operational needs. From assessing the market demand to navigating complex regulations and financing, every step is crucial in securing an asset that will reliably serve your business for years to come.

By meticulously evaluating new versus used options, understanding tank specifications, scrutinizing chassis and engine details, and prioritizing safety and compliance, you empower yourself to make a truly informed decision. Remember, the initial purchase price is just one piece of the puzzle; the total cost of ownership, operational efficiency, and regulatory adherence will ultimately define the success of your investment.

We hope this comprehensive guide has provided you with the valuable insights needed to confidently navigate the market. Take your time, conduct thorough inspections, and consult with experts. The right diesel tanker truck is out there, ready to become a powerful engine for your business’s growth.