Elevate Your Business: The Ultimate Guide to Finding the Best Used Scissor Lift Trucks For Sale

Elevate Your Business: The Ultimate Guide to Finding the Best Used Scissor Lift Trucks For Sale Typestruck.Guidemechanic.com

In today’s fast-paced industrial and construction environments, having the right equipment can make all the difference. Scissor lifts are indispensable tools, providing safe and efficient elevated work platforms for countless tasks, from routine maintenance and inventory management to complex construction projects. However, the investment in new machinery can be substantial, often posing a significant barrier for businesses, especially those just starting or looking to expand on a budget.

This is precisely where the market for used scissor lift trucks for sale becomes incredibly appealing. Opting for a pre-owned unit offers a practical, cost-effective solution without compromising on performance or safety, provided you know what to look for. This comprehensive guide will walk you through everything you need to know, transforming you into an expert buyer ready to make an informed decision. Our goal is to equip you with the knowledge to secure a high-quality, reliable used scissor lift that perfectly meets your operational needs and budget.

Elevate Your Business: The Ultimate Guide to Finding the Best Used Scissor Lift Trucks For Sale

Why Consider Used Scissor Lift Trucks? The Smart Investment

Choosing a used scissor lift isn’t just about saving money; it’s a strategic business decision that offers multiple advantages. Many companies, from small contractors to large corporations, consistently turn to the used market for their equipment needs. This approach allows them to maximize their capital while still acquiring top-tier machinery.

Significant Cost Savings

The most immediate and obvious benefit is the substantial reduction in purchase price. A used scissor lift can often be acquired for a fraction of the cost of a brand-new model, sometimes saving tens of thousands of dollars. This allows businesses to allocate capital to other critical areas, such as staffing, training, or project development. These savings can significantly impact your bottom line, making projects more profitable.

Immediate Availability and Proven Performance

Unlike new equipment, which can have long lead times due to manufacturing and shipping, used scissor lifts are typically available for immediate purchase and deployment. This is crucial for urgent projects or when unexpected equipment needs arise. Furthermore, many used models have a proven track record, meaning their performance and reliability have already been tested in real-world scenarios. You’re buying equipment that has already demonstrated its capabilities.

Slower Depreciation

New equipment experiences its steepest depreciation in the first few years of ownership. By purchasing a used scissor lift, you largely bypass this initial depreciation hit. The equipment will hold its value better over your ownership period, potentially offering a higher resale value down the line. This financial stability makes used equipment a more predictable asset.

Sustainable and Environmentally Friendly Choice

In an era of increasing environmental awareness, buying used equipment is also a sustainable practice. It extends the lifecycle of machinery, reducing the demand for new manufacturing and the associated consumption of raw materials and energy. Opting for used machinery contributes to a circular economy, minimizing waste and promoting resource efficiency. It’s a responsible choice for your business and the planet.

Based on my experience, many businesses overlook the incredible value and strategic advantages offered by the used equipment market. A well-maintained used scissor lift can perform just as reliably as a new one, delivering exceptional ROI for years to come.

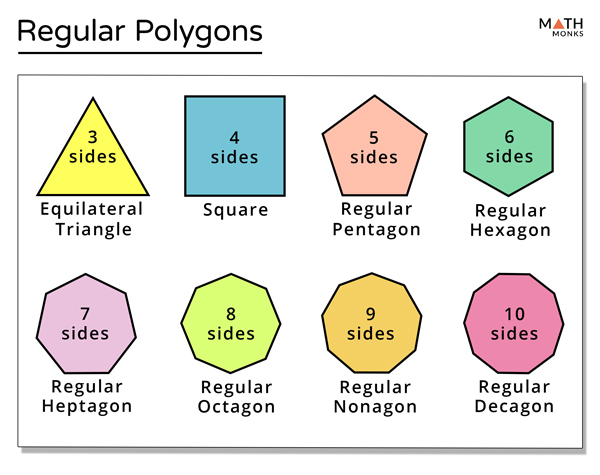

Understanding Scissor Lifts: Types and Their Applications

Before you dive into the market for used scissor lift trucks for sale, it’s essential to understand the different types available and their ideal applications. Scissor lifts are versatile machines, but choosing the right one for your specific tasks is paramount for efficiency and safety. Each type is engineered with particular work environments and performance requirements in mind.

Electric Scissor Lifts

Electric scissor lifts are the workhorses of indoor environments. They are powered by rechargeable batteries, making them quiet, emission-free, and ideal for use in warehouses, retail stores, offices, and any location where noise and air quality are concerns. Their compact design often allows them to navigate tight aisles and doorways with ease.

These lifts typically feature non-marking tires to protect sensitive flooring and offer various platform heights and weight capacities. They are perfectly suited for tasks like inventory stocking, HVAC maintenance, electrical work, and interior finishing. Their smooth, precise controls allow for careful maneuvering in confined spaces.

Rough Terrain Scissor Lifts (Diesel/Bi-Fuel)

When the job takes you outdoors and onto uneven or challenging surfaces, rough terrain scissor lifts are your go-to option. These robust machines are powered by diesel engines or bi-fuel systems, providing the necessary power and torque for demanding environments. They are equipped with heavy-duty, often foam-filled or pneumatic tires with aggressive treads, ensuring superior traction and stability on dirt, gravel, mud, and inclines.

Rough terrain models are built for construction sites, outdoor maintenance, heavy-duty industrial applications, and events. They often come with four-wheel drive and oscillating axles to maintain platform stability on slopes. Their larger platforms and higher weight capacities also make them suitable for lifting multiple workers and substantial amounts of tools and materials.

Hybrid Scissor Lifts

A newer innovation, hybrid scissor lifts combine the benefits of both electric and rough terrain models. They feature an electric motor for quiet, emission-free operation indoors or in sensitive areas, coupled with a diesel engine for extended outdoor use or recharging the batteries. This versatility makes them an excellent choice for businesses that operate in both indoor and outdoor environments.

Pro tips from us: Always match the lift type to your primary work environment and the specific tasks you’ll be performing. Overlooking this fundamental step is a common mistake that can lead to inefficient operations or even safety hazards. Consider not only the maximum height needed but also the platform capacity and the type of terrain.

The Comprehensive Pre-Purchase Checklist: What to Look For When Buying Used Scissor Lift Trucks

Buying a used scissor lift requires a meticulous inspection process. Don’t rush this stage; a thorough evaluation can save you from costly repairs and unexpected downtime in the future. This checklist will guide you through the critical areas to examine when exploring used scissor lift trucks for sale.

1. Visual Inspection: Exterior & Structural Integrity

Start with a complete walk-around, paying close attention to the overall condition of the machine. The exterior can tell you a lot about how the lift has been maintained and used.

- Frame and Chassis: Look for any signs of bending, cracks, or welds that appear to be repairs. These could indicate structural damage from overloading or impacts. Pay particular attention to stress points and joints. The integrity of the frame is paramount for safety.

- Platform and Guardrails: Inspect the platform floor for excessive wear, damage, or corrosion. Ensure the guardrails are straight, securely attached, and free from significant dents or bends. All safety decals should be present and legible. A damaged platform can compromise operator safety.

- Hydraulic Hoses and Cylinders: Examine all hydraulic lines, fittings, and cylinders for leaks, cracks, chafing, or signs of dry rot. Even minor leaks can indicate underlying problems with the hydraulic system, which is the heart of the lift’s operation. Check for corrosion on cylinder rods.

- Tires: Assess the condition of the tires. For electric lifts, non-marking solid tires should be free from chunks or severe wear. For rough terrain models, check the tread depth, sidewall integrity, and ensure there are no punctures or excessive cracking. Proper tire condition is crucial for stability and traction.

- Paint Condition: While cosmetic, the paint can offer clues. Excessive rust or multiple layers of patchy paint might conceal deeper issues. A well-maintained paint job often suggests a machine that has been cared for.

- Axles and Steering Components: For rough terrain models, check the axles for bends or damage, and inspect steering linkages for excessive play or wear.

Common mistakes to avoid are rushing the visual inspection or being swayed by a fresh coat of paint. Dig deeper; superficial aesthetics can hide critical mechanical issues.

2. Functional Inspection: Controls & Operation

Once the visual check is complete, it’s time to test the lift’s functionality. This is where you truly assess its operational health.

- Start-up and Engine (for rough terrain): For diesel or bi-fuel models, start the engine. Listen for unusual noises, knocking, or excessive smoke from the exhaust. Check for any fluid leaks after the engine has run for a few minutes. Ensure all gauges and warning lights function correctly.

- Battery (for electric): If it’s an electric model, check the battery compartment. Look for corrosion on terminals, ensuring the battery cells are not bulging. If possible, test the battery charge and its ability to hold a charge. A weak battery can severely limit operational time.

- Controls (Platform & Ground): Test all controls from both the ground and the platform. Ensure the joystick moves smoothly and precisely, and all buttons (lift, lower, drive, steer, emergency stop) are responsive. There should be no hesitation or jerky movements during operation.

- Lift and Lower Mechanism: Operate the lift through its full range of motion, both up and down. Observe for smooth, consistent movement without any jerking, shuddering, or unusual noises. The platform should extend and retract evenly. Ensure it reaches its maximum height and fully retracts.

- Drive and Steer: Drive the lift in forward and reverse, and test the steering. The lift should track straight, and the steering should be responsive without excessive play. Test the brakes for effective stopping.

- Safety Features: Crucially, test all safety features. This includes the emergency stop buttons (both on the platform and ground), horn, flashing lights, and any limit switches that prevent over-extension or tilting. Ensure the tilt sensor alarm activates if the lift is on an excessive slope.

- Levelling System: If equipped, test the automatic levelling system for the platform.

3. Documentation & History: The Paper Trail

A machine’s history is just as important as its current condition. Requesting proper documentation is a non-negotiable step.

- Maintenance Records: Ask for detailed maintenance logs. A history of regular servicing, documented repairs, and scheduled inspections indicates a well-cared-for machine. Missing records can be a red flag.

- Operating Hours: Note the hour meter reading. This gives you an indication of the machine’s overall usage, similar to mileage on a car. Compare it with the lift’s age to assess average usage.

- Service History: Inquire about any major repairs or part replacements. Understanding the lift’s repair history can reveal recurring issues or highlight components that have been recently upgraded.

- Safety Certifications: Verify that the lift meets current safety standards (e.g., ANSI in North America, CE in Europe). Ensure any required safety inspections are up-to-date.

- Operator’s Manual: Confirm that the original operator’s manual is available. This contains vital information on safe operation, maintenance schedules, and specifications.

Based on my extensive experience in equipment sales, a well-documented history is non-negotiable. It provides transparency and peace of mind, significantly reducing your risk of purchasing a problematic machine. Don’t be afraid to ask detailed questions and request proof.

Top Brands to Consider for Used Scissor Lift Trucks

When searching for used scissor lift trucks for sale, certain brands consistently stand out for their durability, reliability, and widespread availability of parts and service. Focusing on these reputable manufacturers can significantly improve your chances of finding a high-quality pre-owned unit. These brands have earned their reputation through years of engineering excellence and customer satisfaction.

JLG Industries

JLG is a global leader in access equipment, renowned for its robust construction and innovative features. Their scissor lifts are known for their strength, high lift capacities, and extended reach. JLG models, both electric and rough terrain, are built to withstand demanding job sites and offer excellent longevity. Finding parts and service for a used JLG lift is typically easy due to their extensive dealer network.

Genie Industries

Genie, a Terex Brand, is another industry giant celebrated for its user-friendly controls, reliability, and advanced technology. Genie scissor lifts often feature intuitive operating systems and thoughtful design elements that enhance productivity and operator comfort. Their diverse range of electric and rough terrain models ensures there’s a Genie lift for almost any application, making them a popular choice in the used market.

Skyjack

Skyjack is known for its simplicity, reliability, and excellent value. Their scissor lifts are often praised for their straightforward design, which translates to easier maintenance and fewer complex systems that could go wrong. If you’re looking for a dependable workhorse without unnecessary frills, a used Skyjack lift is often an economical and practical choice. They offer robust performance and are highly popular in rental fleets, attesting to their durability.

Haulotte Group

A major European manufacturer, Haulotte produces high-quality access equipment known for its robust construction and advanced safety features. Haulotte scissor lifts are designed for demanding environments and offer excellent stability and performance. Their models are increasingly popular globally, and a used Haulotte can offer European-engineered quality at a more accessible price point.

Other reputable brands like Snorkel and MEC also offer reliable used scissor lifts. Focusing your search on these established manufacturers provides a strong foundation for a sound investment.

Pricing and Value: What to Expect When Buying Used Scissor Lift Trucks

Understanding the pricing landscape for used scissor lift trucks for sale is crucial for making a smart purchase. Prices can vary significantly based on several factors, and a deeper understanding of these elements will help you determine fair market value. Don’t just look for the lowest price; consider the overall value proposition.

Factors Influencing Price

- Age and Operating Hours: Newer lifts with fewer operating hours will command higher prices. These metrics are key indicators of wear and tear, similar to mileage on a car.

- Condition: The overall mechanical and cosmetic condition plays a massive role. A well-maintained lift with minimal damage and a clear service history will naturally be more valuable.

- Brand and Model: Premium brands (like JLG, Genie) often retain their value better. Specific models known for their durability or unique features might also fetch higher prices.

- Lift Capacity and Height: Lifts with higher platform capacities and greater working heights are generally more expensive due to their enhanced capabilities.

- Features and Options: Additional features such as articulating jibs, power outlets on the platform, or specialized tires can increase the price.

- Location: Geographical location can influence pricing due to shipping costs and regional market demand.

Market Research and Negotiation Tips

Before making an offer, conduct thorough market research. Look at comparable models from various sellers to get a sense of the average price range. Websites like Equipment Trader, Machinery Trader, or even auction results can provide valuable data.

When negotiating, be prepared to walk away if the price doesn’t align with the lift’s condition and market value. Highlight any minor flaws you’ve identified during your inspection to justify a lower offer. Remember, the seller is often motivated to move inventory.

Budgeting for Potential Repairs and Maintenance

Pro tip: Don’t just focus on the lowest initial purchase price; consider the total cost of ownership. Even a well-inspected used lift might require some immediate maintenance or minor repairs. Allocate a portion of your budget for fresh fluids, filters, battery checks (for electric models), or worn-out tires. Factor in the cost of regular preventative maintenance, which is essential for prolonging the life of your investment.

Where to Find Reliable Used Scissor Lift Trucks For Sale

Finding the right seller is just as important as finding the right machine when you’re in the market for used scissor lift trucks for sale. Different sources offer varying levels of reliability, pricing, and services. Understanding these options will help you navigate the market effectively.

Authorized Dealers and Equipment Retailers

This is often the safest and most reliable route. Authorized dealers of major brands (JLG, Genie, Skyjack) frequently have certified pre-owned programs. These lifts are typically thoroughly inspected, serviced, and sometimes come with limited warranties. While prices might be slightly higher than private sales, the peace of mind, access to service, and financing options often justify the cost. They usually have expert staff who can guide you to the best model for your needs.

Online Marketplaces and Auction Houses

Websites like Equipment Trader, Machinery Trader, and IronPlanet are vast marketplaces for used construction and industrial equipment. You can find a wide range of lifts from various sellers, including dealers, rental companies, and private individuals. Be cautious with private sellers and ensure you conduct a thorough inspection before committing.

Auction houses like Ritchie Bros. Auctioneers can offer excellent deals, but purchases are typically "as-is, where-is." This means you bear all risks, and detailed inspections are even more critical. Auctions are best suited for experienced buyers who can quickly assess equipment.

Rental Companies

Many equipment rental companies regularly cycle out older units from their fleet to make way for new models. These "off-rent" machines are often well-maintained, as rental companies have strict maintenance schedules to ensure reliability for their customers. They might not offer extensive warranties, but their service history is usually well-documented. This can be a great source for reliable, used equipment that has been professionally cared for.

Based on years of connecting buyers with quality equipment, I always recommend starting with established dealers or reputable rental companies. Their commitment to quality and customer service often translates into better-maintained machines and more transparent purchasing experiences.

Post-Purchase Considerations: Safety, Maintenance, and Training

Acquiring a used scissor lift is just the first step. To maximize your investment, ensure operational safety, and prolong the life of your equipment, proper post-purchase practices are essential. These considerations are vital for any business operating aerial work platforms.

Safety First: Operator Training and Worksite Protocols

Safety must always be the top priority. Even if your used scissor lift is in excellent condition, improper operation can lead to severe accidents.

- Operator Training and Certification: All personnel operating the scissor lift must receive proper training and certification. This includes understanding the specific model, its controls, load capacities, and emergency procedures. OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) standards provide guidelines for safe operation and training requirements.

- Pre-Operation Checks: Implement a mandatory daily pre-operation inspection. This includes checking fluid levels, tire pressure, controls, emergency stop buttons, and looking for any visible damage or leaks. A simple checklist can prevent major incidents.

- Worksite Assessment: Before each use, assess the worksite for hazards such as uneven terrain, overhead obstructions, power lines, and pedestrian traffic. Ensure outriggers (if applicable) are properly deployed and the work area is cordoned off.

- Safety Decals and Manuals: Ensure all safety decals on the lift are present and legible. Keep the operator’s manual readily accessible on the machine for quick reference.

For more in-depth insights into scissor lift safety, you might want to check out our guide on Scissor Lift Safety Best Practices.

Ongoing Maintenance: Protecting Your Investment

Regular and preventative maintenance is key to extending the lifespan of your used scissor lift and avoiding costly breakdowns. A well-maintained machine will perform reliably for years.

- Scheduled Inspections: Beyond daily checks, implement weekly, monthly, and annual inspection schedules. These should be more detailed and cover components like hydraulic systems, electrical connections, structural integrity, and wear parts.

- Fluid Checks and Lubrication: Regularly check and top off hydraulic fluid, engine oil (for rough terrain models), and coolant. Lubricate all moving parts, pivot points, and bushings as recommended by the manufacturer.

- Battery Care (Electric Lifts): For electric models, ensure proper battery maintenance. This includes checking water levels (for lead-acid batteries), keeping terminals clean and corrosion-free, and following correct charging procedures to maximize battery life.

- Tire Maintenance: Monitor tire pressure (for pneumatic tires) and inspect for wear or damage. Replace worn tires promptly to maintain stability and traction.

- Professional Servicing: Schedule periodic professional servicing from qualified technicians. They can perform more complex diagnostics, calibrate systems, and identify potential issues before they become major problems.

Parts Availability

Before purchasing a used model, especially an older one, quickly check the availability of common wear parts and critical components. While major brands generally have good parts support, some very old or obscure models might pose challenges. Ensuring parts are readily available will minimize downtime in case of a repair.

For comprehensive safety standards and training resources, refer to the official OSHA website.

Conclusion: Empowering Your Purchase of Used Scissor Lift Trucks For Sale

The decision to invest in used scissor lift trucks for sale is a smart, strategic move for businesses looking to enhance their operational capabilities without the significant capital outlay of new equipment. From substantial cost savings and immediate availability to a smaller depreciation curve and environmental benefits, the advantages are clear and compelling. However, realizing these benefits hinges entirely on making an informed and diligent purchase.

By meticulously following our comprehensive pre-purchase checklist – examining structural integrity, testing all functionalities, and verifying documentation – you significantly mitigate risks. Understanding the different types of scissor lifts, recognizing top-tier brands, and knowing where to source reputable machines will further empower your decision-making. Remember to budget for ongoing maintenance and prioritize robust safety training for all operators.

With this in-depth guide, you are now equipped with the expert knowledge to confidently navigate the used scissor lift market. Your next used scissor lift isn’t just a piece of equipment; it’s a valuable asset that will elevate your projects, enhance productivity, and contribute to the long-term success of your business. Make your next investment a smart one, built on solid research and informed choices.